Positive electrode, positive electrode slurry, preparation method and lithium ion battery

A positive electrode slurry and positive electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of improving cycle performance, improving slurry discoloration and slurry gelation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The present invention does not limit the preparation method of the positive electrode material. Exemplarily, the preparation method of the positive electrode material adopted in the embodiment of the present invention includes the following steps:

[0054] Preparation of active components of positive electrode material:

[0055] (1) Take 495.61g Li 2 CO 3 , 486.67g Fe(NO 3 ) 3 , 1000g (NH 4 ) 3 PO 4 , 840.20gMn (NO 3 ) 2 , 82.70g of sucrose, and 992.36g of water were mixed uniformly to obtain a slurry, and the slurry was spray-dried in a spray dryer.

[0056] (2) The spray-dried samples were placed in a tube furnace under nitrogen atmosphere, and the temperature was programmed to 500 °C for 12 h;

[0057] (3) Add 33.08g of sucrose after the first calcined sample is crushed, and roast it at 700℃ for 8h under nitrogen atmosphere, and the crushing is LiMn 0.7 Fe 0.3 PO 4 active ingredient.

[0058] It should be understood by those skilled in the art that the a...

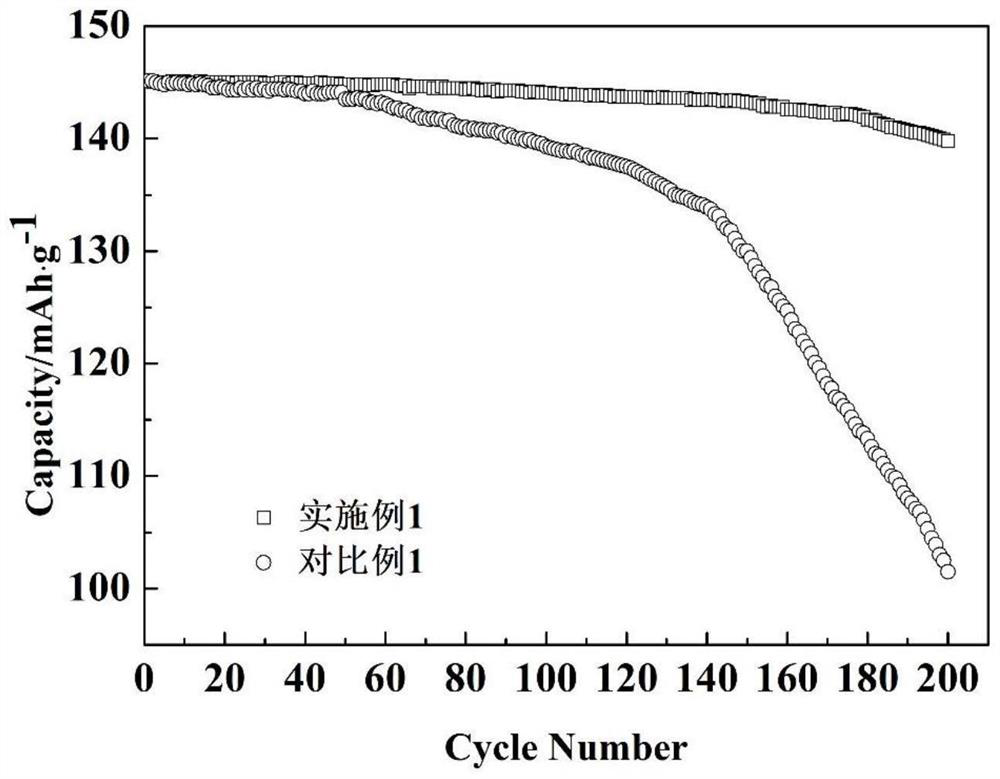

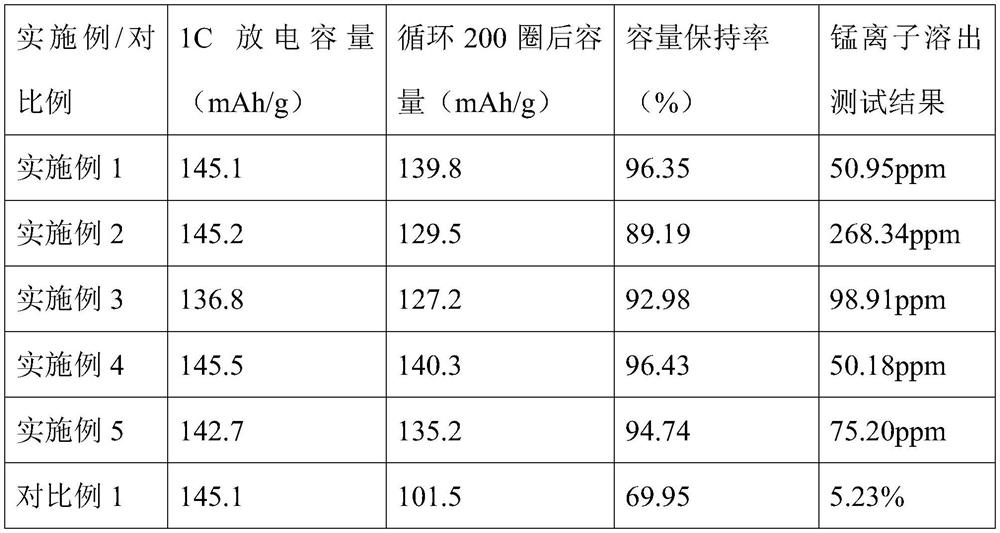

Embodiment 1

[0060] This embodiment provides a LiMn 0.7 Fe 0.3 PO 4 positive electrode, by using the LiMn 0.7 Fe 0.3 PO 4 The cycle performance of the battery prepared from the positive electrode is improved, the LiMn 0.7 Fe 0.3 PO 4 The positive electrode comprises a current collector and a positive electrode material layer disposed on one side surface of the current collector, a complexing agent is dispersed in the inside and the surface of the positive electrode material layer, the current collector is an aluminum foil, and the complexing agent is EDTA, with LiMn 0.7 Fe 0.3 PO 4 The mass is 100%, and the content of EDTA is 0.15%.

[0061] The LiMn 0.7 Fe 0.3 PO 4 The preparation method of the positive electrode comprises the following steps:

[0062] 800g positive active component LiMn 0.7 Fe 0.3 PO 4 , 1.20g of ethylenediaminetetraacetic acid (EDTA), 100g of conductive agent acetylene black, 100g of binder polyvinylidene fluoride (PVDF), added to 800g of N-methylpyrrol...

Embodiment 2

[0066] The difference between this example and Example 1 is that the amount of EDTA added is adjusted so that LiMn 0.7 Fe 0.3 PO 4 In the positive electrode, the content of EDTA was 0.01%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com