Hollow building block manufactured from electrolytic manganese residues and manufacture method thereof

A technology of electrolytic manganese slag and hollow blocks, which is applied in the field of hollow blocks, can solve the problems of consuming land resources, affecting groundwater resources, increasing the cost of land requisition and site disposal of waste residues piled up by enterprises, and achieving the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

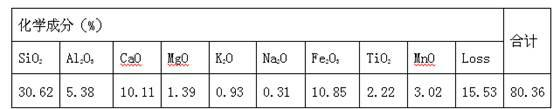

Image

Examples

Embodiment 1

[0022] Embodiment 1: Take by weighing electrolytic manganese slag 50kg, fine aggregate (sand) 32kg, cement 15kg, quicklime 2.5kg, gypsum 0.5kg and water 7.1kg, wherein quicklime and gypsum are the product after grinding through 80 mesh sieve respectively, Add water into the forced mixer, and add the rest of the raw materials while stirring according to the order of electrolytic manganese slag, sand, quicklime, gypsum, and cement. The formed electrolytic manganese slag hollow block was cured in a 1 MPa autoclave for 10 hours to obtain the electrolytic manganese slag hollow block.

Embodiment 2

[0023] Embodiment 2: Take by weighing electrolytic manganese slag 45kg, fine aggregate (sand) 35kg, cement 17.5kg, quicklime 2kg, gypsum 0.5kg and water 7.0kg, wherein quicklime and gypsum are the product after grinding through 80 mesh sieve respectively, First mix cement, quicklime and gypsum evenly, add water to the mixer, then add electrolytic manganese slag to the mixer and stir for 2-10 minutes, add sand and stir for 2-5 minutes, add cement mixture and stir for 2-8 minutes, mix well and put it into the hollow In the block mould, pressurization is used to form, and then the formed electrolytic manganese slag hollow block is cured for 28 days under natural conditions above 5°C to obtain the electrolytic manganese slag hollow block.

Embodiment 3

[0024] Example 3: Weigh 55kg of electrolytic manganese slag, 30kg of fine aggregate (sand), 13.5kg of cement, 1.3kg of quicklime, 0.2kg of gypsum and 6.0kg of water, wherein the quicklime and gypsum are respectively ground and passed through an 80-mesh sieve. First, mix cement, quicklime and gypsum evenly, add water to the mixer, then add electrolytic manganese slag to the mixer and stir for 2-10 minutes, add sand and stir for 2-5 minutes, add cement mixture and stir for 2-8 minutes, and put it into the In the hollow block mould, it is formed by pressurization, and then the formed electrolytic manganese slag hollow block is cured in a 0.8MPa autoclave for 12 hours to obtain the electrolytic manganese slag hollow block.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com