Preparation method of low-calorie functional fat

A technology of structural fat and low heat, applied in the field of preparation of low heat structural fat, can solve the problem of low absorption and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

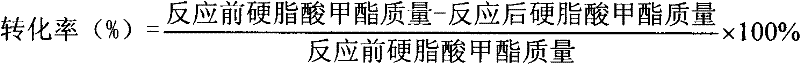

[0026] Accurately weigh 1.5118g of triglyceride butyrate and 2.9850g of methyl stearate in a 50mL round-bottomed flask, heat-melt and mix well, then add 0.3597g (8% based on substrate) Lipozyme RMIM, and immediately dissolve at 60°C Constant temperature water bath reduced pressure (0.01MP) rotation (80r / min) reaction 5h. Immediately after the reaction is finished, it is rapidly cooled with running water, dissolved in diethyl ether as a solvent, removed by high-speed centrifugation, and the solvent is removed by rotary evaporation to obtain a low-heat structured lipid.

[0027] It was detected that the conversion rate of methyl stearate was 63.9%, the content of LCSL in the product was 96.5% (wherein, the content of SSL was 68.0%, the content of LLS was 28.5%), and the content of LLL was 2.8%.

Embodiment 2

[0029] Accurately weigh 1.5118g of triglyceride butyrate and 2.9850g of methyl stearate in a 50mL round-bottomed flask, after hot melting and mixing, add 0.4497g (10% based on substrate) Lipozyme RMIM, immediately at 60°C Constant temperature water bath reduced pressure (0.01MP) rotation (80r / min) reaction 5h. Immediately after the reaction is finished, it is rapidly cooled with running water, dissolved in diethyl ether as a solvent, removed by high-speed centrifugation, and the solvent is removed by rotary evaporation to obtain a low-heat structured lipid.

[0030] It was detected that the conversion rate of methyl stearate was 91.5%, the LCSL content in the product was 94.6% (wherein, the SSL content was 48.6%, the LLS content was 46.0%), and the LLL content was 5.1%.

Embodiment 3

[0032] Accurately weigh 1.5118g of triglyceride butyrate and 2.9850g of methyl stearate in a 50mL round-bottomed flask, heat-melt and mix well, then add 0.3597g (8% based on substrate) Lipozyme RMIM, and immediately dissolve at 80°C Constant temperature water bath reduced pressure (0.01MP) rotation (80r / min) reaction 5h. Immediately after the reaction is finished, it is rapidly cooled with running water, dissolved in diethyl ether as a solvent, removed by high-speed centrifugation, and the solvent is removed by rotary evaporation to obtain a low-heat structured lipid.

[0033] It was detected that the conversion rate of methyl stearate was 60.9%, the yield of LCSL in the product was 89.4% (wherein, the content of SSL was 54.2%, the content of LLS was 35.2%), and the content of LLL was 9.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com