Horizontal type desulfurization reactor for industrial flue gas and flue gas treatment method

An industrial flue gas and reactor technology, which is applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of system paralysis, easy scaling of swirl plates, and large airflow resistance coefficient, so as to reduce maintenance costs. , good desulfurization effect and small system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

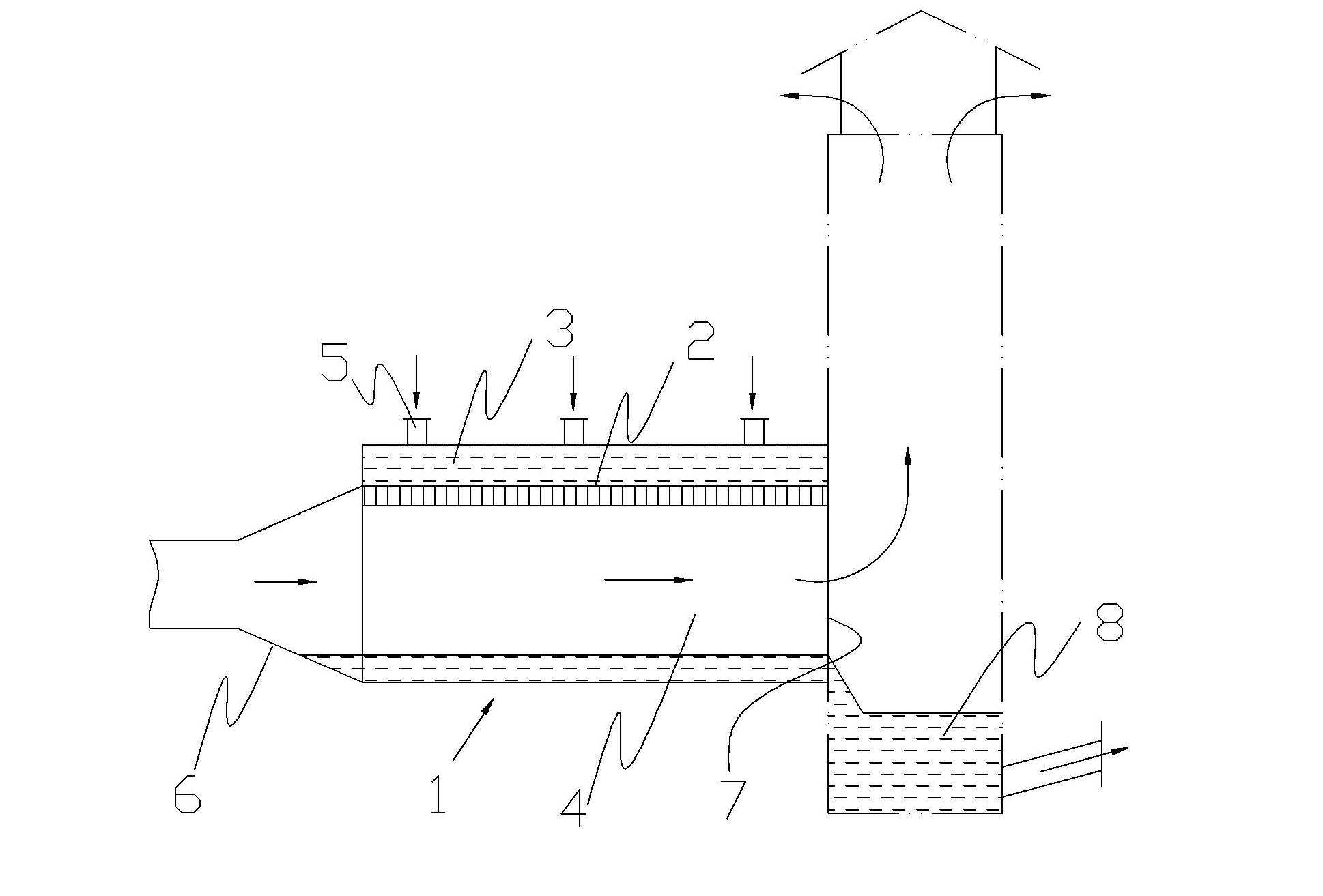

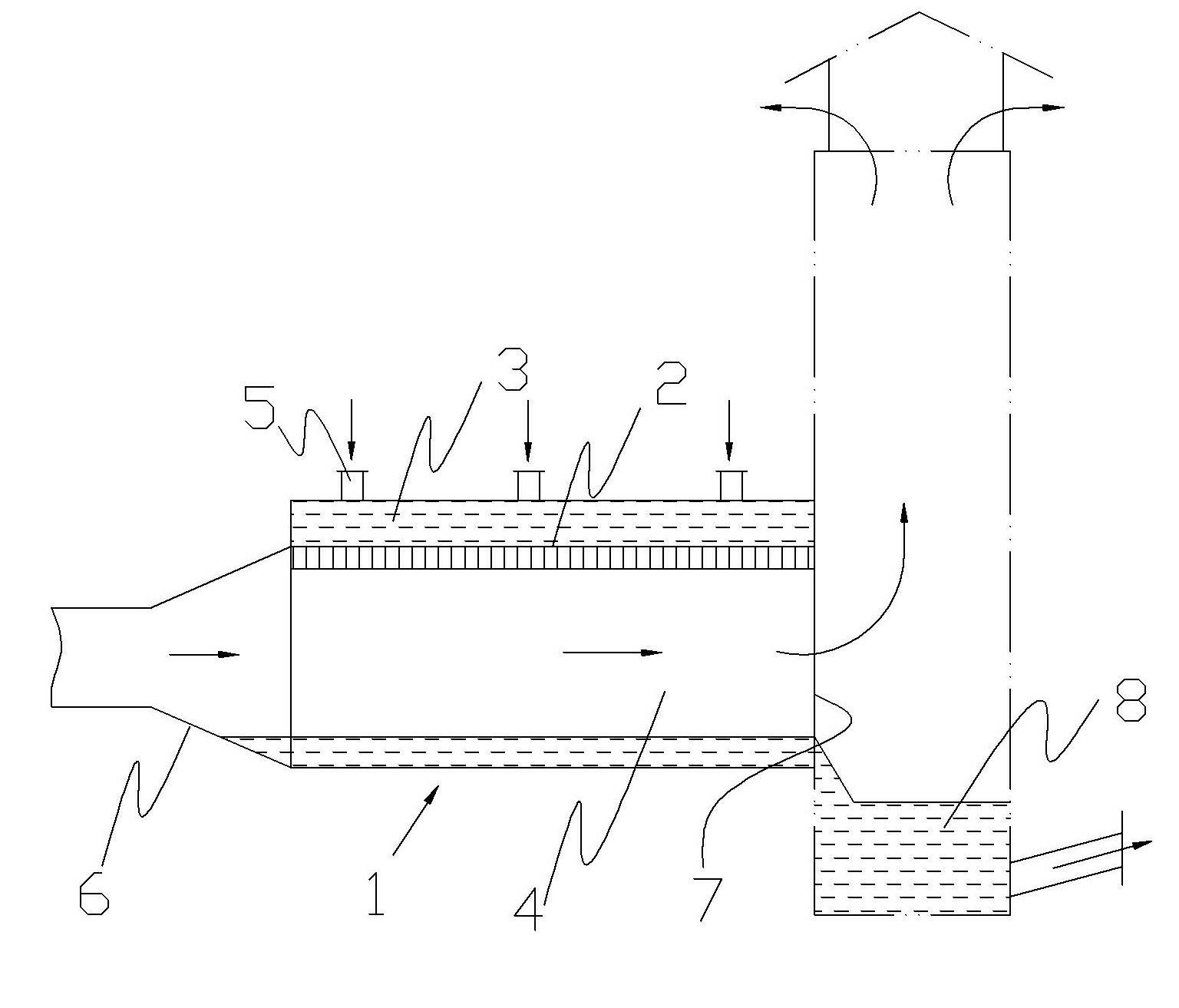

[0011] From figure 1 It can be seen that the present invention has a pipe body 1, which is placed horizontally, with a flue gas inlet 6 opening at one end and a flue gas outlet 7 opening at the other end. There is a distribution orifice 2 arranged horizontally in the pipe body 1, which divides the inner cavity of the pipe body 1 into upper and lower cavities, the upper cavity is the desulfurization liquid distribution chamber 3, and the lower cavity is the desulfurization reaction chamber 4. The top of 1 is provided with a liquid inlet 5, and the lye is injected into the desulfurization distribution chamber 3 through the liquid inlet 5 of the water pump. The method of using this industrial flue gas desulfurization reactor for flue gas treatment is: the flue gas enters the desulfurization reaction chamber 4 of the pipe body 1 horizontally from the flue gas inlet 6, and the lye in the desulfurization distribution chamber 3 is continuously downward through the distribution orific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap