Quaternary ammonium salt type surfactant fracturing fluid

A technology of surfactant and quaternary ammonium salt, which is applied in the field of quaternary ammonium salt type viscoelastic surfactant fracturing fluid, can solve problems such as difficult to meet the effective development of oil and gas reservoirs, and achieve easy industrial production, mild reaction conditions, and a preparation method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

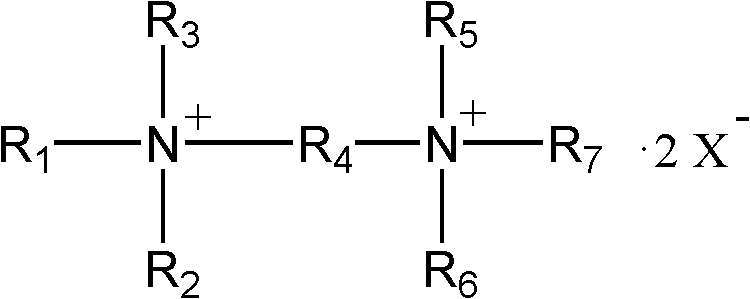

[0038] (1) Synthesis of diionic headgroup surfactants

[0039] Take 1 mol of 1,4-butanediamine, 2 mol of formic acid, and 2 mol of formaldehyde in a reaction kettle, react at 70°C for 8 hours, and cool to room temperature after the reaction. Next, 2 mol of octadecane chloride was added to the reaction kettle, and reacted at 80° C. for 8 hours to obtain a white paste product, numbered De-18-4.

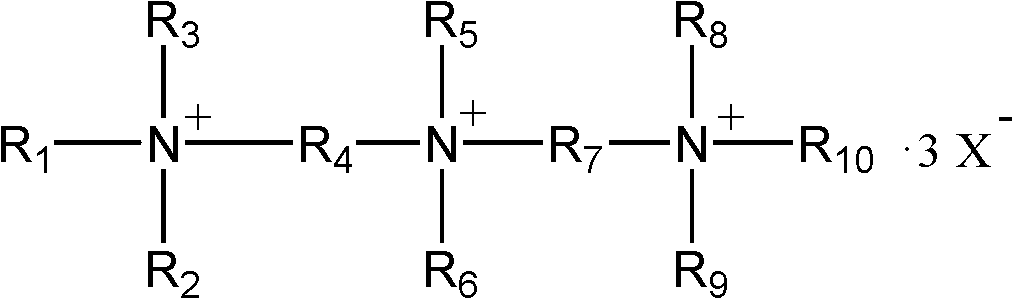

[0040] (2) Synthesis of triionic headgroup surfactants

[0041]Take 1 mol of dialkylenetriamine, 5 mol of formic acid, and 5 mol of formaldehyde in a reaction kettle, react at 70° C. for 8 hours, and cool to room temperature after the reaction. Next, 3 mol of dodecane chloride was added to the reaction kettle, and reacted at 80° C. for 8 hours to obtain a white paste product, numbered Tr-12-2.

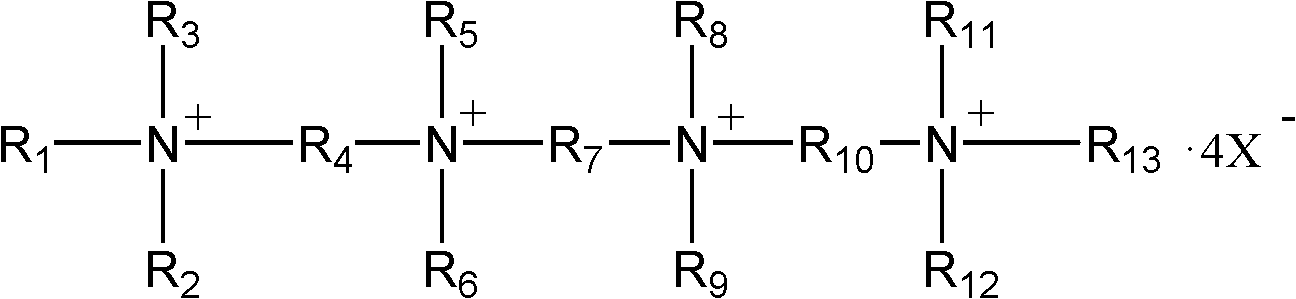

[0042] (3) Synthesis of tetraionic headgroup surfactants

[0043] Take 1 mol of trialkylenetetramine, 7 mol of formic acid, and 7 mol of formaldehyde in a reaction kettle, react at 70° C. for...

Embodiment 2

[0045] The high-temperature-resistant viscoelastic surfactant fracturing fluid is composed of: 4.5% De-18-4 surfactant, 0.5% ammonium chloride, 1% potassium chloride, 0.4% methyl Sodium benzenesulfonate and the balance of water.

Embodiment 3

[0047] The high temperature resistant viscoelastic surfactant fracturing fluid is composed by weight percentage: 3.5% Tr-14-2, 0.5% sodium chloride, 0.1% salicylic acid, 0.1% potassium benzenesulfonate, 0.1% ammonium benzenesulfonate and the balance water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com