Special weatherproof moldproof functional master batch for wood/plastic composite material and preparation method thereof

A wood-plastic composite material and functional masterbatch technology, which is applied in the field of weather-resistant and mildew-proof functional masterbatch and its preparation, can solve the problems of short service life, poor weather resistance, easy to mold, etc., and achieves improved service life and no dust pollution , the effect of preventing the growth of mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

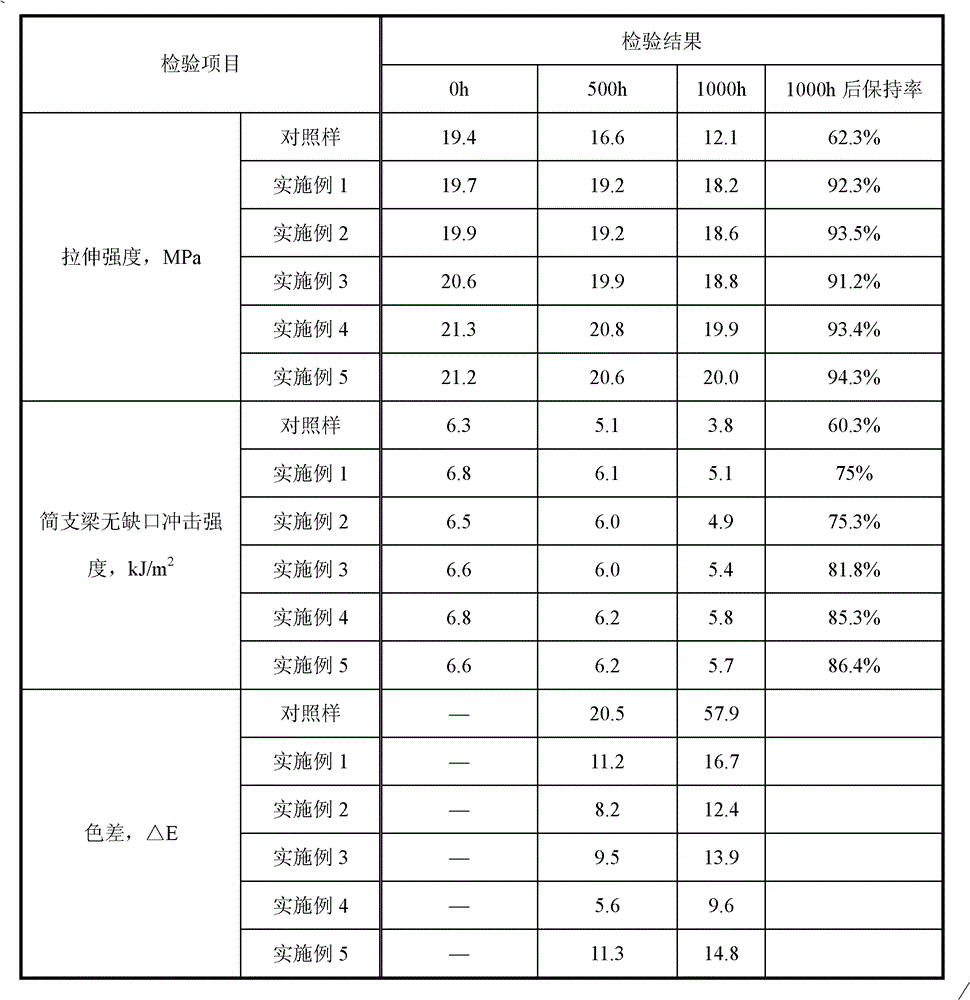

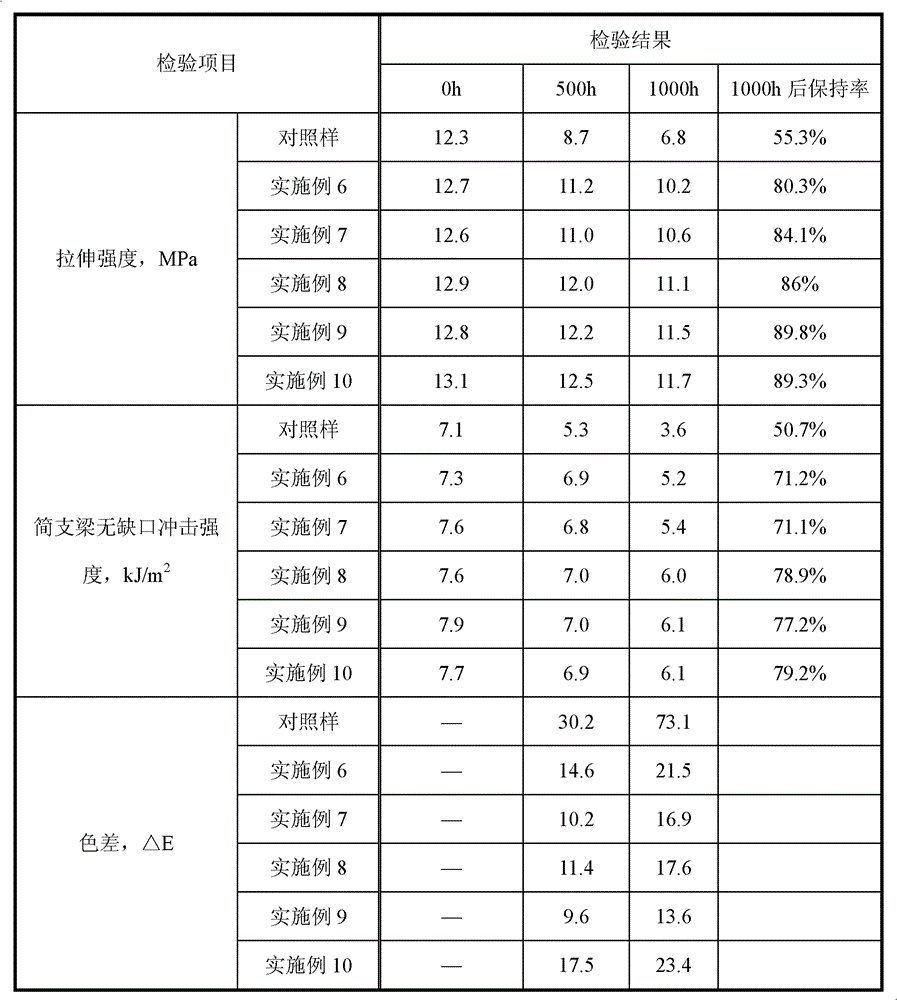

Examples

Embodiment 1

[0038] 1. First, add 40kg of carrier material polyethylene PE, 5kg of dispersant ethylene bis stearic acid amide and 5kg of polyethylene wax into a high-speed mixer at a speed of 500r / min, and stir at a high speed for 2min, then add light stabilizer Tinuvin36010kg, Add 15kg of acid absorbent ZnO, 3005kg of antioxidant, 10kg of fungicide DCOIT and 10kg of folpet into a high-speed mixer at the same time at a speed of 500 / min, and stir at a high speed for 3 minutes to obtain a mixture.

[0039] 2. Put the mixture into the twin-screw extruder, the temperature is 110℃~130℃, the screw speed is 200r / min, the mixture is extruded through the twin-screw extruder, cooled and granulated to obtain the special weatherproof and anti-corrosion material for wood-plastic composite materials. Mold functional masterbatch is about 100kg.

[0040] 3. Add the obtained functional masterbatch to the raw material of the polyethylene-based wood-plastic composite material at a mass percentage of 3%, and ...

Embodiment 2

