Pickled oyster mushrooms and preparation method thereof

A technology of oyster mushroom and kimchi, applied in the field of oyster mushroom kimchi products and its preparation, achieving the effects of stable quality, simple process, and rich variety of kimchi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: Pleurotus ostreatus kimchi products are made from flat mushrooms, salt, white granulated sugar, water and leavening agent, wherein, described flat mushrooms, table salt, white granulated sugar and water are by weight: 600 parts of flat mushrooms, 36 parts of table salt, 36 parts of white granulated sugar, 1200 parts of water, the leavening agent is old pickle water, and its addition is calculated in parts by weight: old pickle water: oyster mushroom=1:10, and its preparation step is: oyster mushroom cleaning After cleaning, blanching in boiling water for 30 seconds, immediately cooling to room temperature in cold boiled water, draining the water, putting it in a kimchi jar, adding 3% pepper and ginger according to the weight ratio of oyster mushrooms, and 2% Garlic, 0.5% star anise and Chinese prickly ash, add the cooled pickling solution of 2 times the weight of oyster mushrooms in the pickle altar, the pickle solution is an aqueous solution containing 3% ...

Embodiment 2

[0025] Embodiment 2: leavening agent is lactobacillus pentosus, and its addition reaches 10 by the thalline content in the solution 7 -10 8 In terms of cfu / mL, specifically, the Lactobacillus pentosus purchased from Chr. , the activation temperature is 37°C. After the strain is activated, place it in a low-speed centrifuge and centrifuge at a speed of 4500r / min for 25 minutes, remove the white precipitate in the lower layer, and wash it with sterilized water for 2 to 3 times to obtain the starter Lactobacillus pentosus. Other is with embodiment 1, obtains flat mushroom kimchi products.

Embodiment 3

[0026] Embodiment 3: leavening agent is standard bacterial strain Lactobacillus plantarum, and its addition reaches 10 by the thalline content in the solution 7 -10 8 Calculated in cfu / mL, specifically, the standard strain Lactobacillus plantarum purchased from the Microbial Culture Collection Center of the Chinese Academy of Sciences was activated and centrifuged according to the following steps: inoculated in liquid MRS medium at a volume ratio of 1:100 for activation, activated The time is 12 hours, and the activation temperature is 30°C. After the strain is activated, put it in a low-speed centrifuge and centrifuge at 4500r / min for 25 minutes, remove the white precipitate in the lower layer, wash it with sterilized water for 2 to 3 times, and then get the starter standard strain Lactobacillus plantarum for use , other are with embodiment 1, obtain flat mushroom kimchi products.

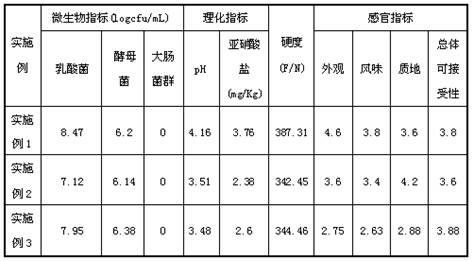

[0027] The quality analysis of the flat mushroom kimchi products that above-mentioned embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com