A preparation method of a flexible, hybridized and dye sensitized solar cell

A dye sensitization, solar cell technology, applied in photosensitive devices, circuits, capacitors, etc., can solve problems such as unfavorable production and popularization, increase battery weight, increase production cost, etc., and achieve narrow absorption range, simple production process, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Disperse P25 in a mixed solution of ethanol and tert-butanol (mass ratio 1:2), magnetically stir for 3 hours, and ball mill for 15 hours to prepare slurry A with a mass percentage of 10%.

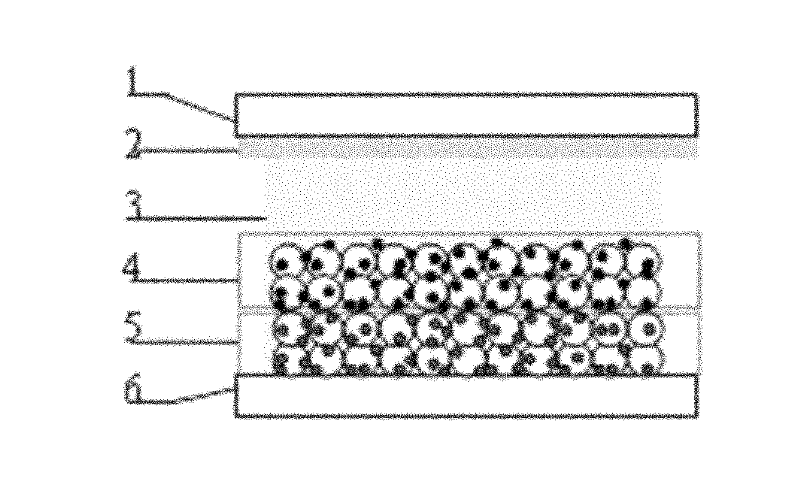

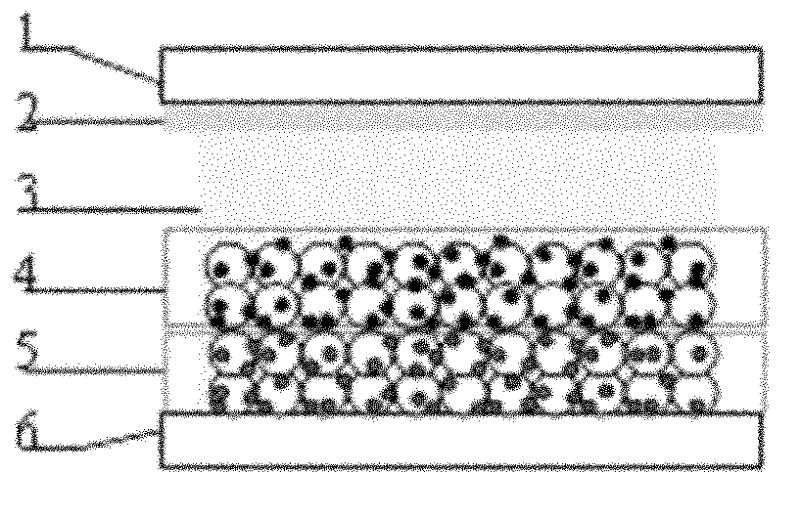

[0032] (2) Using a flexible conductive film (such as ITO / PEN) as the base material, the base thickness is 200 μm, the visible light transmittance is 80%, and the surface resistance is 15Ω / cm 2 .

[0033] (3) Clean the substrate with detergent to remove stains, rinse it with deionized water, then ultrasonically clean it in deionized water, absolute ethanol, and acetone for 10 minutes, and dry it with nitrogen.

[0034] (4) Use 3M adhesive tape to stick the substrate on a smooth and flat desktop, and use the scraper method to evenly coat the slurry A on the substrate with a thickness of 5-10 μm. After drying naturally at room temperature, heat treatment at a low temperature of 150°C for 2 hours, and cold isostatic pressing with a pressure of 300MPa.

[0035] (5) Immerse the above...

Embodiment 2

[0041] (1) Uniformly disperse 10nm, 38nm, 100nm TiO2 nanopowders in a certain proportion in tert-butanol, stir magnetically for 3 hours, and ball mill for 15 hours to prepare slurry B with a mass percentage of 10%.

[0042] (2) Using a flexible conductive film (ITO / PEN) as the base material, the base thickness is 200 μm, the visible light transmittance is 80%, and the surface resistance is 15Ω / cm 2 .

[0043] (3) Clean the substrate with detergent to remove stains, rinse it with deionized water, then ultrasonically clean it in deionized water, absolute ethanol, and acetone for 10 minutes, and dry it with nitrogen.

[0044] (4) Use 3M adhesive tape to stick the substrate on a smooth and flat desktop, and use the scraper method to evenly coat the slurry B on the substrate with a thickness of 5-10 μm. After natural drying at room temperature, heat treatment at 150°C for 2 hours, cold isostatic pressing with a pressure of 300MPa, and laser annealing with a KrF excimer laser.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com