Method for making sausage in bladder skin

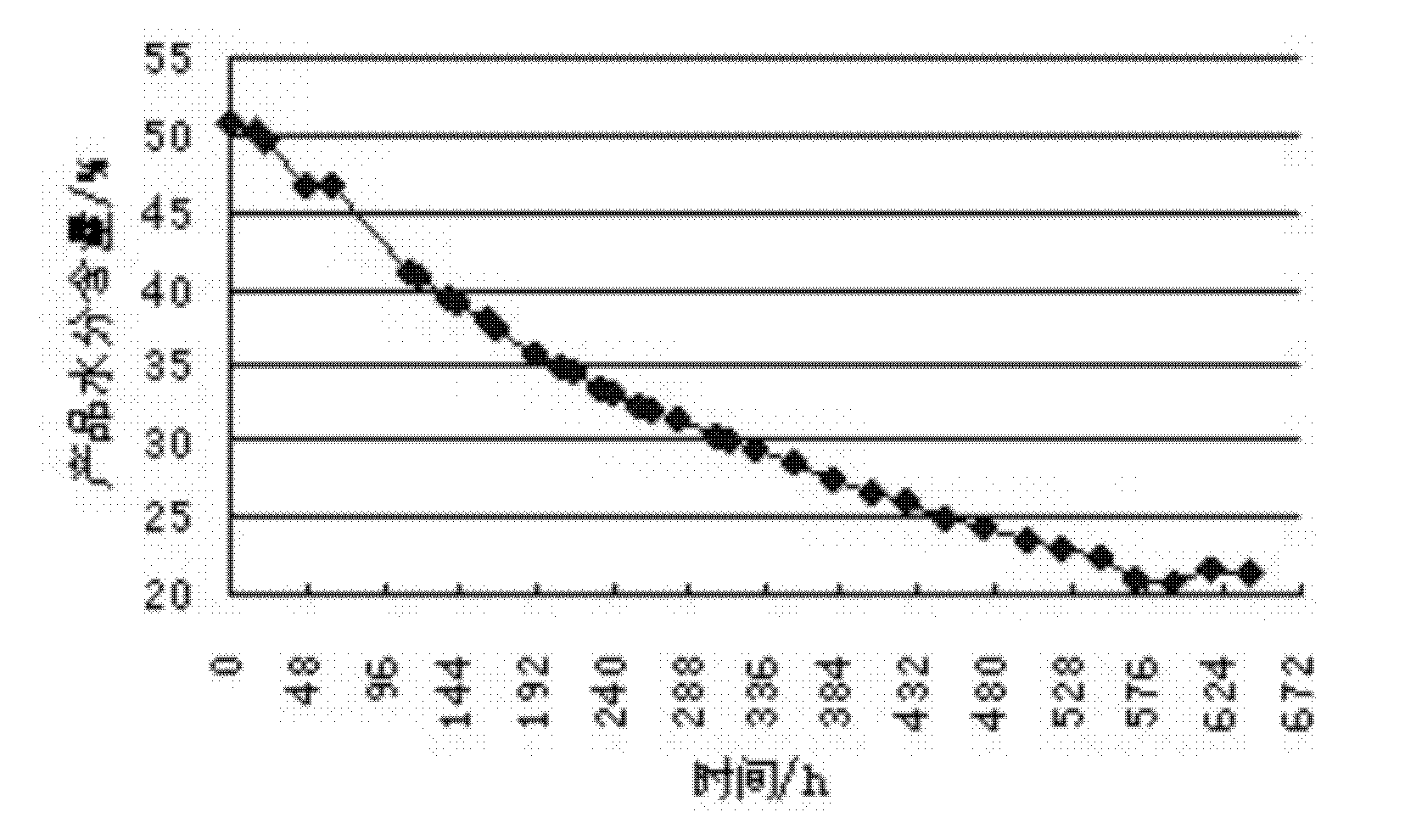

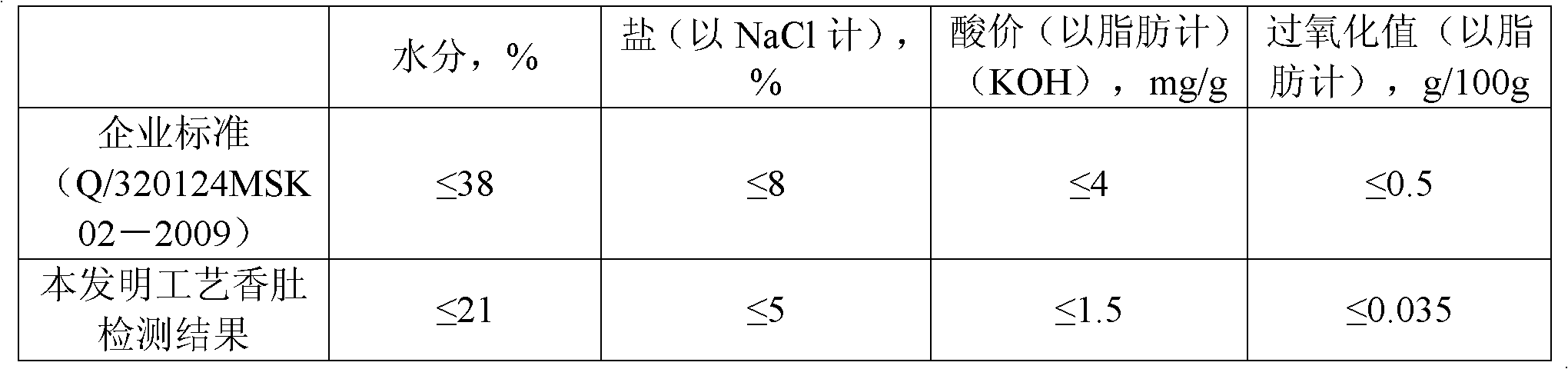

A production method and technology of sautéed tripe, which is applied in the food field and can solve the problems of hollowness, sourness of the product, loss of flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Remove the blood, fascia, scars, lymph, broken bones, dirt and foreign impurities from the thawed 4# meat, and remove the obvious fat on the surface, so that the fat-to-thin ratio is 3:17;

[0023] 2. Rinse

[0024] Rinse the lean meat with tap water for 2 hours, wash off the blood, and grind it into granules with a meat grinder (LASKA200, Austrian LASKA company) (using a double-layer sieve with an inner diameter of 13 mm and an outer diameter of 5 mm). The temperature of the meat after grinding is ≤14°C; Or cut into small pieces of 6mm×6mm×6mm with a dicing machine, and then scald them once with warm water at 56±1°C for about 1 minute. Rinse with water to cool down, and wash away surface impurities and oil stains;

[0025] 3. Mixing material

[0026] Raw meat is calculated according to 100%, salt 2.5%, sugar 10%, ice water 5%, monosodium glutamate 0.3%, white wine 1.5%, sodium erythorbate 0.04%, sodium nitrite 0.004%, weigh according to the proportion, add lean me...

Embodiment 2

[0037] 1. Raw material processing: Remove the blood, fascia, scars, lymph, broken bones, dirt and foreign impurities from the thawed 4# meat, and remove the obvious fat on the surface, so that the fat-to-thin ratio is 4:16;

[0038] 2. Rinse:

