Ti-Zr composite deoxidized steel used for ultrahigh-strength hull structure, and production process thereof

A technology of structural steel and ultra-high strength, which is applied in the field of low-alloy high-strength steel production, which can solve the problems of reducing the high-temperature strength of steel and achieve good cold-bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

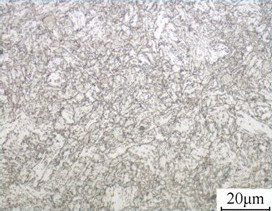

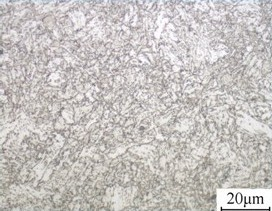

Image

Examples

Embodiment Construction

[0026] A kind of Ti, Zr compound deoxidation of the present invention super-high-strength hull structure steel, design composition by weight percentage is: C: 0.09%, Si: 0.28%, Mn: 1.5%, P: 0.008%, S: 0.001%, Als: 0.006%, Nb: 0.024%, Ti: 0.012%, Zr: 0.008%, Cr+Mo+Ni+Cu=2.0%, the rest is Fe and unavoidable impurities.

[0027] The thickness specification of the finished product produced by the TMCP+RQ+T process adopted in the present invention is: 60mm, including smelting, heating, rough rolling, finish rolling, ACC, quenching, tempering processes, and the specific process steps are:

[0028] Smelt and cast a 220mm thick slab according to the above ingredients; send the slab into the heating furnace, the tapping temperature of the heating furnace is 1180°C, and the heating time is 266min; the rough rolling start temperature is 1100°C, and the rough rolling finish rolling temperature is 1000°C; The thickness of billet to be warmed is 90mm; the starting temperature of finish roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com