High pressure liquid-liquid extraction method

A high-pressure liquid extraction technology, applied in the field of liquid-liquid extraction, can solve the problems of complex operating procedures, high cost, and difficult temperature uniformity of supercritical extraction devices, and achieve the effects of short extraction time, low labor intensity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

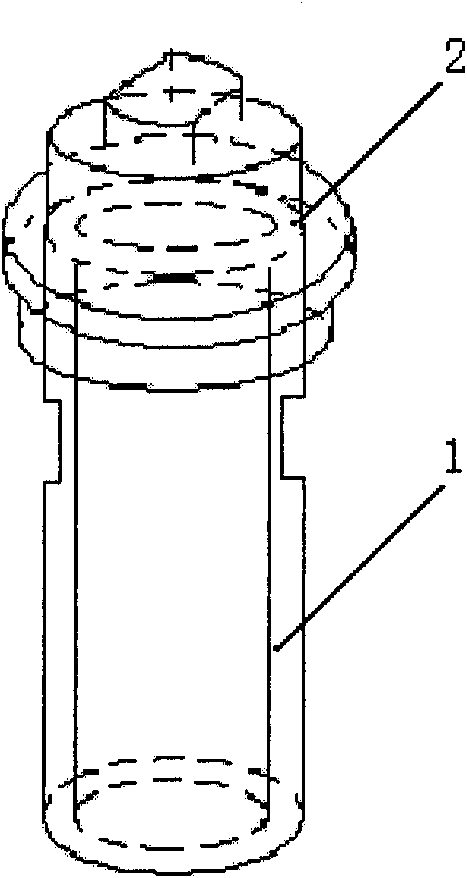

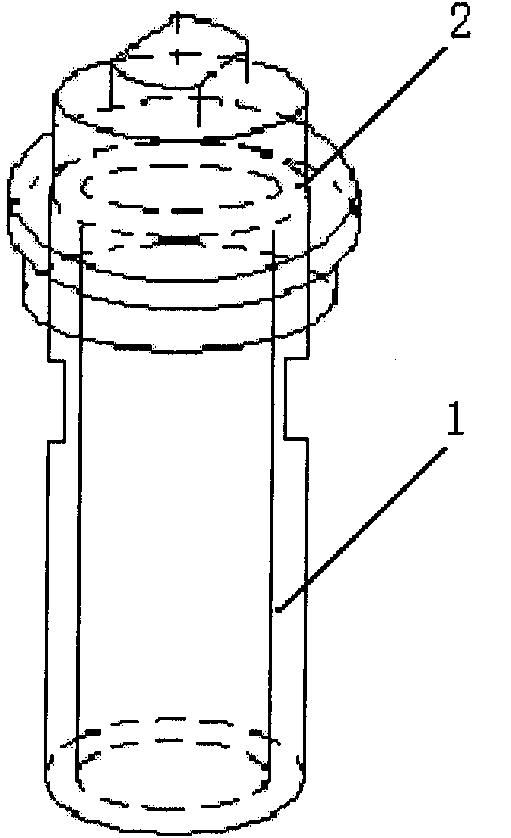

[0021] Such as figure 1 As shown, adopting this high-pressure liquid-liquid extraction method first needs to be provided with an extraction device, and this extraction device comprises a pressure-resistant container 1 and a sealing assembly 2 that can seal this pressure-resistant container, and this extraction device can be various shapes, comprises Spherical, cubic, pyramid, prism, etc. Since the extraction device needs to withstand high pressure and have good sealing performance, it needs to be made of high-strength materials such as stainless steel, cast iron and other metals. The volume of the pressure-resistant container 1 can be customized according to the needs of use, and the volume can be 1mL-1000L. The small-volume device can be used for laboratory high-pressure extraction, and the large-volume device can be used for industrial prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com