Data collecting method for X-Y galvanometer scanning ultra-spectral image

A technology of galvanometer scanning and acquisition methods, which is applied in spectrometry/spectrophotometry/monochromator, absorption/scintillation/reflection spectroscopy, spectrum investigation, etc., which can solve the problem of large mechanical structure and cost of the push-broom system. High, small scanning field of view and other issues, to achieve the effect of large scanning field of view, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

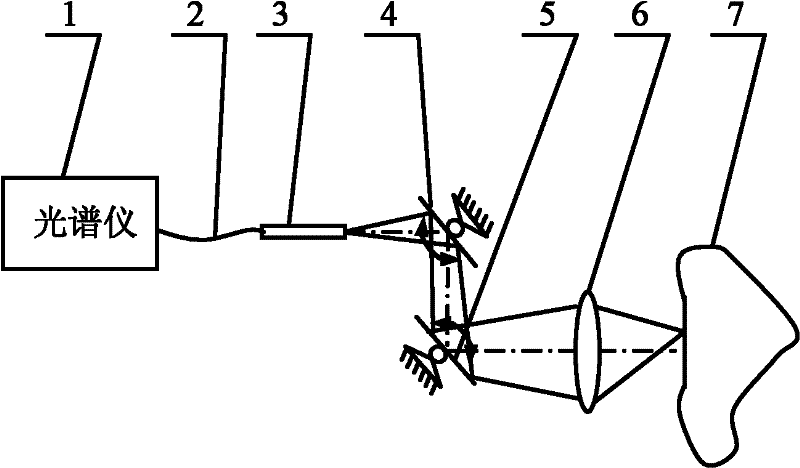

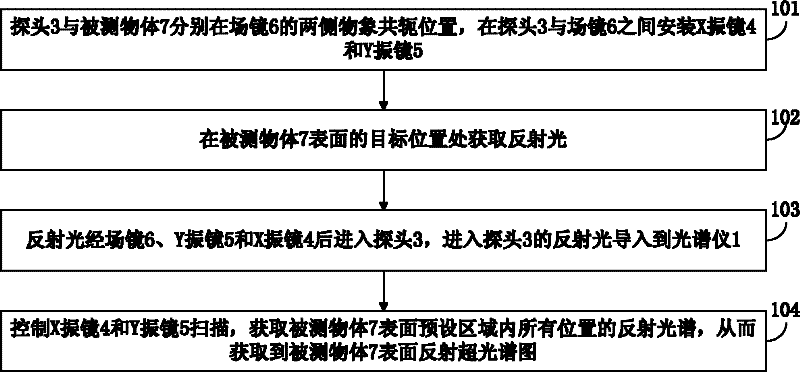

[0045] Embodiment 1: as figure 1 As shown, the probe 3 and the measured object 7 are respectively at the object image conjugate positions on both sides of the field mirror 6, and the X galvanometer 4 and the Y galvanometer 5 are installed between the probe 3 and the field mirror 6; the external illumination light is on the measured object 7 Reflection occurs at the target position on the surface to obtain reflected light; the reflected light enters the probe 3 after passing through the field mirror 6, Y galvanometer 5 and X galvanometer 4, and the reflected light entering the probe 3 is introduced into the spectrometer 1 through the optical fiber 2; the spectrometer 1 pairs The reflected light is sampled to obtain the reflection spectrum; by controlling the X galvanometer 4 and the Y galvanometer 5, the reflection spectrum of all positions in the preset area on the surface of the measured object 7 is obtained, thereby obtaining the surface reflection hyperspectral map of the me...

Embodiment 2

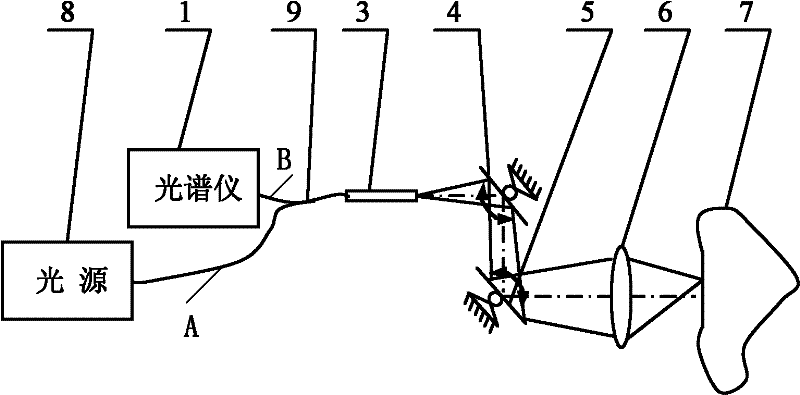

[0046] Embodiment 2: as figure 2 As shown, the probe 3 and the measured object 7 are respectively at the image conjugate positions on both sides of the field mirror 6, and the X vibrating mirror 4 and the Y vibrating mirror 5 are installed between the probe 3 and the field mirror 6; the light source 8 passes through the Y-shaped optical fiber 9 The A end enters the probe 3, the X vibrating mirror 4, the Y vibrating mirror 5 and the field mirror 6 and illuminates the target position on the surface of the measured object 7, and reflection occurs at the target position to obtain reflected light; the reflected light passes through the field mirror 6, Y vibrating The mirror 5 and the X vibrating mirror 4 enter the probe 3, and the reflected light entering the probe 3 is introduced into the spectrometer 1 through the B end of the Y-shaped optical fiber 9; the spectrometer 1 samples the reflected light to obtain the reflection spectrum; by controlling the X vibrating mirror 4 and Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com