Driving device

A technology of a driving device and a switching device, which is applied to the arrangement of multiple prime movers of a power device, a pneumatic power device, and a general power device, and can solve problems such as high mechanical consumption and limited possibility of internal combustion engine operation, and achieve The effect of small mechanical consumption and small structural space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

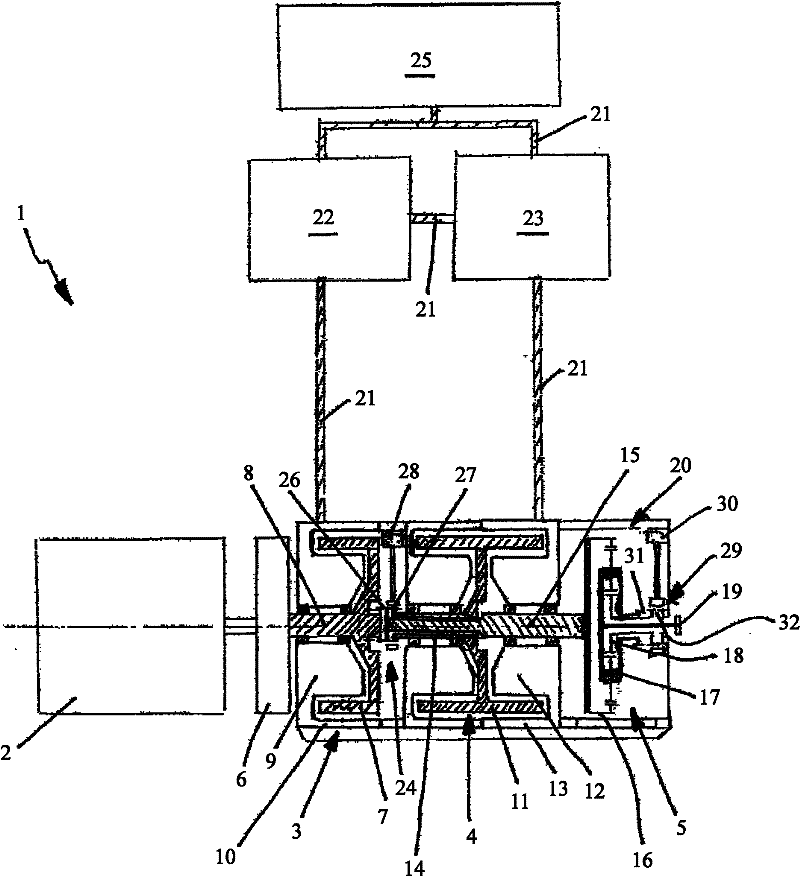

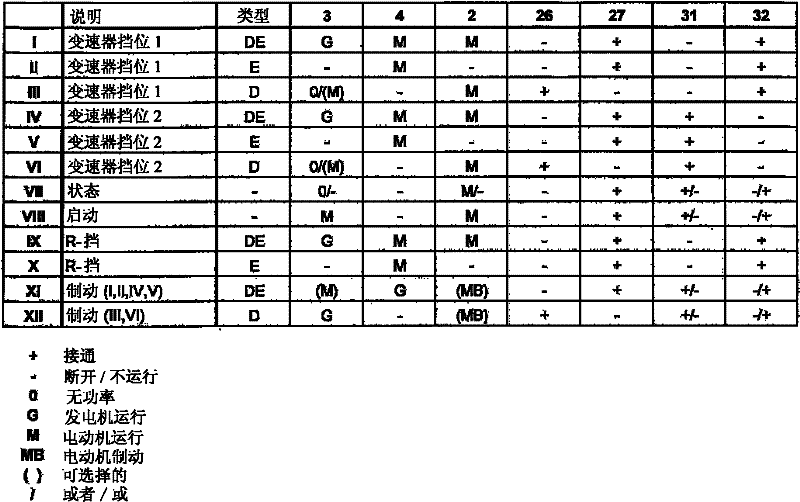

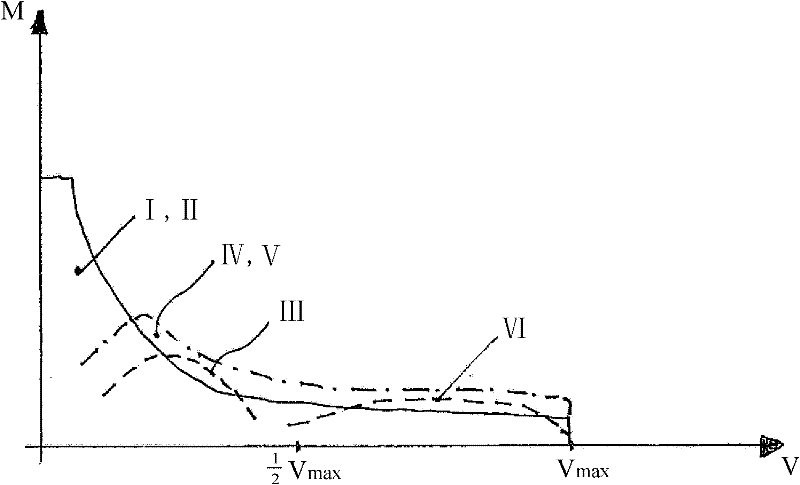

[0027] exist figure 1 An exemplary construction of the drive device 1 according to the invention can be seen in the description of . The drive device 1 can be used for various drive purposes. For example, the drive device can be used to drive a vehicle (not shown in detail), in particular a commercial vehicle or a passenger car. The drive device 1 comprises an internal combustion engine 2 , which is typically designed as a diesel engine in the above-mentioned example of a commercial vehicle, as well as a first electric machine 3 and a second electric machine 4 . Furthermore, in the exemplary embodiment shown here, the drive device 1 also has a transmission 5 . The internal combustion engine 2 is connected to the rotor 7 of the first electric machine 3 via a per se known and usual torsional vibration damper 6 , which can be designed as a vibration damper and / or damper. The first electric machine 3 is designed as a transverse flux machine, so that a rotor 7 which moves, for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com