Method for preparing nano silver solution by electrolysis

An electrolytic solution and nano-silver technology, which is applied in the field of preparation of nano-silver solution, can solve the problems that the properties of nano-silver are easily affected and nano-silver is difficult to preserve, and achieve the effects of wide application value, long stable time and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 nano silver solution

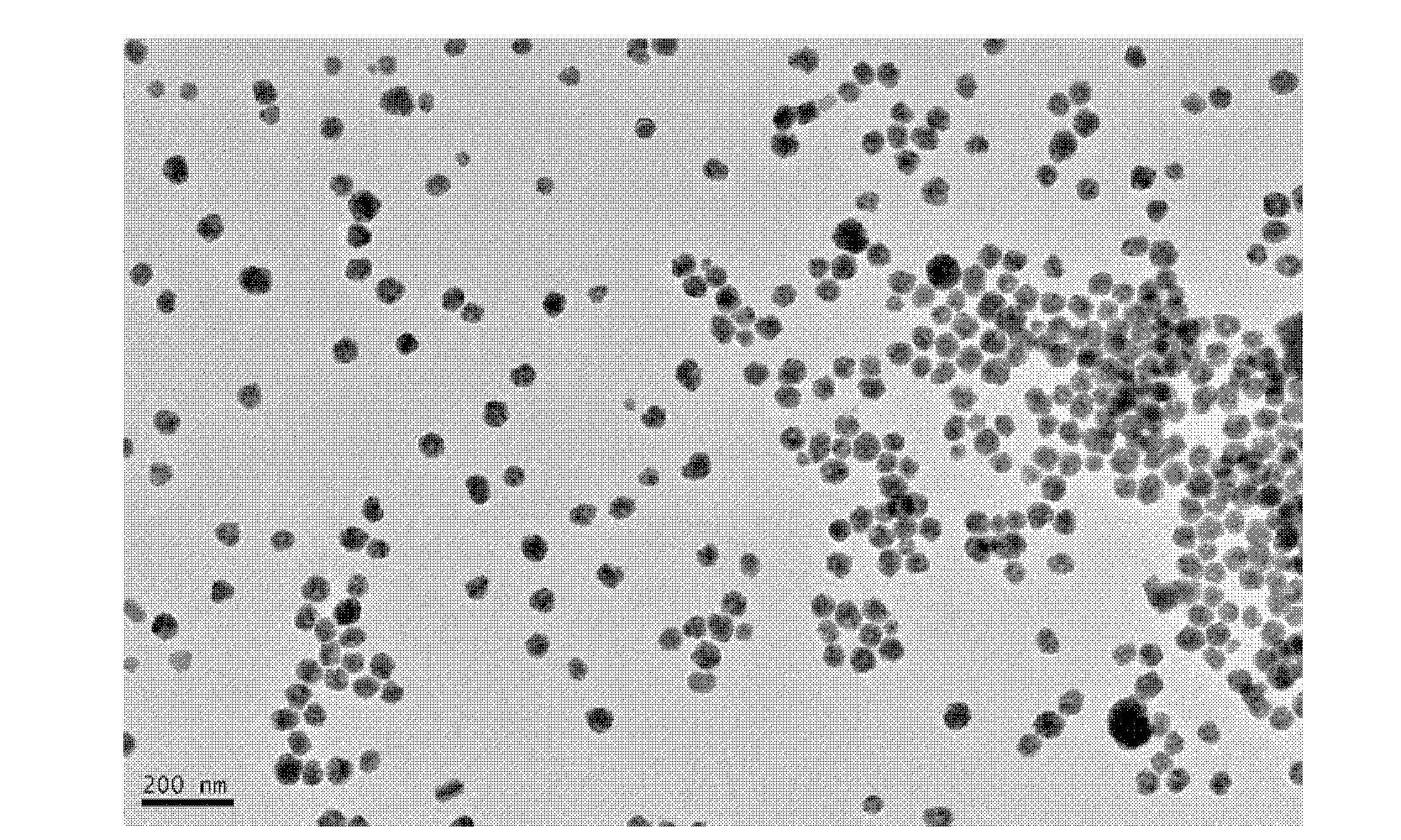

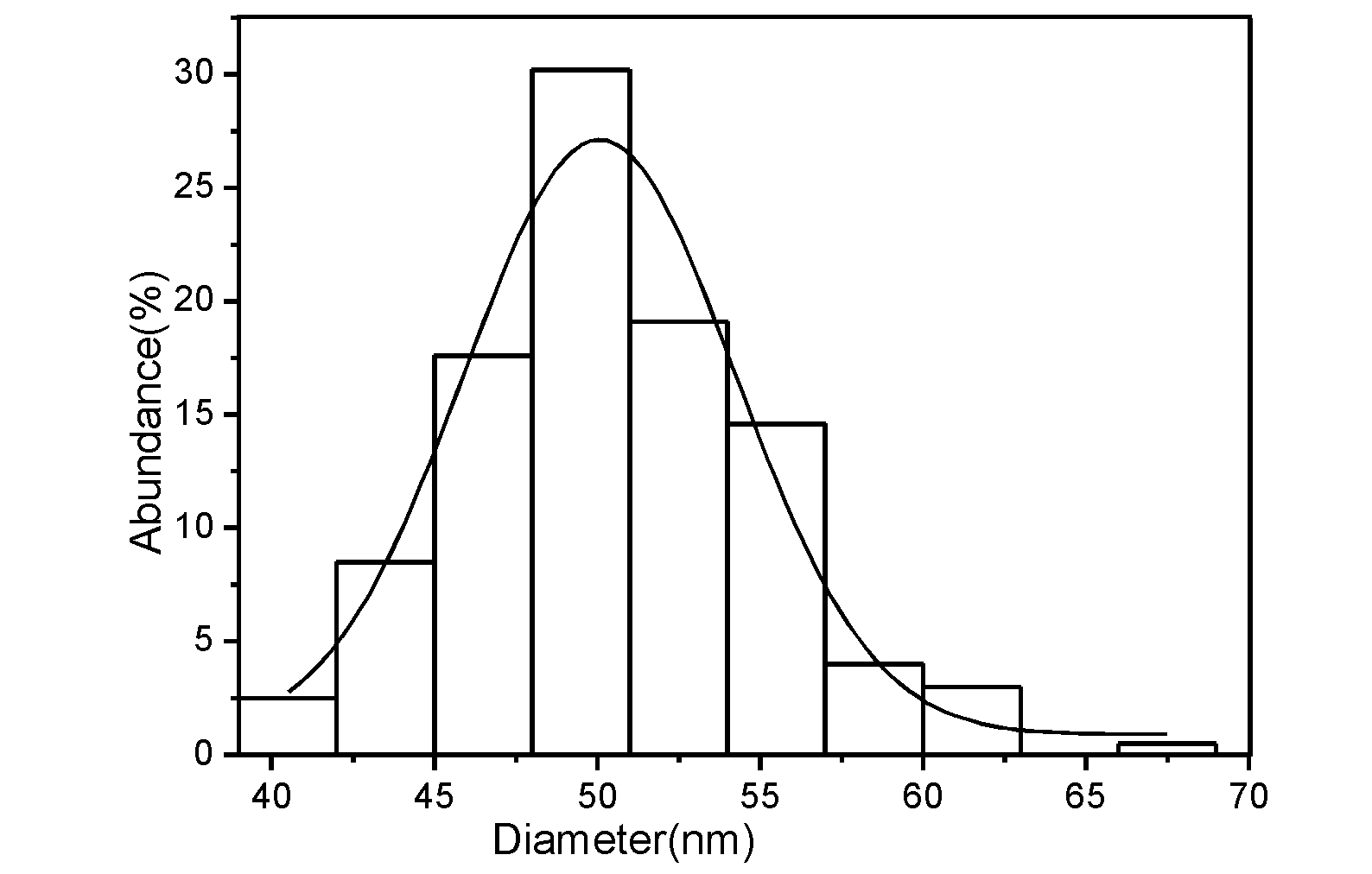

[0033] Use a silver needle with a diameter of 2mm and a length of 90mm as an electrode, add 200mL of water to a 250mL beaker, weigh 2g of polyvinyl alcohol and dissolve it in the added water under magnetic stirring in a water bath to form a colorless and transparent solution. After the alcohol was completely dissolved, the temperature of the water bath was fixed at 95°C. After the temperature is constant, add a polytetrafluoroethylene stopper with a silver needle electrode fixed on the beaker, keep the distance between the electrodes at 2cm, and conduct electricity for 3min at a DC voltage of 25V to obtain a nano-silver solution. determined, as figure 1 with figure 2 Shown, the average particle diameter of nano-silver solution is 50nm.

