LED automatic glue pouring system

A glue-filling and automatic technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as low degree of automation and work efficiency, poor potting thickness, poor uniformity and flatness of potting, and inability to guarantee the packaging effect, so as to save money. Labor cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

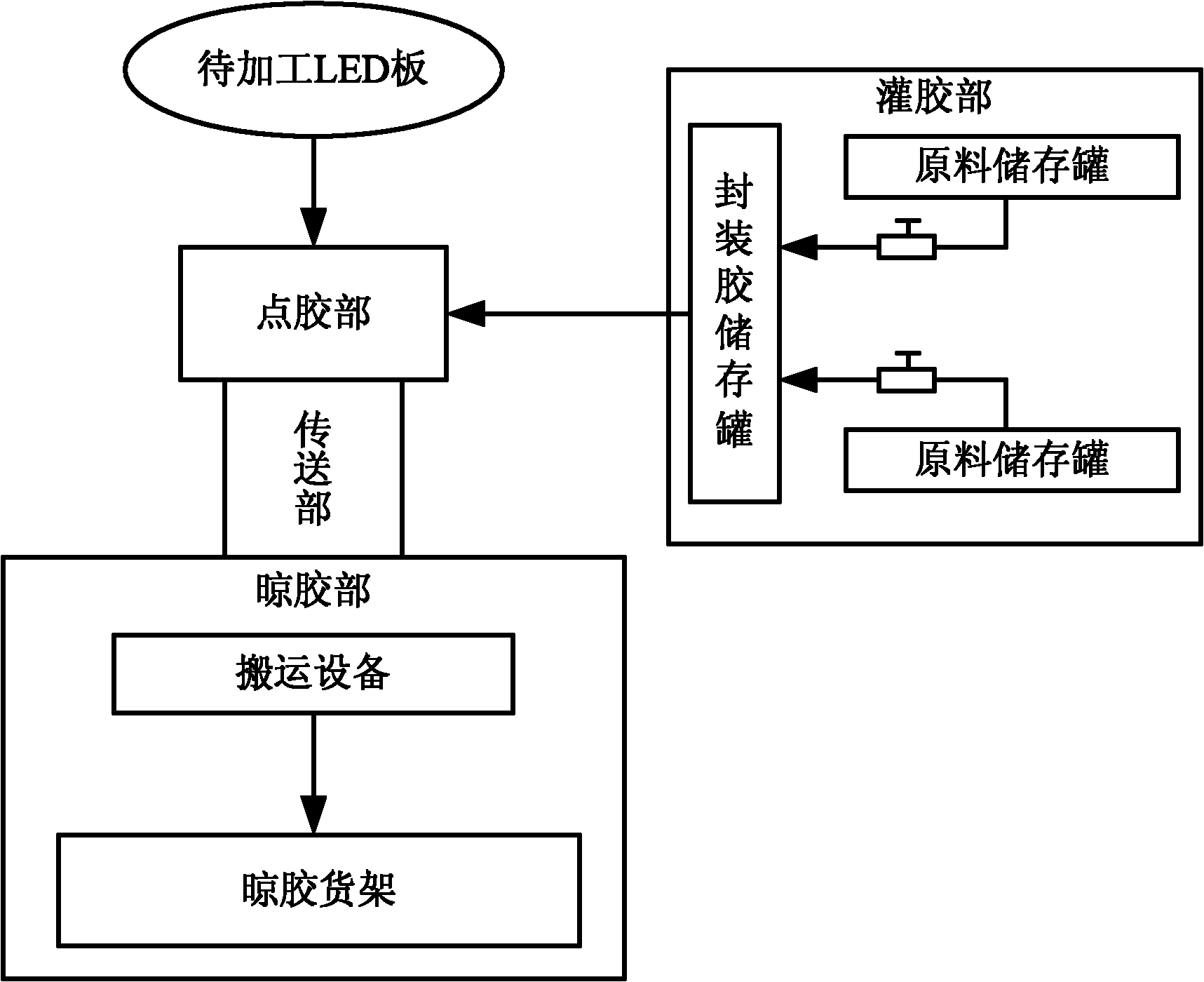

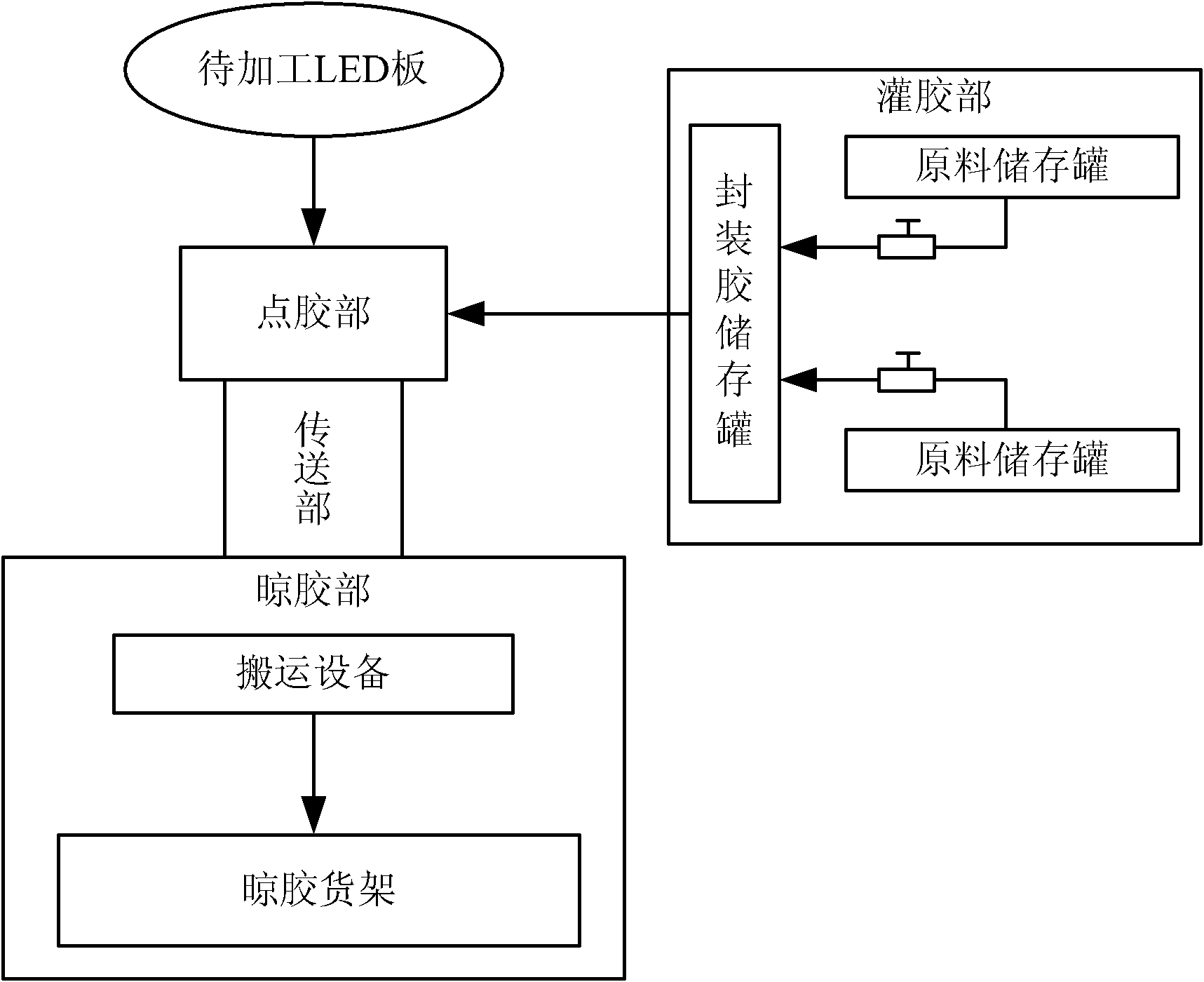

[0022] According to one embodiment of the present invention, a kind of LED automatic dispensing system is provided, such as figure 1 As shown, it mainly includes: glue filling department, glue dispensing department, glue drying department and conveying department.

[0023] Among them, the glue filling part is used to mix protective glue and diluent into packaging glue and provide it to the glue dispensing part; the glue dispensing part is used to receive the LED board to be potted and the packaging glue from the glue filling part, and to dispense glue on the LED board Potting, and providing the LED boards after dispensing and potting to the glue drying department; the glue drying department is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com