Method for locating underground non-cable test system

A test system and positioning method technology, applied in the field of positioning, can solve problems such as unusable, difficult positioning of the downhole cableless test system, complex borehole trajectory, etc., and achieve the effect of simple operation, low hardware cost and accurate calculation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following combination Figure 1~Figure 7 A preferred embodiment of the present invention is described in detail in order to better illustrate the method features and functions of the present invention.

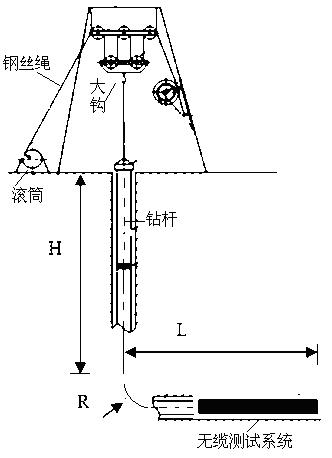

[0029] figure 1 It is a schematic diagram of the downhole cableless test system being lifted in a horizontal well. The downhole cableless test system involved in the figure is a general term for various downhole test devices, not a specific one. The initial position of its movement starts from the end of the well bottom, and its movement The power comes from the hook and wire rope traction for lifting the drill pipe, and the hoisting speed of the hook is determined by the rotation speed of the wire rope drum on the ground. The figure shows a horizontal well as an example, the vertical drilling distance H , deflection radius R , Horizontal drilling distance L Wait.

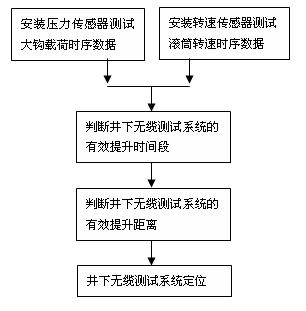

[0030] figure 2 It is a flow chart of the positioning steps of the downhole cableless testing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com