Method for extracting lipid from Chlorella sorokiniana CS-01

An extraction method and technology of chlorella, applied in the direction of fat production, fat oil/fat production, etc., can solve the problem of less application of cell crushing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Cultivation, collection and drying of algal species

[0026] Chlorella sorokiniana CS-01 (CCTCC M 209220), culture conditions: BG-11 medium (published formula), light intensity 70μmol photons m -2 the s -1 , photoperiod 10:14 (L / D), temperature 25±1°C, air flow 2.817vvm (use 0.22μm filter head, filter to sterilize). The growth curve (OD) was determined by absorbance photometry. 680 ), cultivated to the middle and late stages of logarithmic growth, collected the algal bodies by centrifugation at 6000rpm for 10 minutes, and washed the algae bodies twice with sterile water. The algae mud was vacuum freeze-dried for 8 hours, and stored in a desiccator for future use.

[0027] 2. Ultrasonic crushing

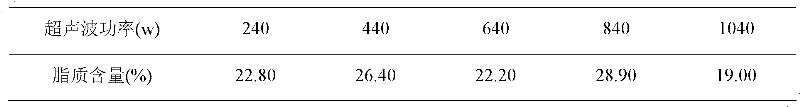

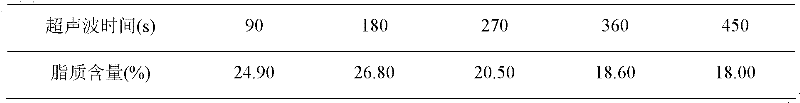

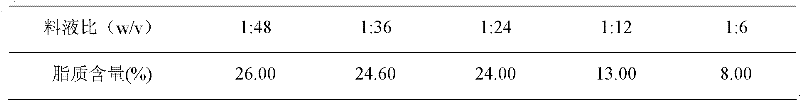

[0028] Chloroform / methanol volume ratio (1:2), solid-liquid ratio (1g:36ml) vibration extraction (15-45s), ultrasonic crushing (440W, 180s), then add 1 / 2 times the volume of water and 1 / 3 Doubling the volume of chloroform solution, ultrasonic crushing (440W, 180s), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com