Earth pressure balance type annular shield machine

An earth pressure balance and shield machine technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of crowded underground space, abandoned tunnels occupying underground space, and abandoned tunnels are damaged and failed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

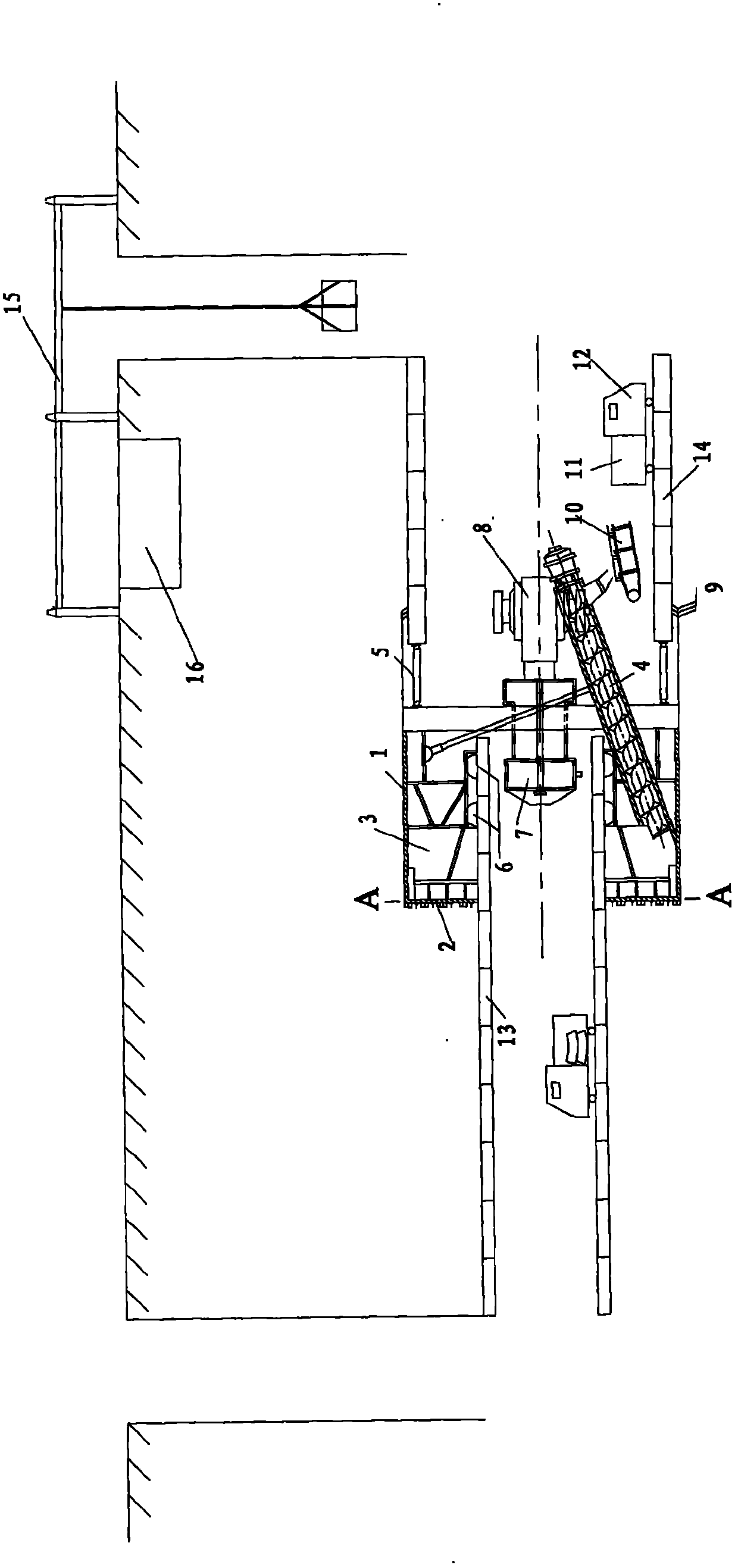

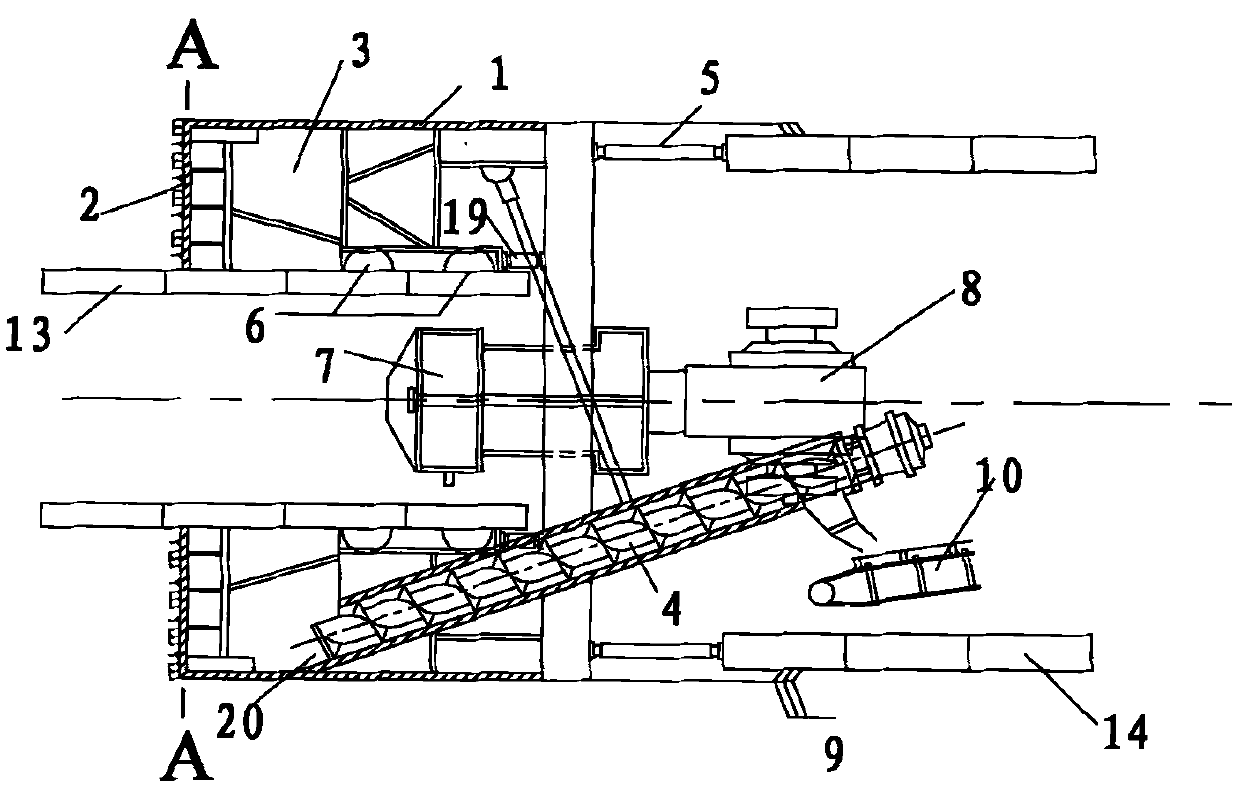

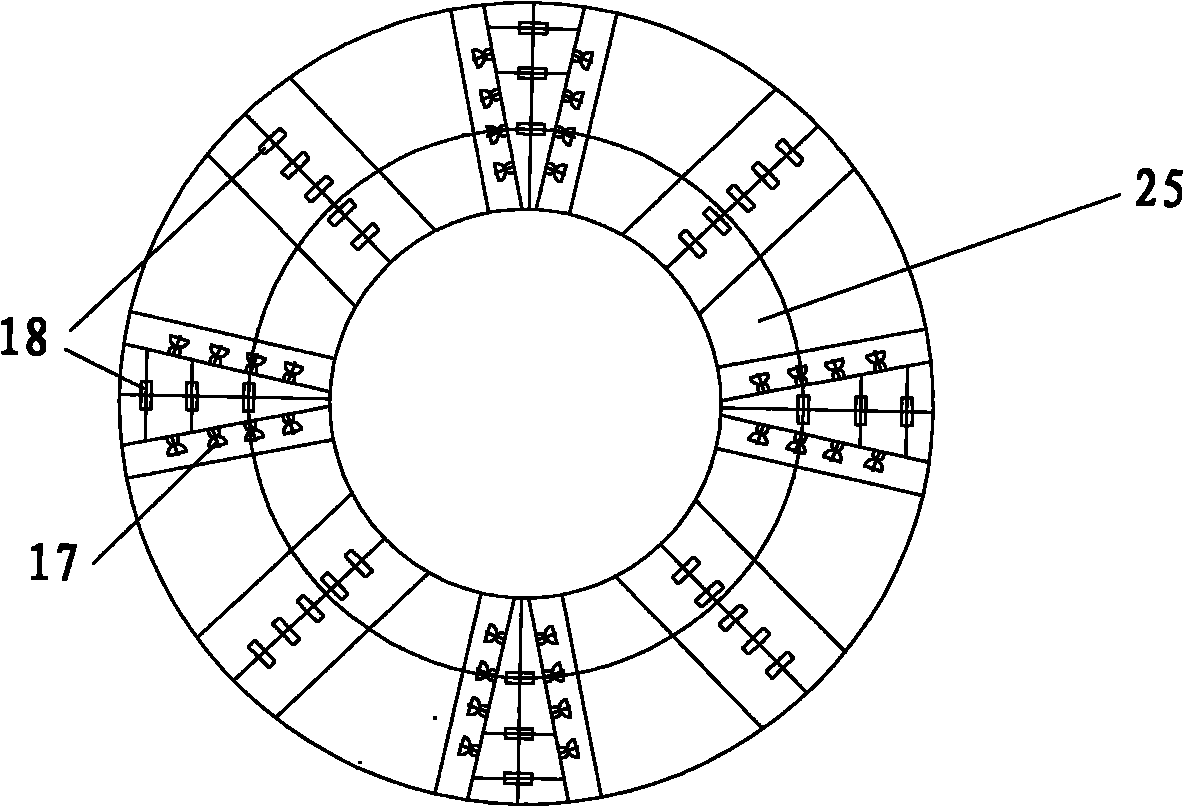

[0022] An earth pressure balance ring shield machine, its structure is as follows Figure 1-Figure 4 As shown, the shield machine includes a shield machine shell 1, an annular cutter head 2, an earth ballast chamber 3, a screw conveyor 4, a propulsion cylinder 5, a gasket 6, a segment removal machine 7, a segment assembly machine 8 and The sealing brush 9 and the annular cutter head 2 are arranged on the front part of the shield machine shell 1, and the tearing knife 17 and the cutting knife 18 are arranged on the annular cutter head 2 at the same time, and the tearing knife 17 is crushed by squeezing and rolling itself hard rock. Run into soft soil layer, tearing knife 17 loses its effect, this moment relies on cutting knife 18, relies on the rotation of cutter head 2 bearings 25, cuts soft soil. The actual shield propulsion is a combination of the two knives.

[0023] The rear part of the cutterhead 2 is an earth ballast chamber 3, and the bottom of the earth ballast chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com