[0042] 1. First, add 45kg of carrier material polyethylene PE, 3kg of dispersant ethylene bis stearic acid amide and 2kg of polyethylene wax into a high-speed mixer at a speed of 500r / min, stir at high speed for 1min, and then add 3608kg of light stabilizer Tinuvin , 10kg of acid absorbent ZnO, 3007kg of antioxidant, 15kg of fungicide DCOIT and 10kg of folpet, were added to a high-speed mixer at the same time, the speed was 500r / min, and high-speed stirring for 4min to obtain a mixture.

[0043] 2. Put the mixture into the twin-screw extruder, the temperature is 120℃~140℃, the screw speed is 240r / min, and the mixture is extruded through the twin-screw extruder, cooled and granulated to obtain a special weatherproof and anti-corrosion material for wood-plastic composite materials. Mold functional masterbatch is about 100kg.

[0044] 3. Add the obtained functional masterbatch to the raw material of polyethylene-based wood-plastic composite material at a mass percentage of 3%, an...

Embodiment 3

[0046] 1. First, add carrier material polyethylene PE 35kg, dispersant ethylene bis stearic acid amide 8kg and polyethylene wax 2kg into a high-speed mixer at a speed of 800r / min, high-speed stirring for 1min, and then light stabilizer Tinuvin 36010kg , acid absorbent ZnO 15kg, antioxidant 30010kg, fungicide DCOIT 10kg and folpet 10kg were added into a high-speed mixer at the same time, the speed was 800r / min, and high-speed stirring was carried out for 3 minutes to obtain a mixture.

[0047] 2. Put the mixture into the twin-screw extruder, the temperature is 130°C~150°C, the screw speed is 300r / min, the mixture is extruded through the twin-screw extruder, cooled and granulated to obtain a special weatherproof and anti-corrosion material for wood-plastic composite materials. Mold functional masterbatch is about 100kg.

[0048] 3. Add the obtained functional masterbatch to the raw material of polyethylene-based wood-plastic composite material at a mass percentage of 3%, and pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chromatic aberration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com