Magnetic connection module and network connector having same

A magnetic connection and Ethernet technology, which is applied to the parts, connection, and fixed connection of the connection device, can solve the problems of the pad 11 being separated from the PCB1, the connection reliability is reduced, and the unfavorable mechanized production, so as to reduce the defect rate and connection. High reliability and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

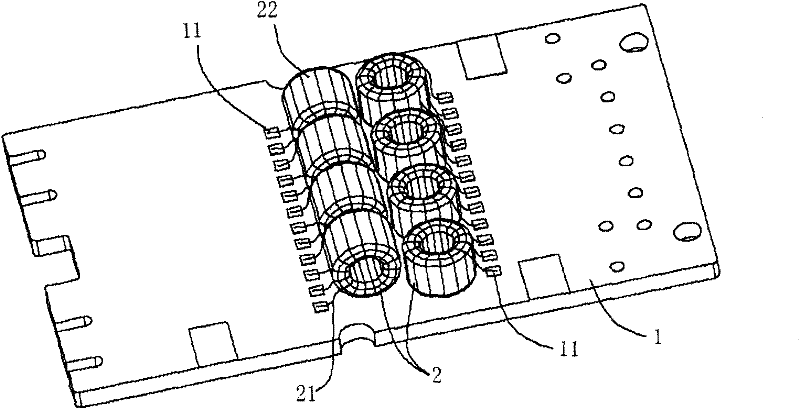

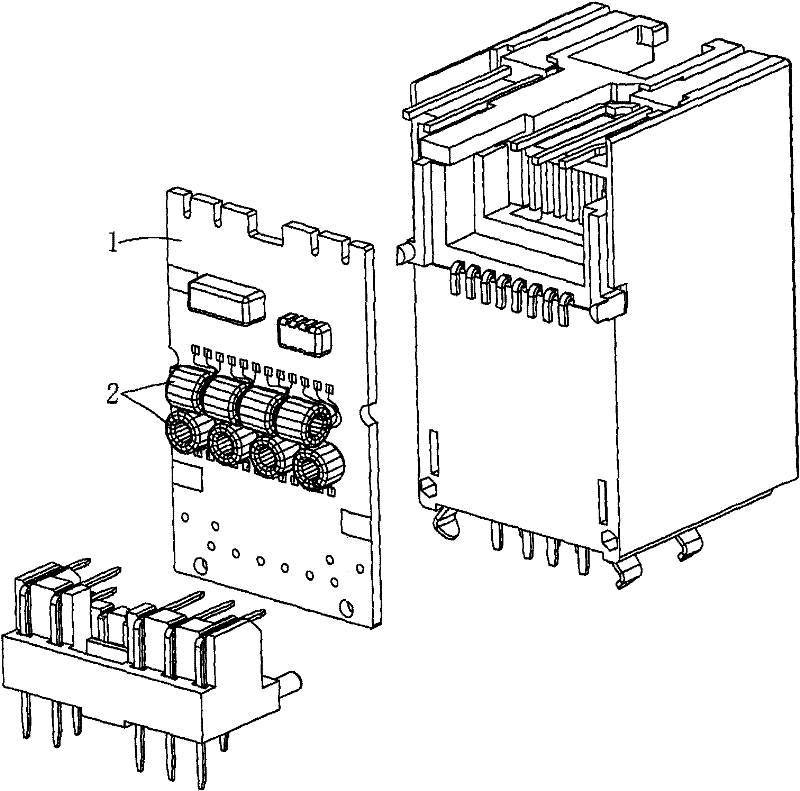

[0047] See Figure 3-9 , The first specific embodiment of the present invention provides a magnetic connection module suitable for automatic spot welding and a network connector using the magnetic connection module. First, see Figure 3-7 , a magnetic connection module suitable for automatic spot welding, which is applied in an Ethernet connection device to transmit network signals.

[0048] According to the first specific embodiment of the present invention, such as Figure 3-7As shown, the magnetic connection module includes a printed circuit board (PCB) 3 and a soldering assembly 7 mounted on the printed circuit board 3 . The welding assembly 7 includes a plastic inner seat 5 , a magnetic coil 6 and an adapter terminal 4 . Among them, the plastic inner seat 5 is arranged on the printed circuit board 3, and several magnetic coils 6 with paint leather wires 61 are arranged in the plastic inner seat 5, and several transfer terminals 4 further include paint leather wires 61 ...

no. 2 Embodiment

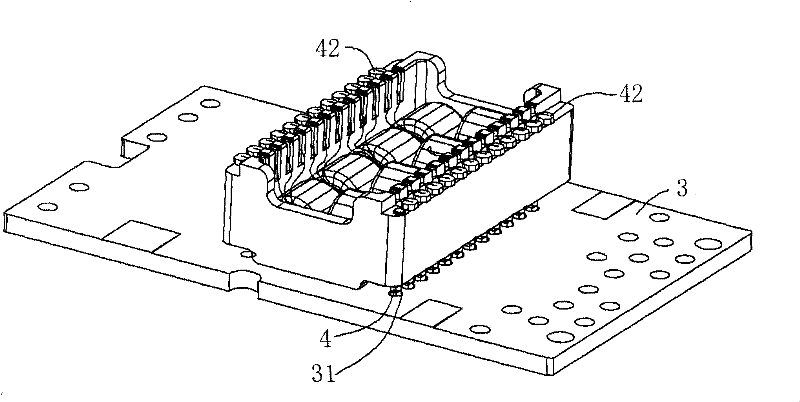

[0054] According to the present invention, a plurality of soldered assemblies 7, 7' may be mounted on the printed circuit board 3. In the second specific embodiment provided by the present invention, as Figure 10 As shown, the difference from the first specific embodiment is that a plurality of soldering assemblies 7, 7' can be mounted on the printed circuit board 3, and other specific structures of the magnetic connection module are the same as those described in the first specific embodiment above. or similar. Therefore, in this specific embodiment, only the structure of mounting multiple soldering assemblies 7, 7' on the printed circuit board 3 and the network connector with this type of magnetic connection module will be described in detail, and other structures will not be repeated.

[0055] According to the second specific embodiment of the present invention, such as Figure 10 As shown, a plurality of soldering assemblies 7, 7' at least include: at least one first so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com