Embodiment 2

[0034] The preparation of embodiment 2 nano-silver solution

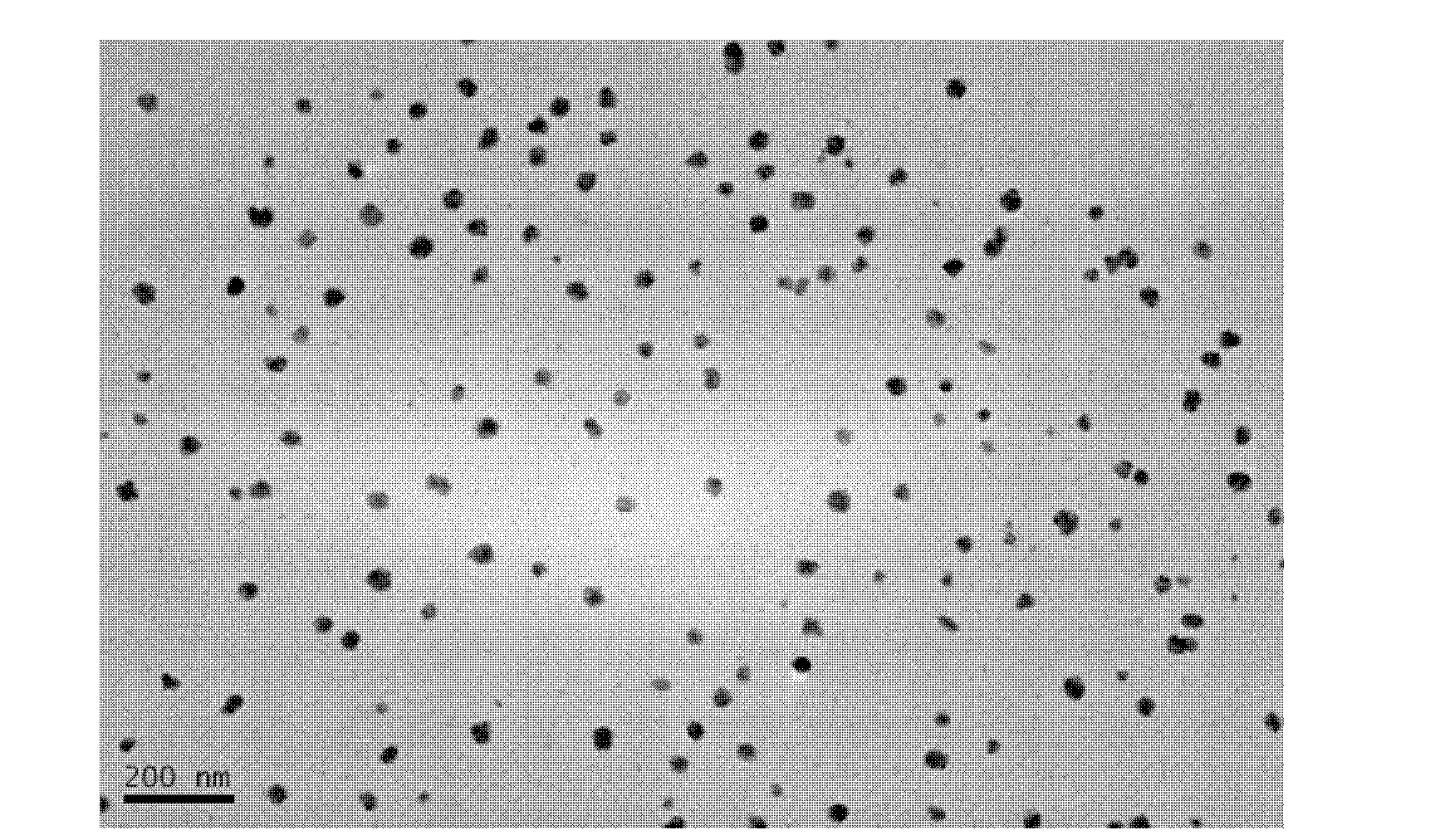

[0035] Use a silver needle with a diameter of 2mm and a length of 90mm as an electrode, add 200mL of water to a 250mL beaker, weigh 2g of polyvinyl alcohol and dissolve it in the added water under magnetic stirring in a water bath to form a colorless and transparent solution. After the alcohol was completely dissolved, the temperature of the water bath was fixed at 75°C. After the temperature is constant, add a polytetrafluoroethylene stopper with a silver needle electrode fixed on the beaker, keep the distance between the electrodes at 2 cm, and energize for 4 minutes at a DC voltage of 25V to obtain a nano-silver solution. determined, as image 3 with Figure 4 Shown, the average particle diameter of nano-silver solution is 35nm.

Embodiment 3

[0036] The preparation of embodiment 3 nano-silver solution

[0037] Use a silver needle with a diameter of 2mm and a length of 90mm as an electrode, add 200mL of water to a 250mL beaker, weigh 2g of polyvinyl alcohol and dissolve it in the added water under magnetic stirring in a water bath to form a colorless and transparent solution. After the alcohol was completely dissolved, the temperature of the water bath was fixed at 50 °C. After the temperature is constant, add a polytetrafluoroethylene stopper with silver needle electrodes fixed on the beaker, keep the distance between the electrodes at 2cm, and energize for 5min at a DC voltage of 25V to obtain a nano-silver solution. determined, as Figure 5 with Image 6 Shown, the average particle diameter of nano-silver solution is 30nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com