Gunwale welding operating shed for laying submarine pipelines

A subsea pipeline and operation technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of restricting the development of subsea pipeline construction technology, high construction cost, poor climatic conditions, etc., and achieve good promotion and application prospects. , The effect of reducing construction costs and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

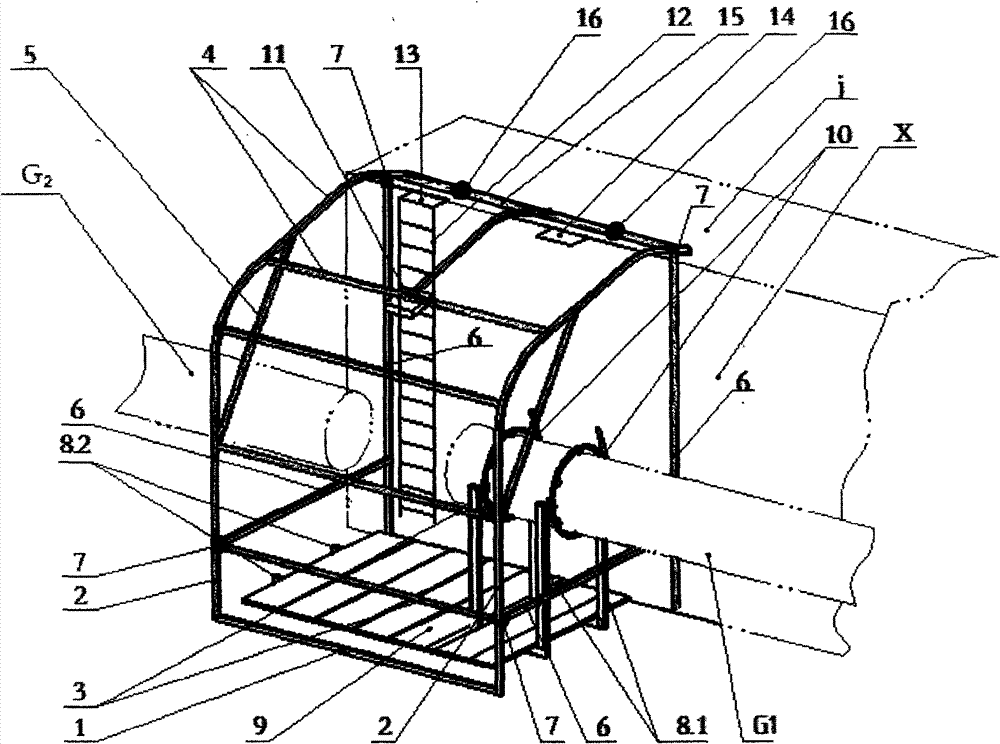

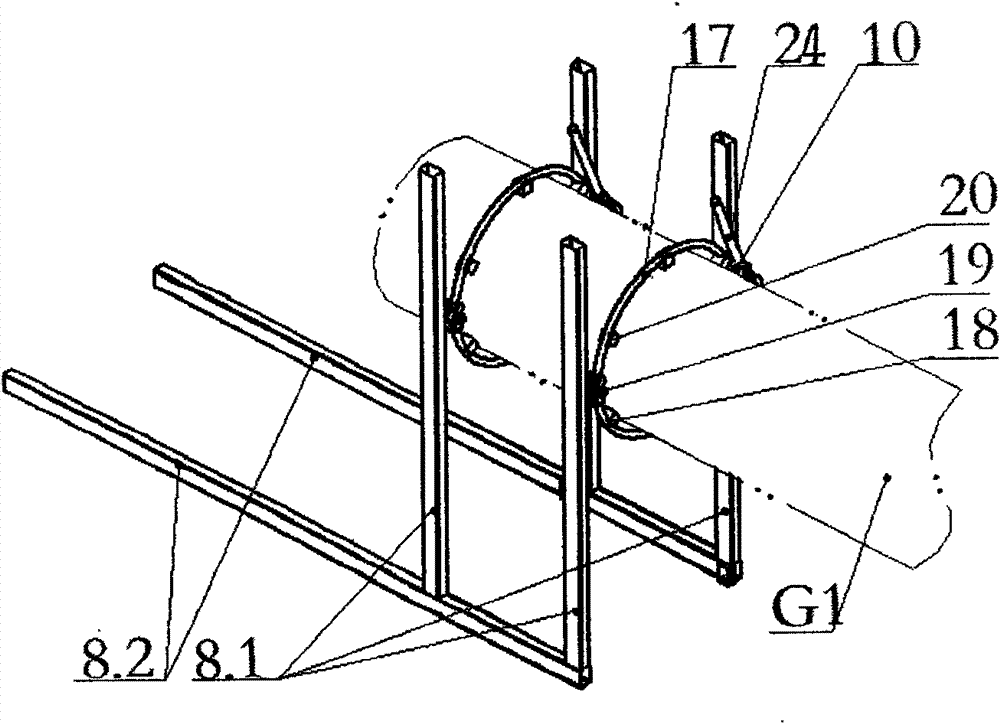

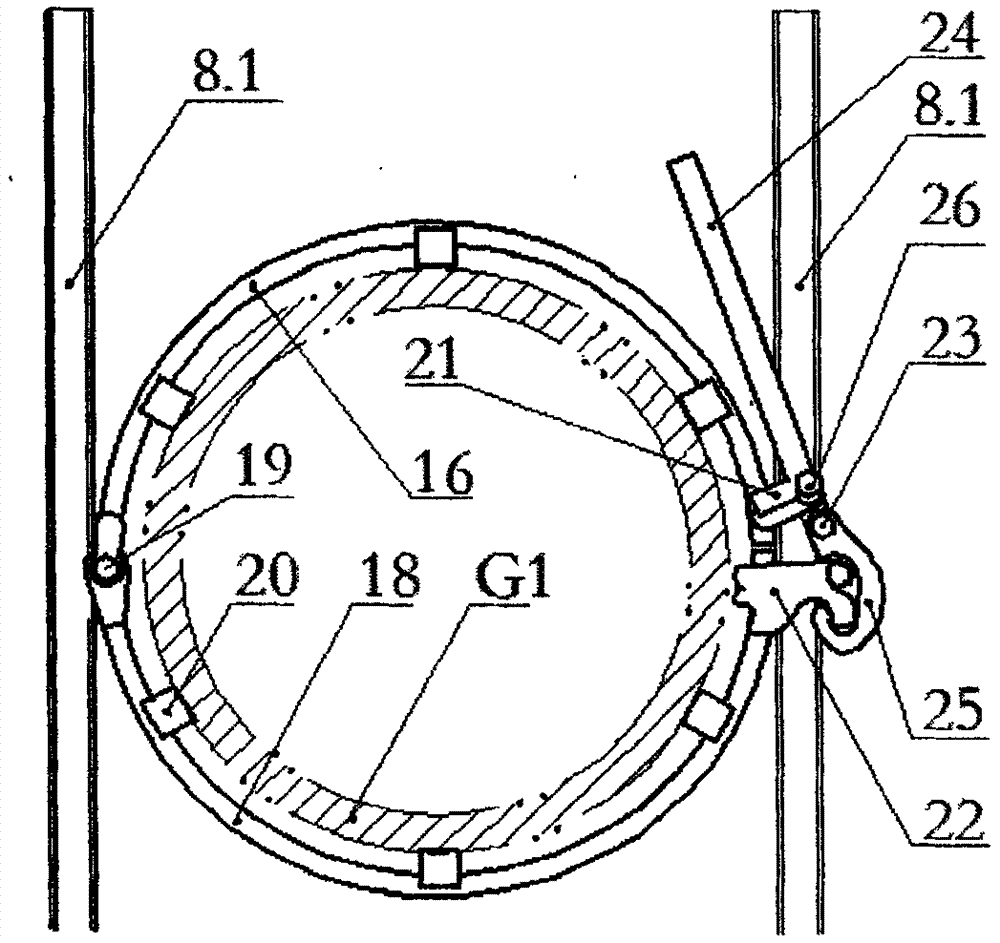

[0018] An embodiment is illustrated in conjunction with the accompanying drawings:

[0019] In the accompanying drawings, 1 is the bottom frame, 2 is the vertical frame, 3 is the horizontal frame, 4 is the top frame, 5 is the oblique frame, 6 is the detachable frame, 7 is the frame connecting bolt, 8. 1 is the vertical support, 8. 2 1 is the horizontal bracket, 9 is the floor, 10 is the fixture, 11 is the exhaust fan, 12 is the ladder, 13 is the entrance and exit, 14 is the observation window, 15 is the rotating shaft of the shed body, 16 is the magnet, 17 is the upper snap ring, 18 is the lower snap ring Ring, 19 is a hinge shaft, 20 is a spacer, 21 is a fixed block, 22 is a lower hook, 23 is a rotating shaft, 24 is a handle, 25 is an upper hook, and 26 is a fixed pin. G 1 is the right pipe, G 2 is the port pipe, X is the gunwale, and J is the deck.

[0020] Depend on figure 1 As shown, the submarine pipeline laying side welding operation shed, including shed body, supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com