Process for recycling incineration ash of hazardous wastes

A technology for incineration of ash and hazardous waste, applied in the field of resource treatment, can solve problems such as burning and explosion accidents, difficulty in recovery, human and animal poisoning, etc., and achieve the effects of saving treatment costs, good typicality and demonstration, and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

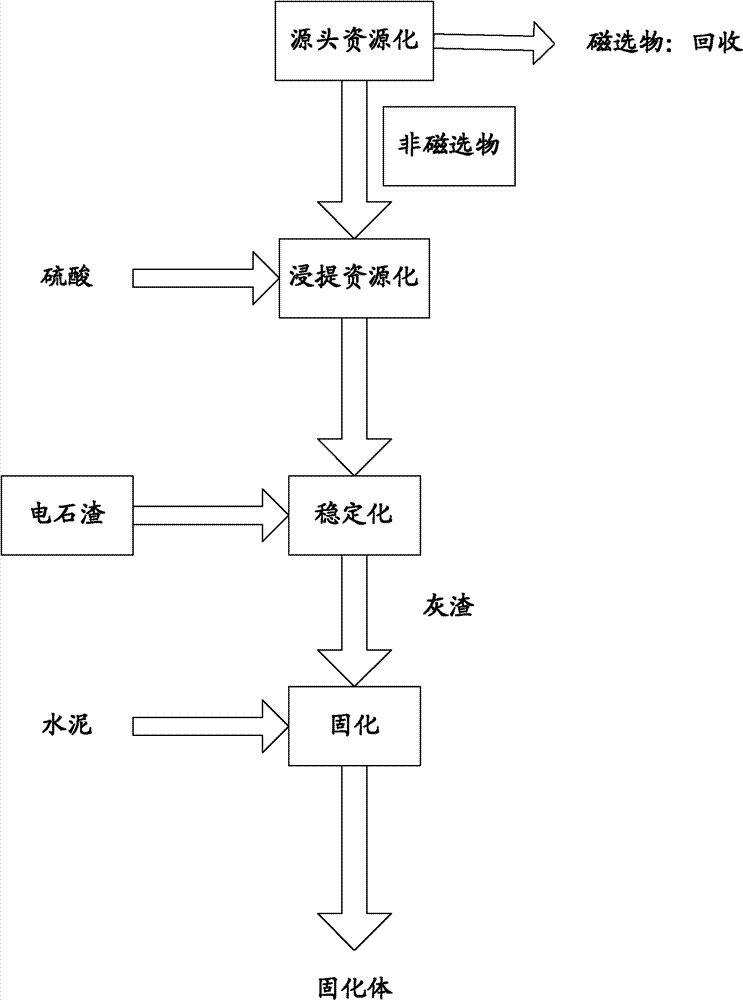

[0028] Adopt resource treatment process of the present invention to process the hazardous waste incineration ash of a certain factory, specifically as follows:

[0029] 1. Source resources:

[0030] The hazardous waste incineration ash that has been air-dried and crushed and passed through a 100-mesh standard sieve is subjected to magnetic separation with magnetic separation equipment. The magnetic separation data and effects are shown in Tables 1-3:

[0031] Table 1 Masses of magnetically separated and non-magnetically separated residue samples after roughing

[0032]

[0033]

[0034] The magnetically separated and non-magnetically separated samples after the above-mentioned magnetic separation are digested respectively, and the digestion method is as follows:

[0035] Accurately weigh 0.5000g sample into a 25ml polytetrafluoroethylene crucible, moisten it with a little water, add 10ml hydrochloric acid, heat (lower temperature) on an electric heating plate in the fum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com