Method for controlling turbidity of initial filter water in quick filter tank after backwashing and micro-expansion washing

A control method and fast filter technology, applied to loose filter material filters, separation methods, chemical instruments and methods, etc., can solve problems such as the influence of filter water production rate, achieve water saving, simple and easy water consumption, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

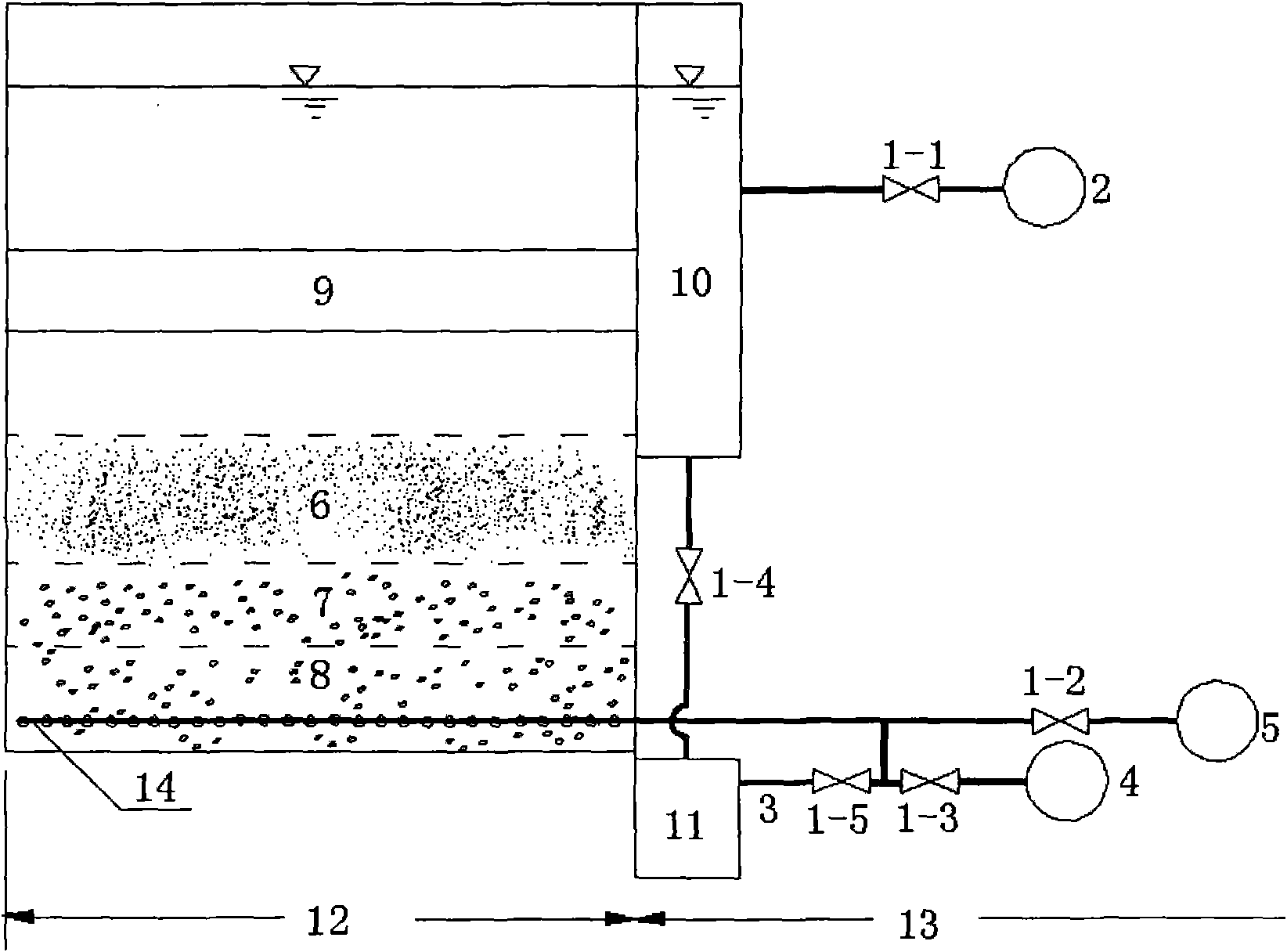

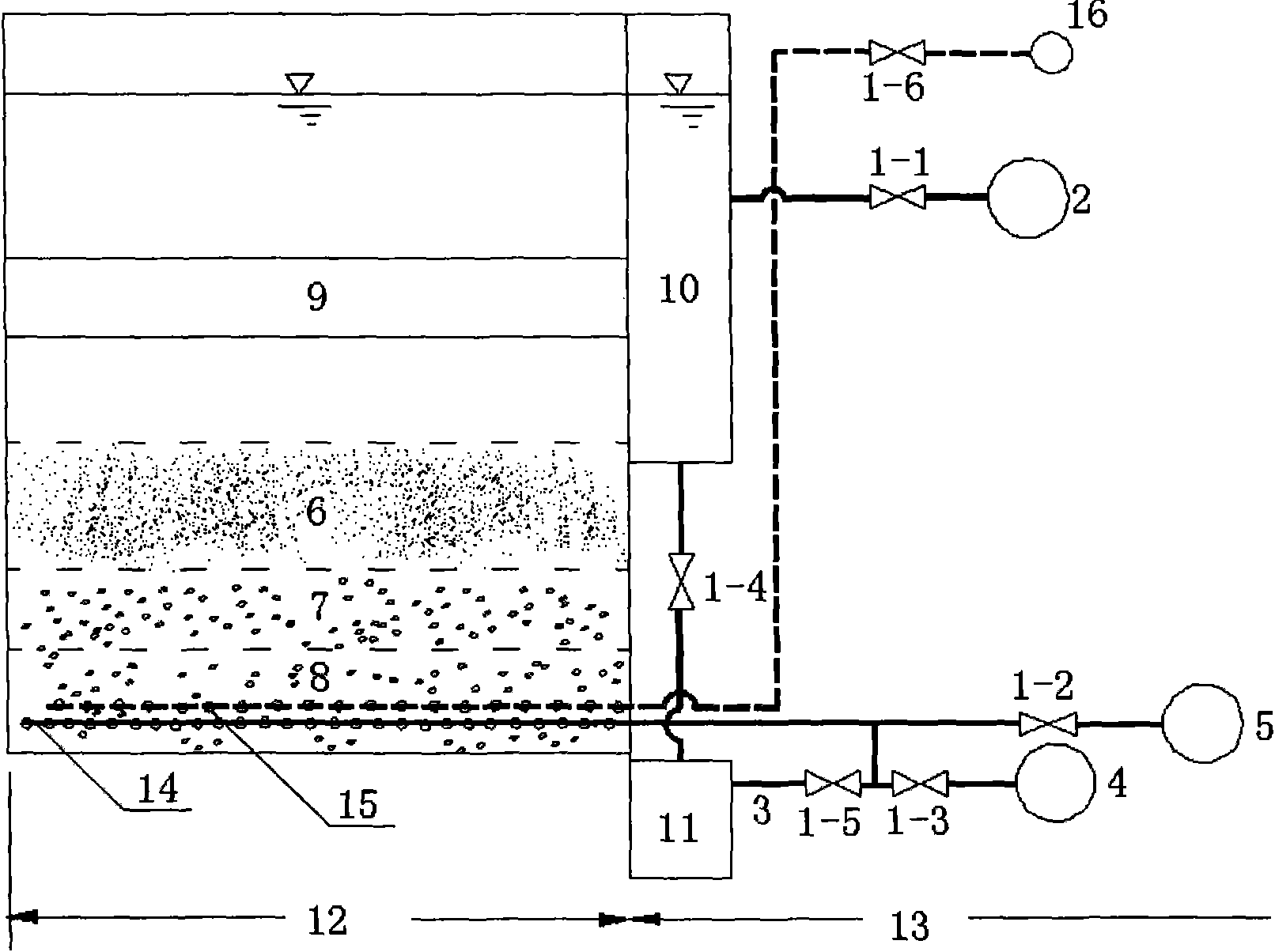

