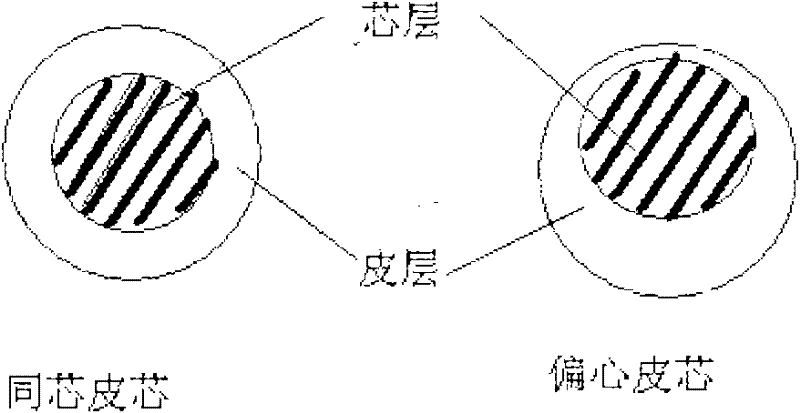

Biodegradable two-component low-melting point composite fiber

A composite fiber, biodegradable technology, applied in the direction of conjugated synthetic polymer man-made filaments, etc., can solve the problem of non-woven fabrics being non-biodegradable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

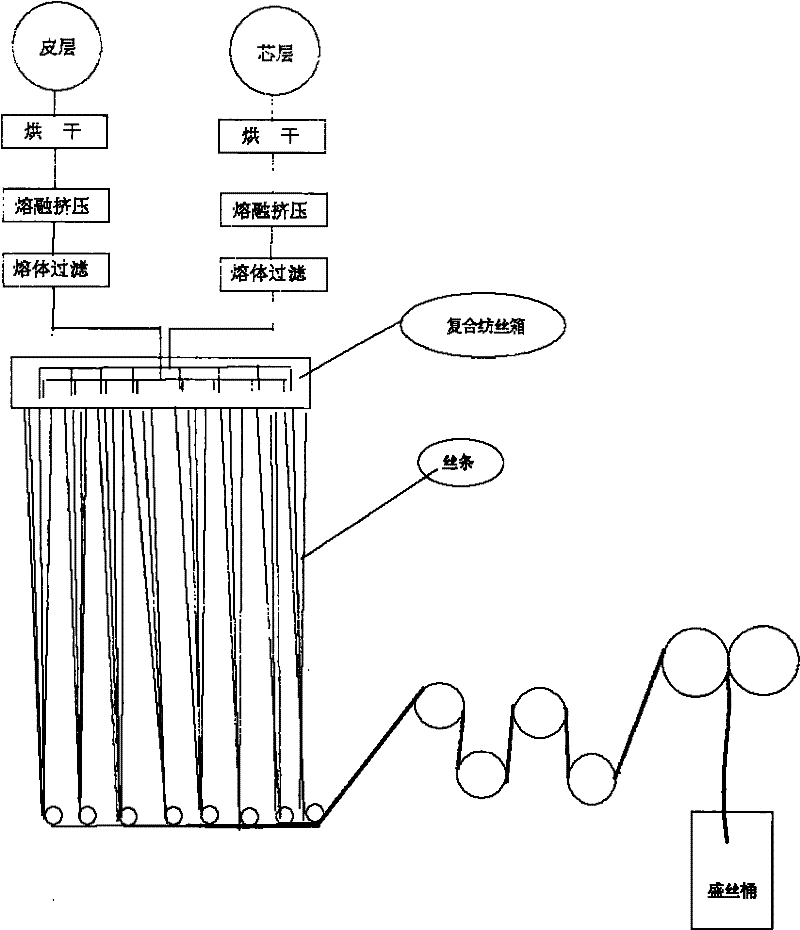

[0082] Example 1: 2D*38mm PBS35 / PLA65 two-component skin-core composite short fiber

[0083] refer to figure 2 Shown, the polybutylene succinate (PBS) / polylactic acid (PLA) sheath-core composite staple fiber production method that patent example 1 of the present invention makes is as follows:

[0084] Raw materials used:

[0085] (1) Polybutylene succinate (PBS) Origin: Haier Chemical Engineering Plastics National Engineering Research Center Co., Ltd.

[0086] Grade Q320 melt index MFI 25-30

[0087] Melting point 113(℃) crystallinity 20-35(%)

[0088] Glass transition temperature -46(°C) Heat distortion temperature 70(°C)

[0089] (2) Polylactic acid (PLA) Origin: Ningbo Global Plastic Products Co., Ltd.

[0090] Grade A312 Intrinsic viscosity IV(dl / g)0.2~10

[0091] Glass transition temperature > 60°C, melting point > 170°C,

[0092] Optical purity > 97% Viscosity average molecular weight 100000-800000

[0093] Monomer content < 0.5%

[0094] The above two raw mate...

example 2

[0105] Mix 31% of the above-mentioned short fibers with 69% viscose fibers (1.5D*38mm), comb to form a fiber web, and then pass through a pair of hot pressing rollers. The temperature of the hot pressing roll is 175-185°C, the fibers are melted, and the fibers are bonded together to form a biodegradable hot-rolled non-woven fabric. The weight of the non-woven fabric is 18GSM, and the product is used for the surface material of female sanitary napkins. Example 2 1.5D*6mm modified PBS / PLA two-component sheath-core composite short fiber

[0106] For the PBS particles in Example 1, CoPBS was added. CoPBS is made from PBS by grafting maleic anhydride. PBS, CoPBS, and polylactic acid PLA are vacuum-dried separately, and the moisture content of the raw materials used is less than 50PPM. The skin-to-core ratio was 35:65, and the cortical PBS contained 7.5% CoPBS.

[0107] The above skin / core two raw materials are dried using separate drum dryers. The following process is basicall...

example 3

[0124] Example 3 1.5D*6MM modified PBS35 / PLA65 25% 65 good

[0125] Fluff pulp 75%

[0126] Comparative sample 1 2D*38MM PE / PP 100% 17 Poor

[0127] Comparative sample 1 2D*4MM PE / PP 36% 80 Poor

[0128] Fluff pulp 75%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com