Method for preparing ultrahigh pressure low-salt weever sausage

An ultra-high pressure, sea bass technology, applied in the field of food science, can solve the problems of loss of flavor, high energy consumption, and changes in nutrients, and achieve the effects of improved tenderness, low salt content, and strong water retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

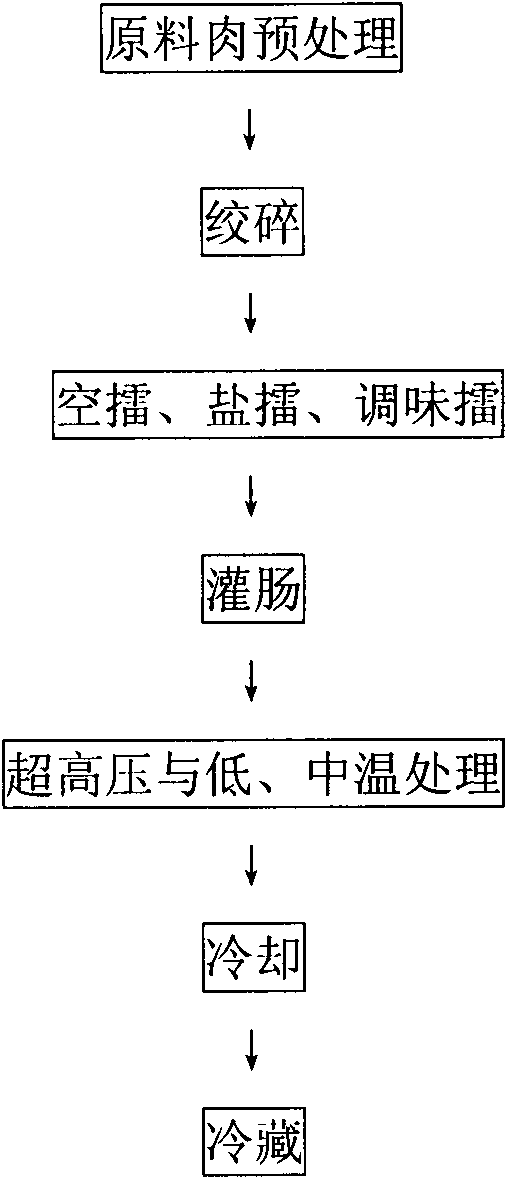

Image

Examples

example 1

[0039] 1. Remove the phosphorus, skin, viscera, connective tissue and spines of the thawed sea bass.

[0040] 2. Grind the fish for 5 minutes, then add 1-2% salt and grind for 10 minutes, and finally add 2% white sugar, 0.2% monosodium glutamate, 0.05% white pepper, 0.5% ginger powder, and 6.25% water for 10 minutes.

[0041] 3. Pour the beaten surimi into the casing and seal it.

[0042] 4. Apply a pressure of 300Mpa for 10 minutes, then heat treatment at 50°C for 10 minutes.

[0043] 5. Put the boiled product in cold water to cool it down to room temperature, and then store it at 4°C.

[0044] After testing: the appearance of the obtained perch sausage is full, without cracks, both ends are well sealed, and there is no content attached to the ligated part, and the length and thickness are basically the same; it is a high-end product that is white with the umami taste of fresh fish and no peculiar smell. After two months of storage, the volatile basic nitrogen content was 1...

example 2

[0046] 1. Remove the phosphorus, skin, viscera, connective tissue and spines of the thawed sea bass.

[0047] 2. Empty the fish for 5 minutes, then add 1-2% salt and grind for 10 minutes, finally add 3% white sugar, 0.2% monosodium glutamate, 0.1% white pepper, 1.8-2% ginger juice, 6.25% rice wine and grind for 10 minutes .

[0048] 3. Pour the beaten surimi into the casing and seal it.

[0049] 4. Apply a pressure of 400Mpa for 5 minutes, then heat treatment at 60°C for 10 minutes.

[0050] 5. Put the boiled product in cold water to cool it down to room temperature, and then store it at 4°C.

[0051] After testing: the appearance of the obtained perch sausage is full, without cracks, both ends are well sealed, and there is no content attached to the ligated part, and the length and thickness are basically the same; it is a high-end product that is white with the umami taste of fresh fish and no peculiar smell. After two months of storage, the volatile basic nitrogen conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com