Coated abrasive tool and manufacturing method thereof

A technology for coating abrasive tools and manufacturing methods, which is applied in the direction of manufacturing tools, abrasives, grinding devices, etc., can solve the problems of unstable grinding performance, unsatisfactory wear resistance and durability, and achieve stable grinding performance. , good durability and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

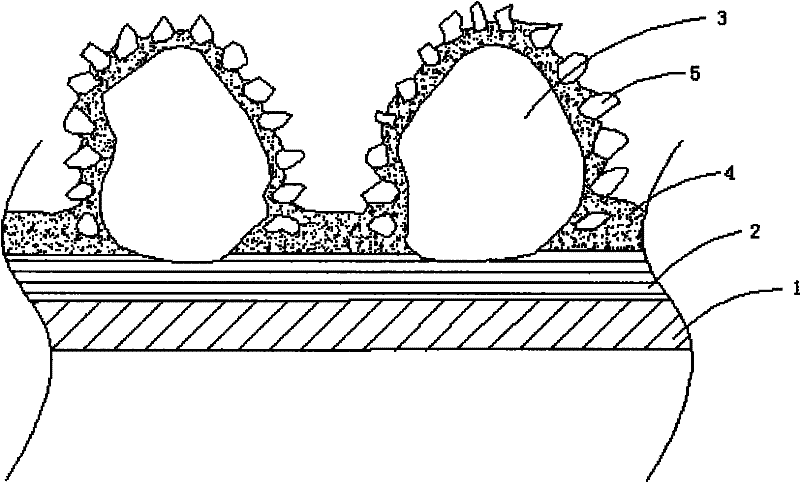

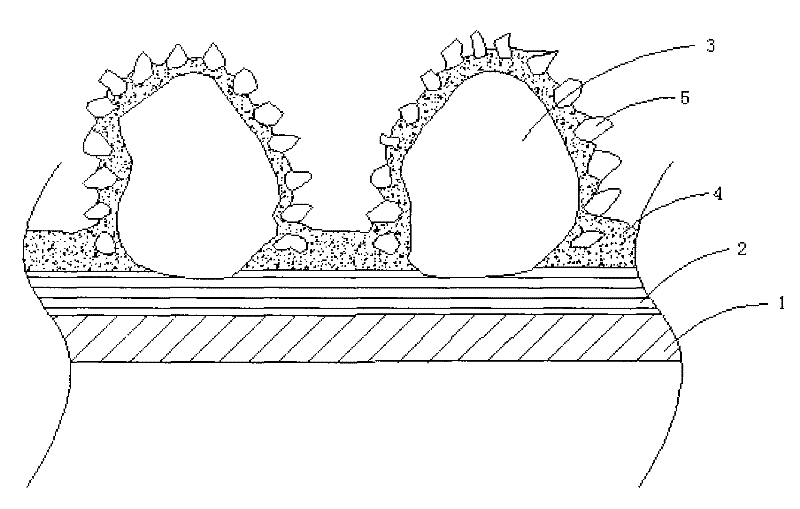

[0021] Embodiment: a kind of coated abrasive tool is made of substrate 1, primer layer 2, glue layer 4, several cork grains 3 and several abrasive grains 5, and the primer layer is bonded on the base Surface, the size adhesive layer is bonded to the upper surface of the primer layer, all the cork particles are not bonded between the primer layer and the size layer, and all the abrasive grains are bonded to the The compounded layer, wherein, a part of the abrasive grains is covered in the compounded layer, and another part of the abrasive grains exposes part of the volume in the compounded layer.

[0022] Cork, commonly known as cork and cork, is the outer skin product of tree species with a well-developed cork layer, and the surface protection tissue after the stems and roots grow thicker. Cork particle size is divided into three particle sizes, which can be specified according to customer requirements.

[0023] The size of abrasive grains can be made according to customer ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap