Weathering preventing and reinforcing method and structure of mudstone side slope of waste residue storage yard

A technology for strengthening the structure and preventing weathering. It is used in basic structure engineering, excavation, construction, etc., and can solve the problems of mudstone layered landslides and threats to the safety of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

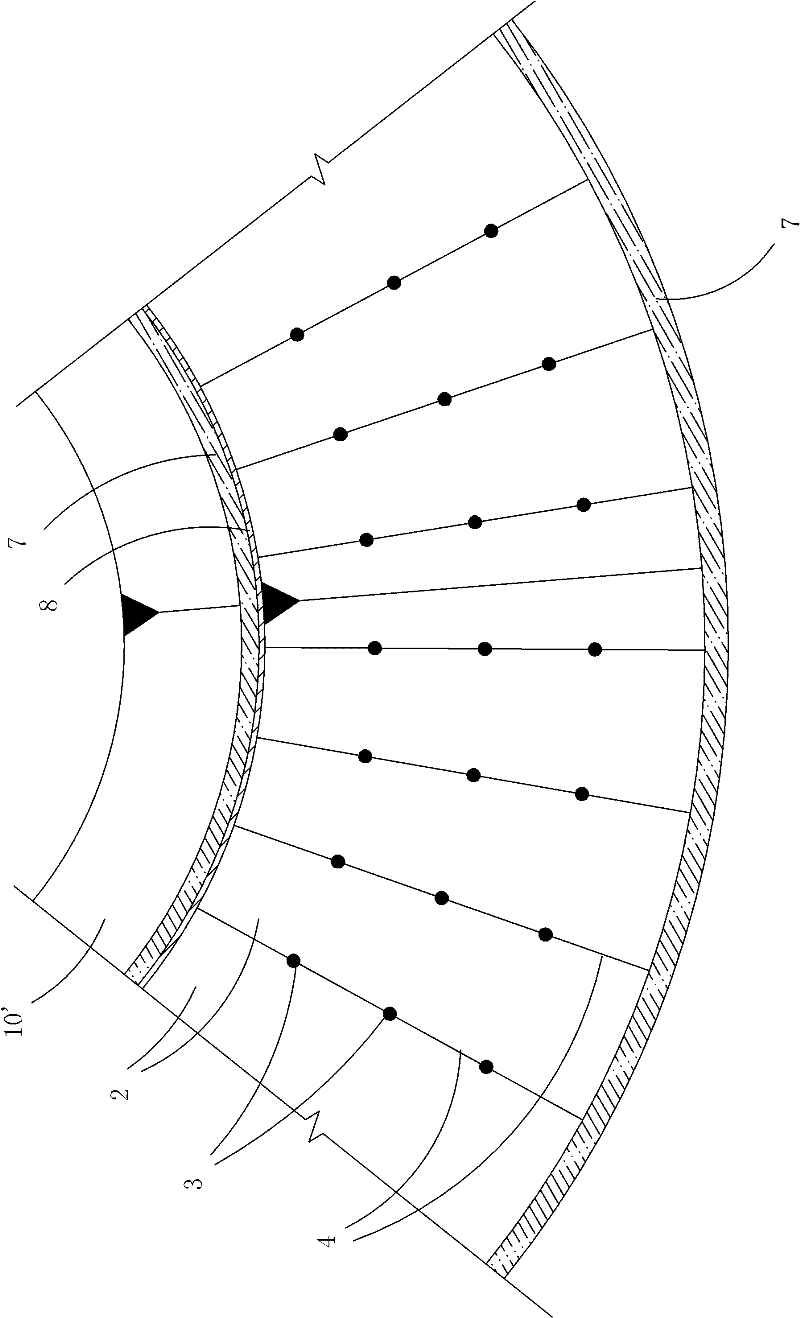

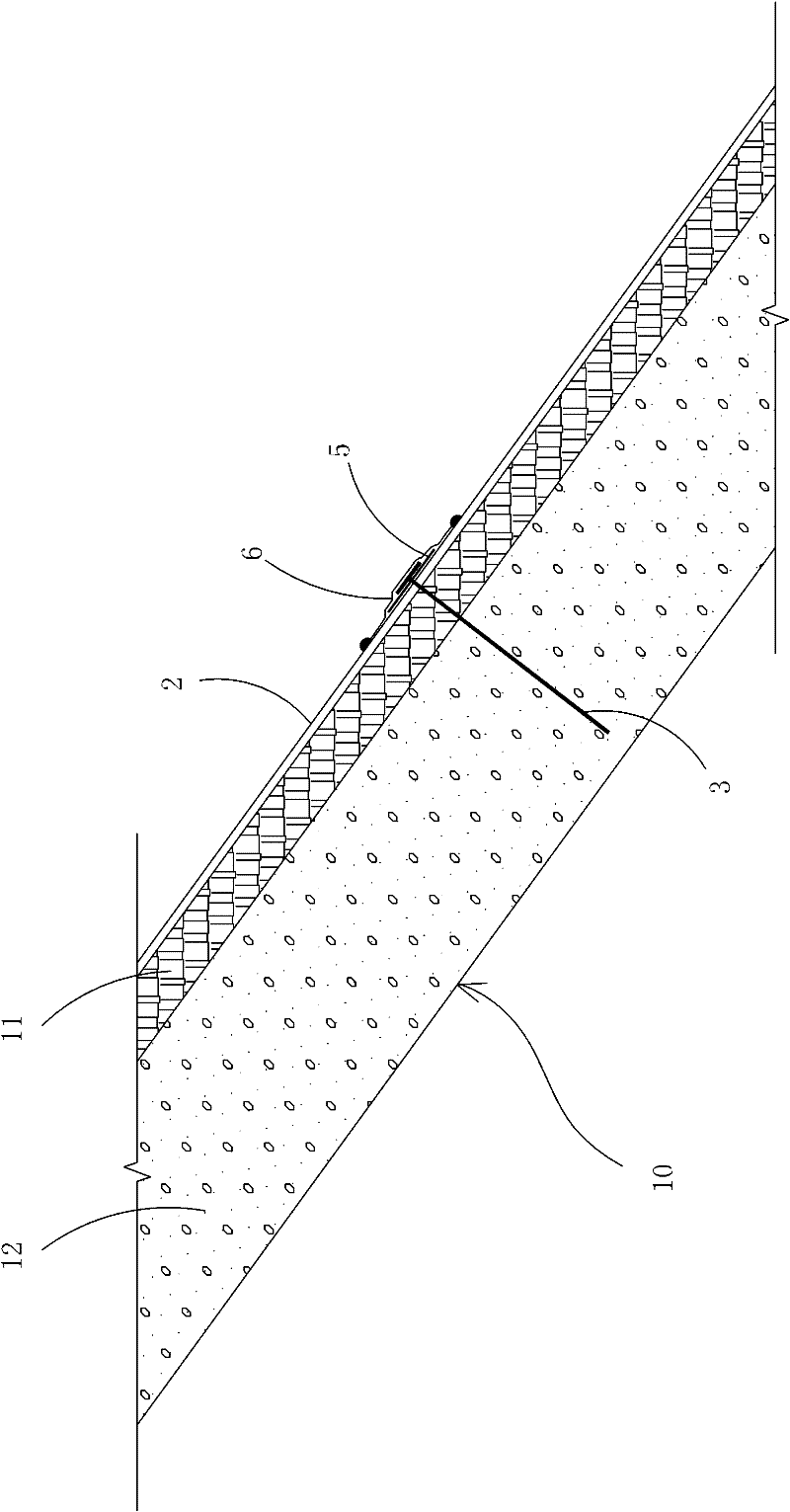

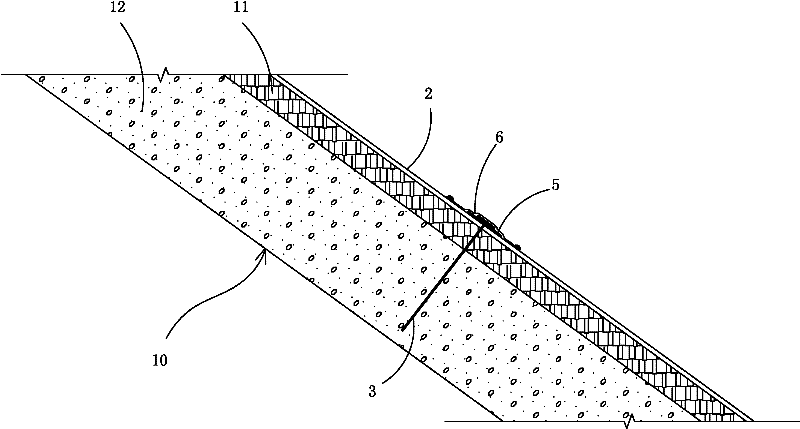

[0019] Such as figure 1 , figure 2 As shown, the mudstone slope surface of the waste dump is a strongly weathered mudstone layer 11 , and below the strengthened mudstone layer is a slightly weathered mudstone layer 12 . There are upper and lower two platforms 7 on the side slope, between the two platforms is a mudstone side slope 10 that has been cleared of vegetation and trimmed, and the upper side slope of the upper platform is an uncleaned hillside 10'. On the mudstone slope 10 that has removed vegetation and repaired, be covered with the thick thin layer polyethylene film 2 (purchase commercially available polyethylene film product) of 0.5-0.75mm that has added carbon black, described polyethylene film is made of many Strip-shaped polyethylene films are welded, each polyethylene film is arranged longitudinally, and the upper end of each polyethylene film 2 is anchored in the anchoring groove 8 at the lower edge of the upper platform. A plurality of soil nails 3 are long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com