Welding belt bonding device of solar module

A solar module and bonding device technology, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve problems such as shortened life, difficult separation, and inability to apply solar cells to solar modules, to prevent position changes, The effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the solar module ribbon bonding apparatus of the present invention configured as above will be described in detail with reference to the drawings.

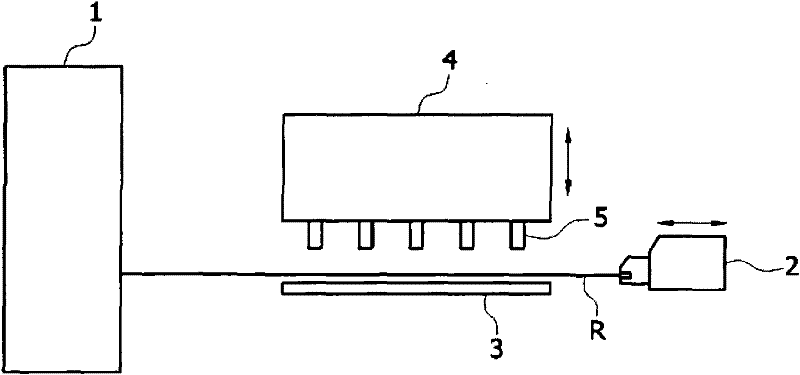

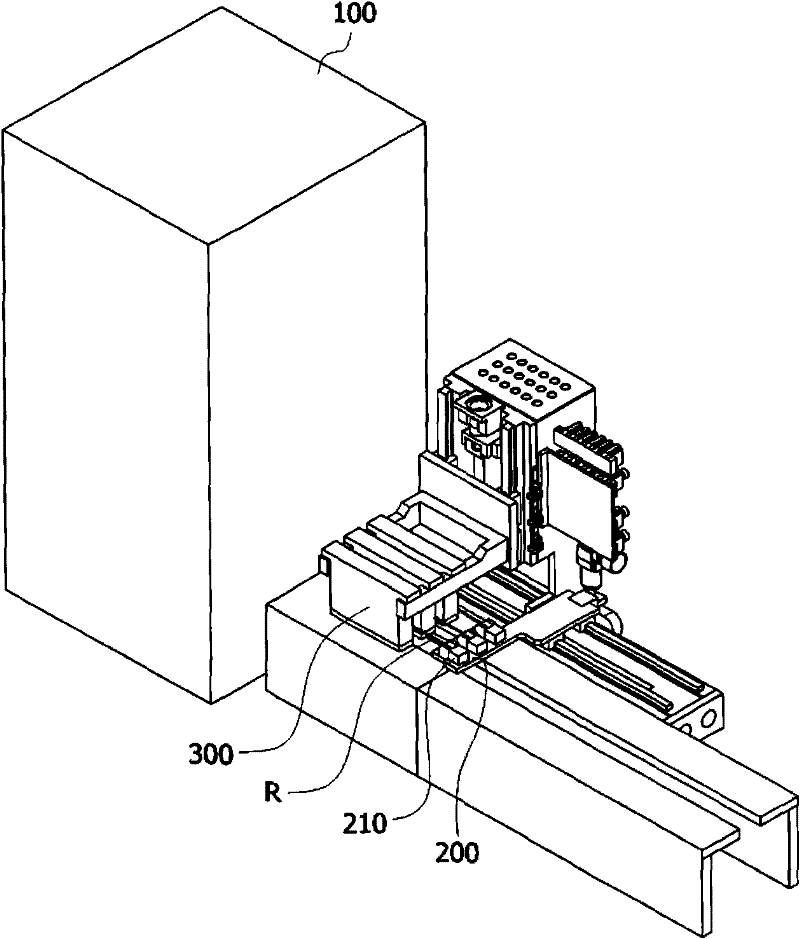

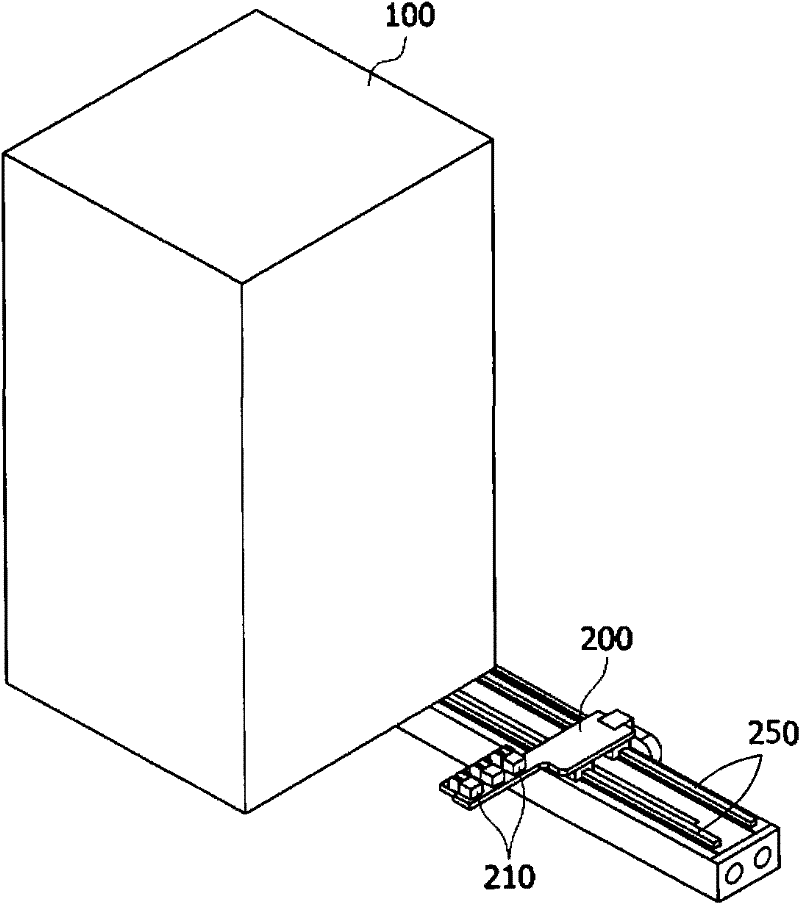

[0037] figure 2 is a configuration diagram of a ribbon bonding device for a solar module according to a preferred embodiment of the present invention.

[0038] refer to figure 2 According to the preferred embodiment of the present invention, the ribbon bonding device for solar modules includes: ribbon supply part 100, used to supply ribbon (ribbon) R; loader 200, clamped by clamp 210 and drawn out The ribbon R supplied by the ribbon supply part 100 is provided with a separation part 220 arranged at the front end of the clamp 210 to separate the ribbon R when the clamp 210 is opened; The welding ribbon R drawn out by the machine 200 is bonded to the solar battery sheet, and according to the separating part 220 , the welding ribbon R is fixed when the welding ribbon R is detached from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com