Method for harvesting cultured spirulina

A harvesting method and technology of spirulina, which is applied in the field of harvesting cultured spirulina, can solve the problems of not being able to remove the medium components in time, affecting the continued growth of spirulina, and high density of algae in the culture pond, and achieve easy management and maintenance, large-scale Large, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

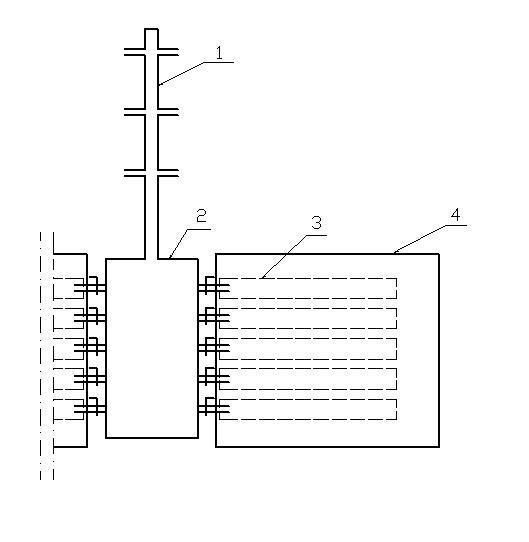

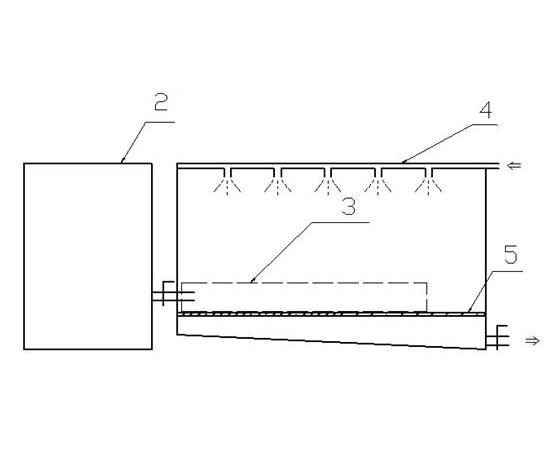

[0021] The present invention is composed of a pipe network device 1 , a split flow regulating device 2 , a filtration separation device 3 and a cleaning device 4 .

[0022] The pipe network device centralizes the cultured algae liquid in each culture pond to the diversion adjustment device in a self-flowing manner; the diversion adjustment device injects the algae liquid with a certain flow rate and flow into the filtration separation device and cleaning device to control and adjust the flow rate The amount of algae liquid in the filtration and separation device; the filtration and separation device uses a rice pocket filter to separate the algae mud from the liquid medium; the cleaning device washes and rinses the algae mud containing salt and high pH value with tap water to complete desalination and impurities .

[0023] 1) Pipe network device: The spirulina liquid in each culture pond passes through a closed pipe network and is gathered together for harvesting. Among them,...

Embodiment 2

[0029] The pipe network device 1 and the diversion regulating device 2 are the same as those in the first embodiment.

[0030] Filtration and separation device 3 is made of 360-mesh sieve silk, with a length of 15 meters and a diameter of 0.4 meters. Media separation.

[0031] The cleaning device 4 is the same as the first embodiment, and the algae mud containing salt and high pH value is rinsed with tap water to remove salt and impurities. After the rinsing is completed, open the water outlet valve at the bottom, pass the cleaned algae mud through the horizontal sieve bag to separate the algae mud from the clean cleaning water.

Embodiment 3

[0033] The pipe network device 1, the shunt adjustment device 2 and the filtration and separation device 3 are the same as the above two embodiments, first close the water outlet valve at the bottom of the cleaning device, raise the water level to be consistent with the height of the filtration and separation device 3; then open the water inlet, and carry out Rinse, and keep the water inlet and outlet consistent to maintain the water level; when filtration and separation are required, open the outlet valve at the bottom of the cleaning device to empty the water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com