Lead-in type gas distribution method for dielectric barrier discharge activated carbon regeneration reactor

A dielectric barrier discharge and dielectric barrier technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of low utilization efficiency of added gas, difficulty in uniform distribution, and full contact with objects difficult to discharge treatment, etc., to achieve structural Simple, easy to make, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

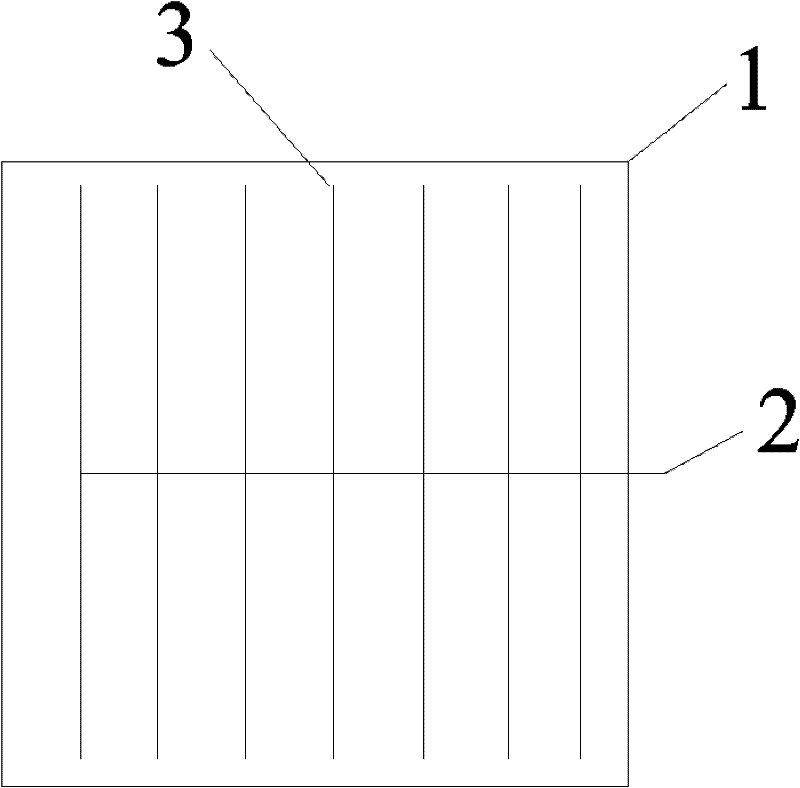

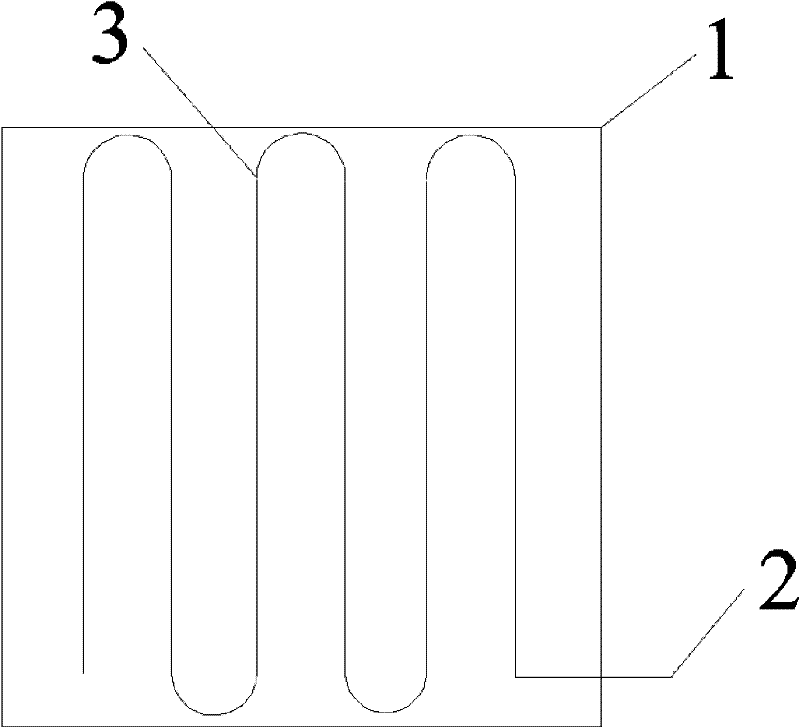

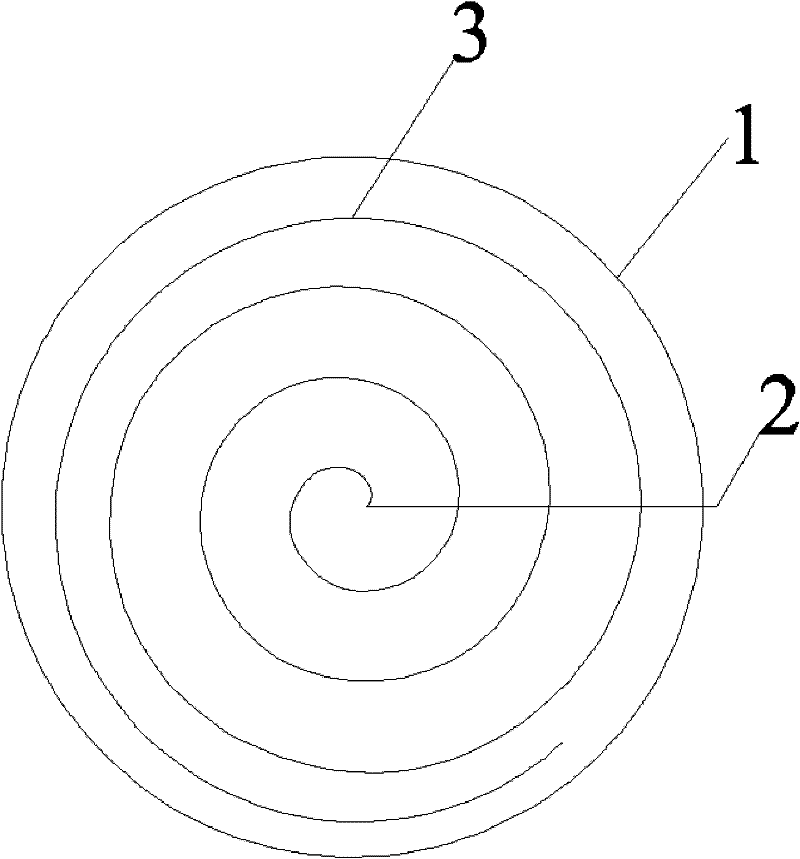

[0019] The imported gas distribution method of the dielectric barrier discharge activated carbon regeneration reactor is to place the PVC material air guide pipe in the activated carbon packed bed of the dielectric barrier reactor to provide the reaction gas source for the reactor. The length, width and height of the activated carbon packed bed are 400mm ×400mm×16mm insulating plastic, activated carbon filled bed. The arrangement of the air duct is as follows figure 1 As shown in the prickly shape, the diameter of the air guide tube is 5mm, and there are gas outlet micropores all over the body, and the diameter of the micropores is 0.5mm; the gas enters from the inlet through the air pump, and seeps out from each micropore along the air guide tube, uniformly Distributed in the discharge space of the reactor, it provides th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com