Preparation method of heparin oligosaccharides

A technology of heparin oligosaccharides and heparin, which is applied in the field of preparation of heparin oligosaccharides, can solve the problems of complex process, high yield, and low cost, and achieve the effects of simple process, high yield, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] One embodiment of the present invention, a method for preparing heparin oligosaccharides, comprises the following steps:

[0011] 1) Enzymatic degradation of heparin: Take 20 mg of heparin, dissolve it in 1 ml of reaction solution Digestion Buffer (25 mM ammonium acetate, 25 μM CaCl2, 0.25 μg / ml BSA, pH 7.4), add 500 uL of heparinase I, II, and III each, 37°C constant temperature shaking reaction for 72 hours, in which heparanase was supplemented every 12 hours, after the reaction was completed, heated in a water bath at 100°C for 15 minutes, and centrifuged at 12000 rpm for 10 minutes at high speed, and the supernatant was taken for later use.

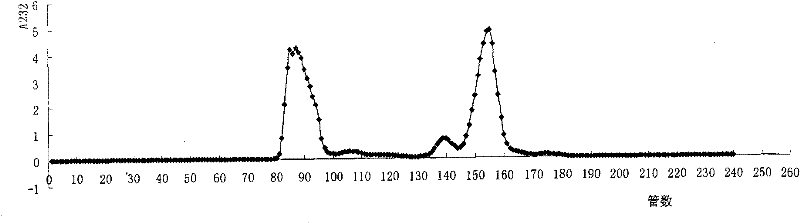

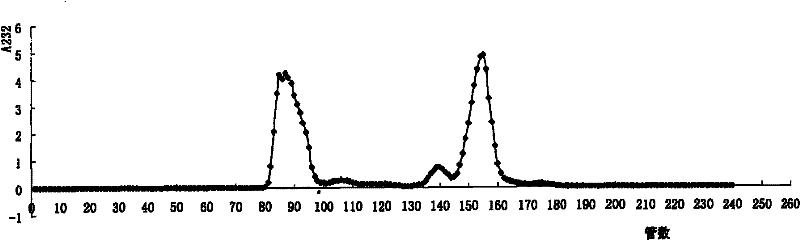

[0012] 2) Fractional purification of heparin oligosaccharides: the oligosaccharide fragments obtained in step 1 are subjected to fractional purification through a Bio-gel P2 column, collected and freeze-dried to obtain a finished product.

[0013] The degraded heparin oligosaccharide fragment has an unsaturated double bond at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com