Pretreatment method before molybdenum copper carrier electroplating

A pretreatment and carrier technology, applied in the field of metal surface treatment, can solve the problems of poor bonding force, large environmental impact, complex oxide film, etc., and achieve the effect of simple method and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

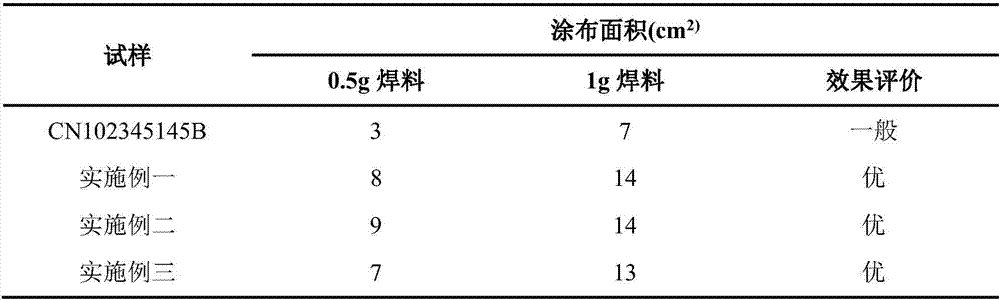

Examples

Embodiment 1

[0035] A pretreatment method before electroplating of a molybdenum copper carrier, is characterized in that, comprises the following steps:

[0036] (1) degreasing;

[0037] Soak the molybdenum-copper carrier in a degreasing powder solution with a concentration of 50g / L and ultrasonically clean it for 10 minutes, then soak it in acetone and ultrasonically clean it for 10 minutes to remove the oil on the surface of the molybdenum-copper carrier;

[0038] (2) Alkali washing and pickling;

[0039] Place the molybdenum-copper carrier in a sodium hydroxide solution with a concentration of 150g / L, boil for 10 minutes, take it out and wash it with a large amount of pure water; then place it in a hydrochloric acid solution with a concentration of 250ml / L, and boil for 5 minutes. After taking it out, wash it with plenty of pure water;

[0040] (3) Membrane removal activation;

[0041] Place the molybdenum-copper carrier in FeCl with a concentration of 180g / L 3 Remove the film in th...

Embodiment 2

[0045] A pretreatment method before electroplating of a molybdenum copper carrier, is characterized in that, comprises the following steps:

[0046] (1) degreasing;

[0047] Soak the molybdenum-copper carrier in a degreasing powder solution with a concentration of 70g / L and ultrasonically clean it for 10 minutes, then soak it in acetone and ultrasonically clean it for 12 minutes to remove the oil on the surface of the molybdenum-copper carrier;

[0048] (2) Alkali washing and pickling;

[0049] Place the molybdenum-copper carrier in a sodium hydroxide solution with a concentration of 200g / L, boil for 10 minutes, take it out and wash it with a large amount of pure water; then place it in a hydrochloric acid solution with a concentration of 280ml / L, and boil for 5 minutes. After taking it out, wash it with plenty of pure water;

[0050] (3) Membrane removal activation;

[0051] Place the molybdenum-copper carrier in FeCl with a concentration of 200g / L 3 Remove the film in the ...

Embodiment 3

[0055] A pretreatment method before electroplating of a molybdenum copper carrier, is characterized in that, comprises the following steps:

[0056] (1) degreasing;

[0057] Soak the molybdenum-copper carrier in a degreasing powder solution with a concentration of 50-80g / L and ultrasonically clean it for 10 minutes, then soak it in acetone and ultrasonically clean it for 10-15 minutes to remove the oil on the surface of the molybdenum-copper carrier;

[0058] (2) Alkali washing and pickling;

[0059] Place the molybdenum-copper carrier in a sodium hydroxide solution with a concentration of 150-250g / L, boil it for 10 minutes, take it out and wash it with a large amount of pure water; then place it in a hydrochloric acid solution with a concentration of 250-300ml / L, and boil it Keep it for 5 minutes, take it out and wash it with plenty of pure water;

[0060] (3) Membrane removal activation;

[0061] Place the molybdenum-copper carrier in FeCl with a concentration of 180-230g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com