UVC-resistant ASA resin composition and preparation method thereof

A technology of ASA resin and composition, which is applied in the field of polymers, can solve the problems of easy warping and deformation, unstable shrinkage rate, and inability to cover radiation energy, and achieve the effects of reducing degradation, improving discoloration and physical property deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

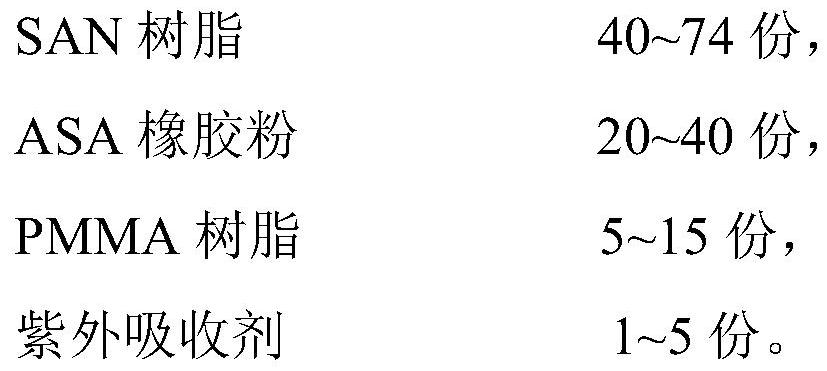

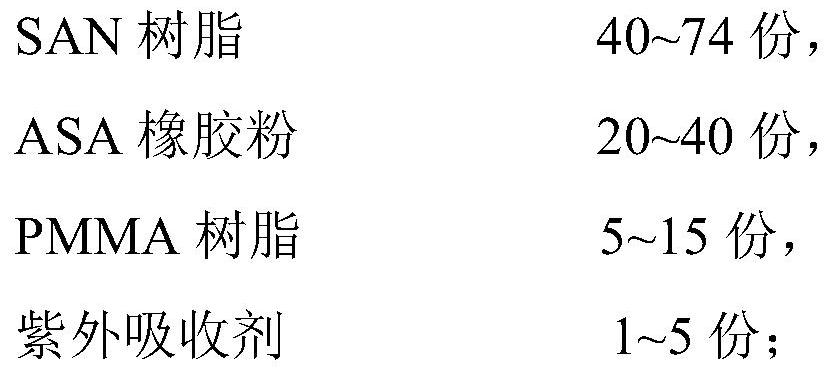

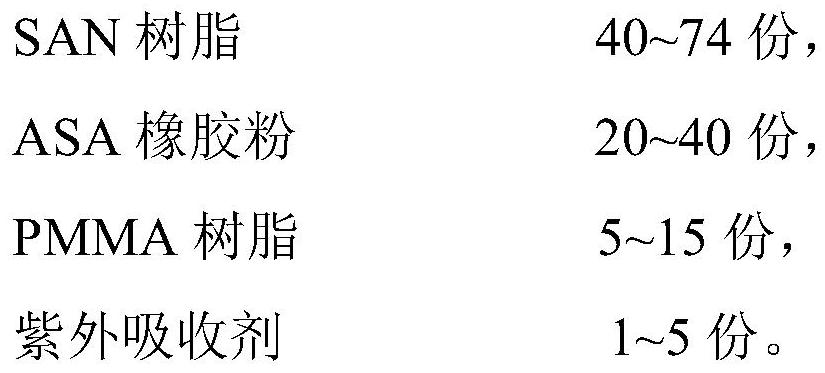

Method used

Image

Examples

Embodiment 1~8

[0026] A preparation method of UVC-resistant ASA resin, the method may further comprise the steps:

[0027] According to the weight percentage of the formulation ingredients in Table 1, the raw materials are added to the high-speed mixer and mixed thoroughly, and then placed in the screw machine, at an extrusion temperature of 180-250 ° C and a screw speed of 200-500 rpm. Melt extrusion, cooling and granulation to obtain the product.

[0028] Wherein, the material of Table 1 is as follows:

[0029] SAN: The weight-average molecular weight is 120,000, the acrylonitrile content is 32%, choose Kumho SAN 350

[0030] ASA: Choose Kumho XC-500

[0031] PMMA1: Melt index 1000g / 10min, test condition, 220°C, 10kg

[0032] PMMA2: Melt index 1500g / 10min, test condition, 220°C, 10kg

[0033] PMMA3: Melt index 2000g / 10min, test condition, 220°C, 10kg

[0034] UV absorber 1: tert-octylphenyl salicylate

[0035] UV absorber 2: 2-cyano-3-phenylethyl salicylate

[0036] UV absorber 3: 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com