Oil palm fruit distribution rolling forming system

A technology for oil palm fruit and molding machine, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of difficulty in large diameter, low yield, uneven feeding, etc., and achieves low cost, high yield, The effect of improving the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

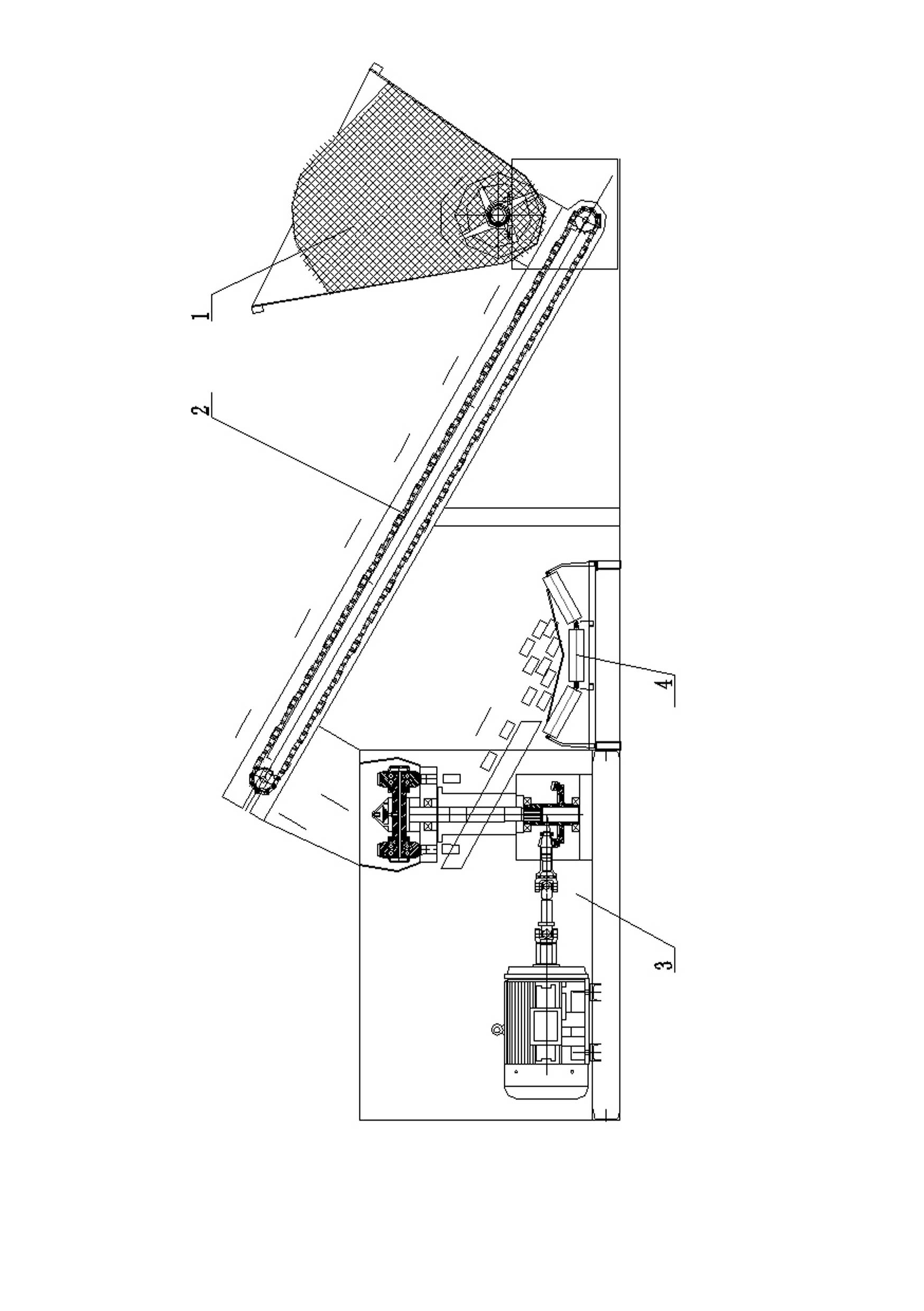

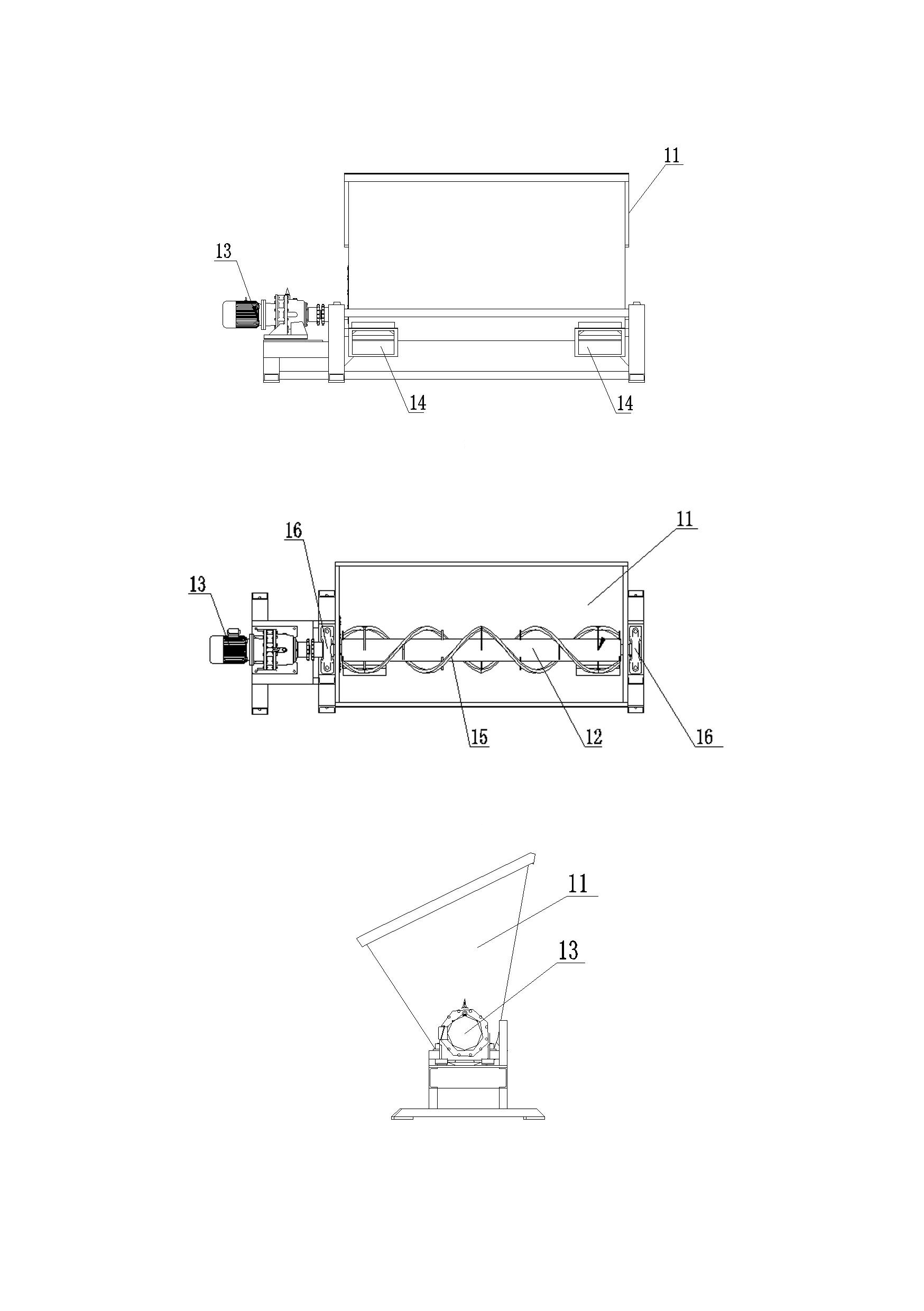

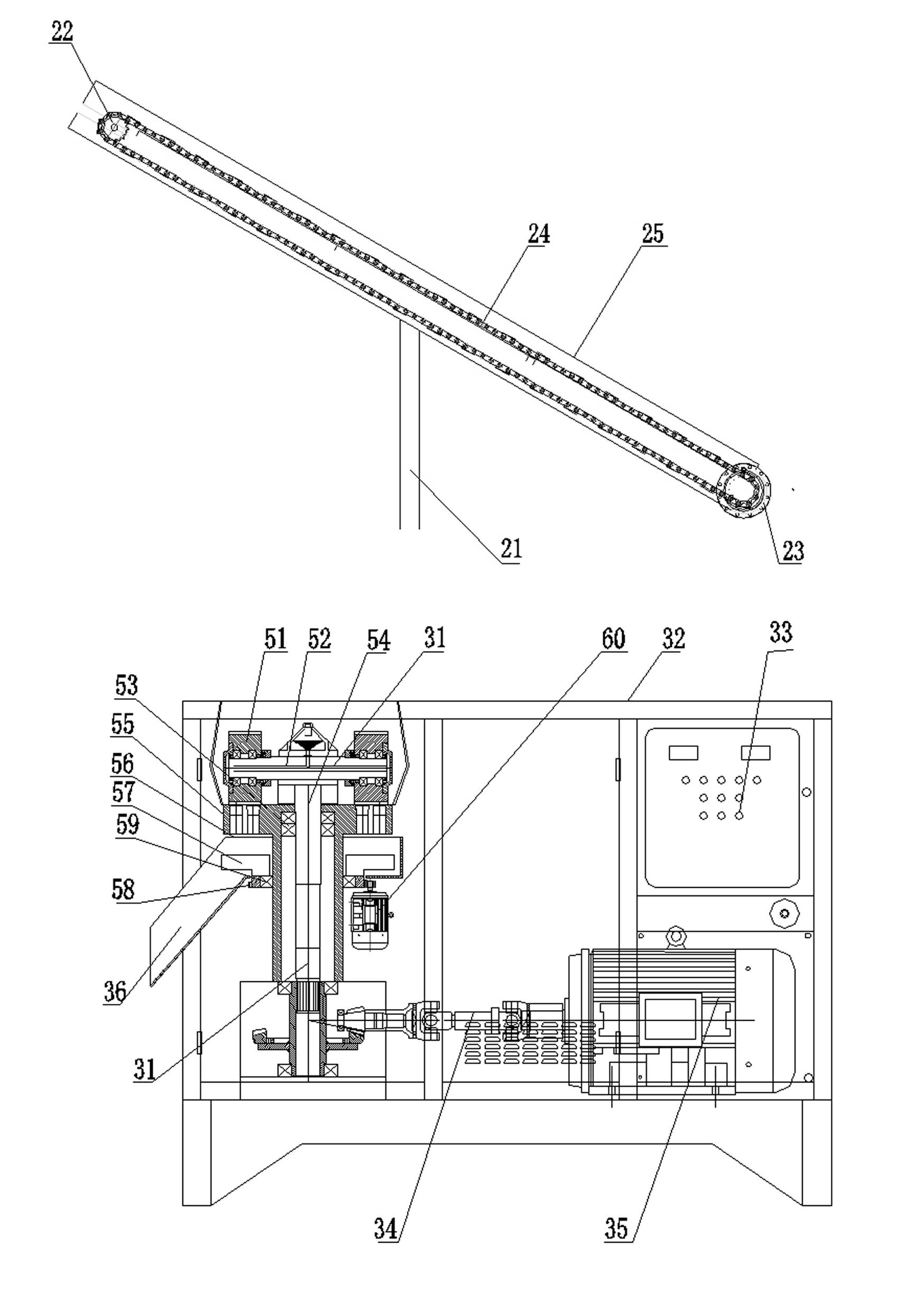

[0020] As shown in Figure 1: the present invention is by stirring material feeder 1, feeding device 2, roller compacting machine 3, discharge device 4: the feeding end of feeding device is arranged on the outlet 14 below stirring material feeding machine, feeds The discharge end of the device is located above the feed port of the rolling forming machine, and a sealed feed hopper is provided between the discharge end of the feeding device and the feed port of the rolling forming machine, and the lower opening of the feed hopper is fixed on the The edge of the feed port of the forming machine, and the discharge device is arranged at the discharge port of the rolling forming machine. Pour a large amount of raw materials into the mixing feeder, and feed them continuously at a constant speed through the mixing feeder. The stirred raw materials are transported to the rolling forming machine through the feeding device, and the rolled finished product passes through the discharging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com