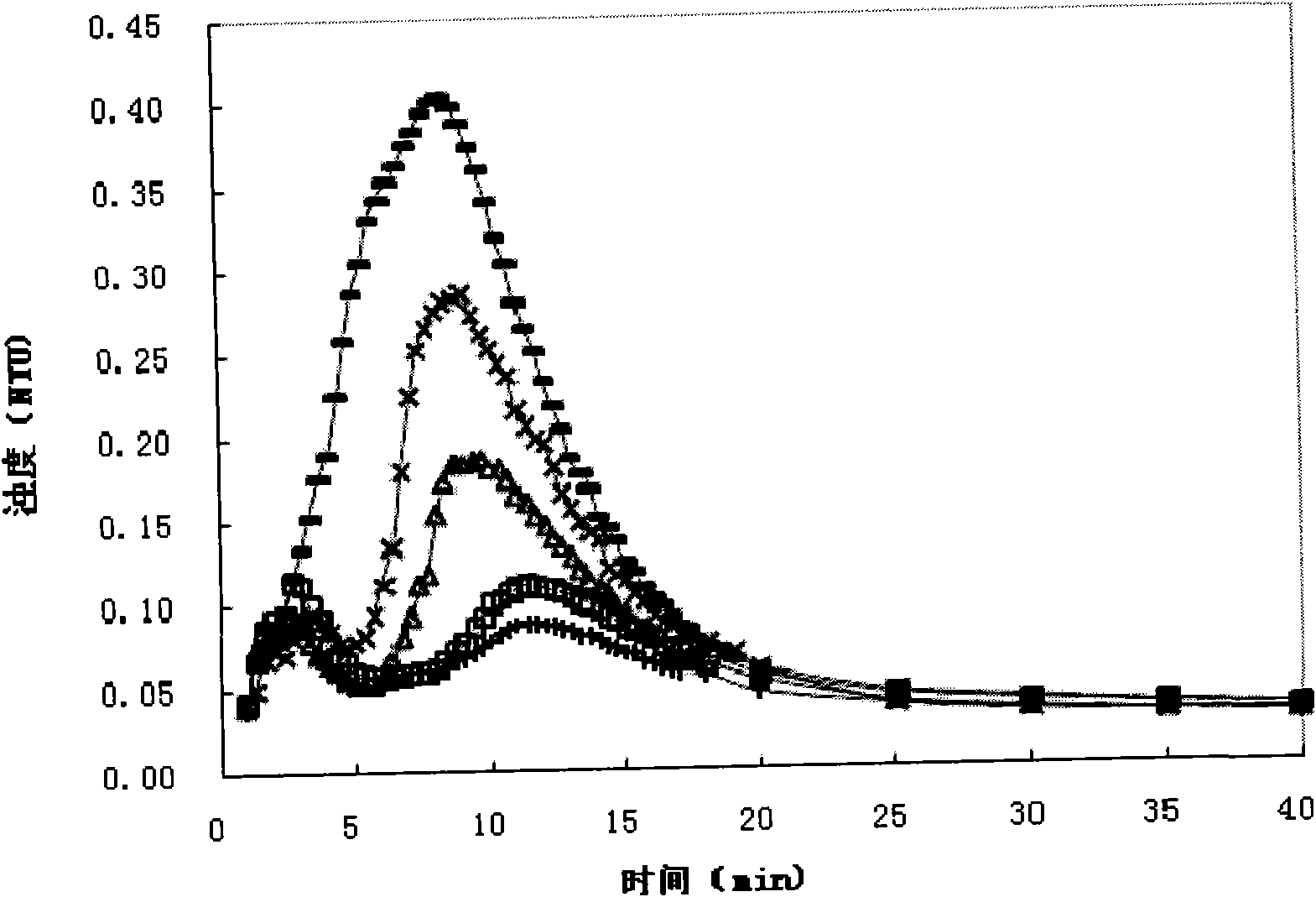

[0022] The present invention is a method for controlling the turbidity of primary filtration water in a fast filter by increasing micro-expansion flushing after backwashing, and its implementation process is characterized in that: the opening degree of the flushing water inlet valve is reduced, and the flow rate of flushing water is reduced to the expansion rate of the filter layer It is 3%-5%, and the duration of flushing needs to be determined according to the turbidity and filtration rate of the influent water during the operation of the fast filter: if the turbidity of the influent water in the fast filter is 1NTU-3NTU and the filtration rate is 6m / h-10m / h h, the micro-expansion flushing lasts for 1min-3min; if the turbidity of the inlet water of the fast filter is greater than 3NTU and the filtration rate is greater than 10m / h, the duration of micro-expansion flushing is greater than 3min and less than 7min.

[0023] 1. The embodiment of adding micro-expansion flushing aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com