Discharge lamp

A discharge lamp and discharge vessel technology, applied in the manufacture of discharge lamps, gas discharge lamps, and discharge tubes/lamps, etc., can solve the problems of blocking the emitter, destroying the strength of the electrode, and easily deforming the electrode, and achieves stable diffusion and stability. The effect of electrode strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

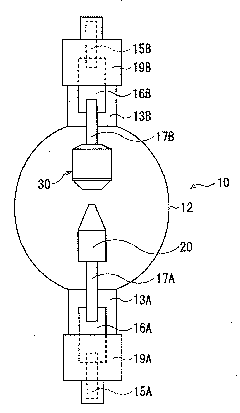

[0043]figure 1 It is a schematic cross-sectional view of the short-arc discharge lamp of the first embodiment.

[0044] The short-arc discharge lamp 10 has a transparent quartz glass arc tube 12, and inside the arc tube 12, a cathode 20 and an anode 30 are arranged to face each other with a predetermined interval therebetween. On both sides of the arc tube 12 , sealing tubes 13A and 13B made of quartz glass are provided continuously with the arc tube 12 and integrally formed. In the arc tube 12, rare gases such as tribute and argon are sealed.

[0045] Conductive electrode support rods 17A, 17B that support the cathode 20 and the anode 30 are arranged inside the sealed tubes 13A, 13B. Electrode support bars 17A, 17B are connected to conductive lead bars 15A, 15B via metal foils 16A, 16B, respectively. Sealing tubes 13A, 13B are welded to metal foils 16A, 16B, respect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com