Making technology of once-moulding whole resin concrete electrolytic cell

A technology of resin concrete and production method, which is applied in the field of industrial anti-corrosion, and achieves the effects of avoiding defects, improving performance and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

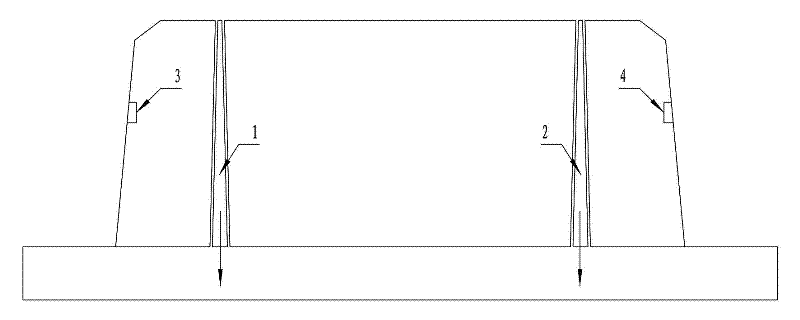

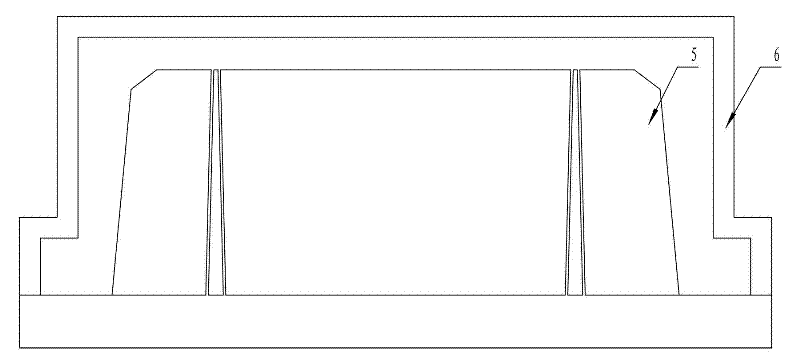

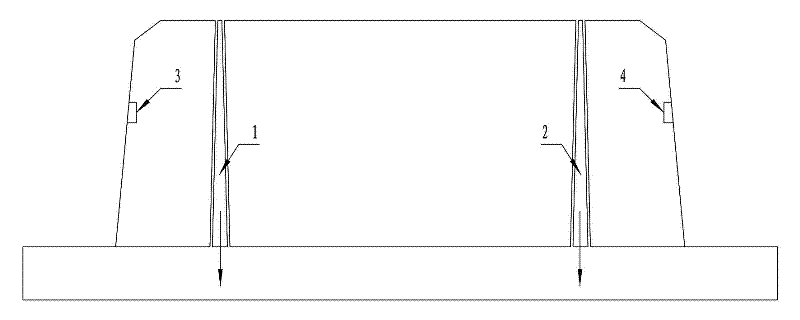

Image

Examples

Embodiment 1

[0017] The specifications are 5.7m x 1.6m x 1.75m electrolyzer mold, and there are 2 expansion joint structures in the middle of the mandrel. Install a digital display pressure sensor on the mandrel, assemble the outer mold with the mandrel, and pour resin concrete into the mould. When the resin concrete solidifies and shrinks, the reading displayed on the pressure sensor begins to increase, and when the reading reaches above 1.4MPa, the slider in the expansion joint is artificially pulled out downward. As the slider slides, the gap width of the expansion joint shrinks, and the reading on the pressure sensor also decreases. When the reading decreases to 1.0MPa, stop sliding the slider. As the resin concrete continues to solidify, the pressure will increase again. Use the same method as above to adjust the pressure by sliding the slider, and so on, and always control the pressure within the range of 1.0~1.4MPa until the electrolytic cell is completely solidified.

Embodiment 2

[0019] The specifications are 5.9m x 1.2m x 1.9m electrolyzer mold, and there are 3 expansion joint structures in the middle of the mandrel. A pressure sensor that can be connected to the automatic controller is installed on the mandrel, and the pressure sensor is connected with the automatic controller through a data line, and the automatic controller is connected with the hydraulic system installed on the slider. The range of automatic controller setting is 0.9~1.1MPa. After the outer mold is assembled, it is assembled with the core mold, and the resin concrete is poured into the mold. When the resin concrete solidifies and shrinks, the pressure on the mandrel increases. When the pressure exceeds 1.1MPa, the automatic controller automatically starts the hydraulic system to make the slider slide, and stops sliding when the pressure is less than 0.9MPa. Automatically control the pressure on the mandrel during the entire curing process by adjusting the sliding of the slider to...

Embodiment 3

[0021] The specifications are 2.8m x 0.8m x 0.9m electrolytic cell mold, and there is an expansion joint structure in the middle of the mandrel. A pressure sensor that can be connected to the automatic controller is installed on the mandrel, and the pressure sensor is connected with the automatic controller through a data line, and the automatic controller is connected with the hydraulic system installed on the slider. The range of automatic controller setting is 0.7~0.9MPa. After the outer mold is assembled, it is assembled with the core mold, and the resin concrete is poured into the mold. When the resin concrete solidifies and shrinks, the pressure on the mandrel increases. When the pressure exceeds 0.9MPa, the automatic controller automatically starts the hydraulic system to make the slider slide, and stops sliding when the pressure is less than 0.7MPa. Automatically control the pressure on the mandrel during the entire curing process by adjusting the sliding of the slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com