[0039] Rinse the lean meat with tap water for 2 hours, wash off the blood, and grind it into granules with a meat grinder (with a double-layer sieve of 13mm inside and 5mm outside). After the 6mm×6mm×6mm small pieces are scalded once with warm water at 56±1°C for about 1 minute, the oil slick on the surface is washed off, put the blanched fat into the rinse tank, rinse with ice water to cool down, and Wash away surface impurities and oil stains;

[0040] 3. Seasoning and marinating:

[0041] Raw meat is calculated according to 100%, salt 3.5%, sugar 4%, ice water 4%, monosodium glutamate 0.25%, white wine 1.2%, sodium erythorbate 0.03%, sodium nitrite 0.004%. Stir, first mix the lean meat with auxiliary materials and ice water, then ...

Embodiment 3

[0052]1. Remove the blood, fascia, scars, lymph, broken bones, dirt and foreign impurities from the thawed 4# meat, and remove the obvious fat on the surface, so that the fat-to-thin ratio is 2:18;

[0053] 2. Rinse

[0054] Rinse the lean meat with tap water for 2 hours, wash off the blood, and grind it into granules with a meat grinder (LASKA200, Austrian LASKA company) (using a double-layer sieve with an inner diameter of 13 mm and an outer diameter of 5 mm). The temperature of the meat after grinding is ≤14°C; Or cut into small pieces of 5mm×5mm×5mm with a dicing machine, and then scald them once with warm water at 56±1°C for about 1 minute. Rinse with water to cool down, and wash away surface impurities and oil stains;

[0055] 3. Mixing material

[0056] Raw meat is calculated according to 100%, salt 3%, sugar 8%, ice water 4.5%, monosodium glutamate 0.3%, white wine 1.4%, sodium erythorbate 0.05%, sodium nitrite 0.003%, weigh according to the proportion, add lean meat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com