Manufacturing method of crocodile amour powder

A production method, crocodile technology, applied in the field of calcium powder production, can solve the problems of high power consumption, many impurities in the product, and various processing equipment, etc., and achieve the effect of easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

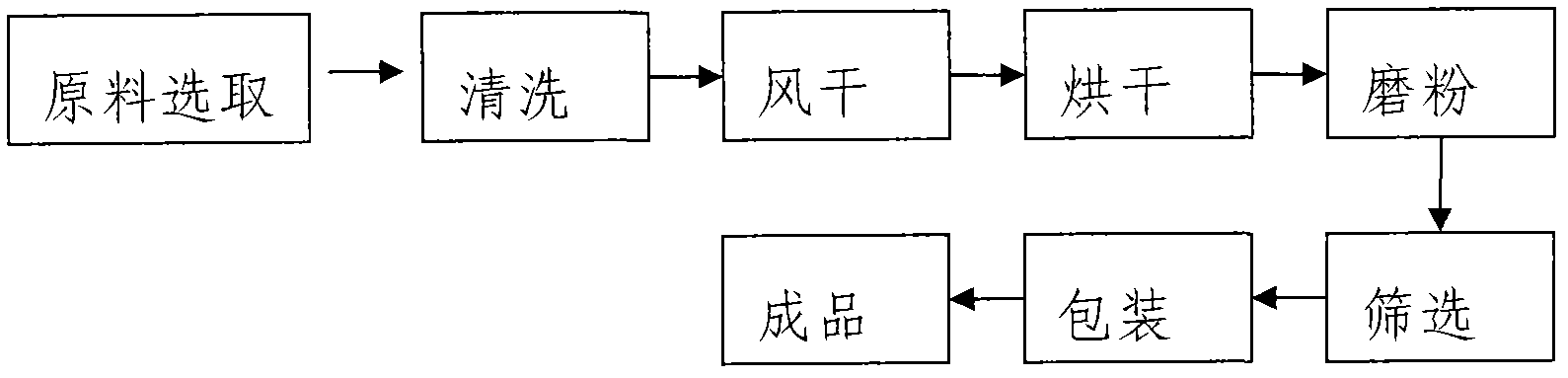

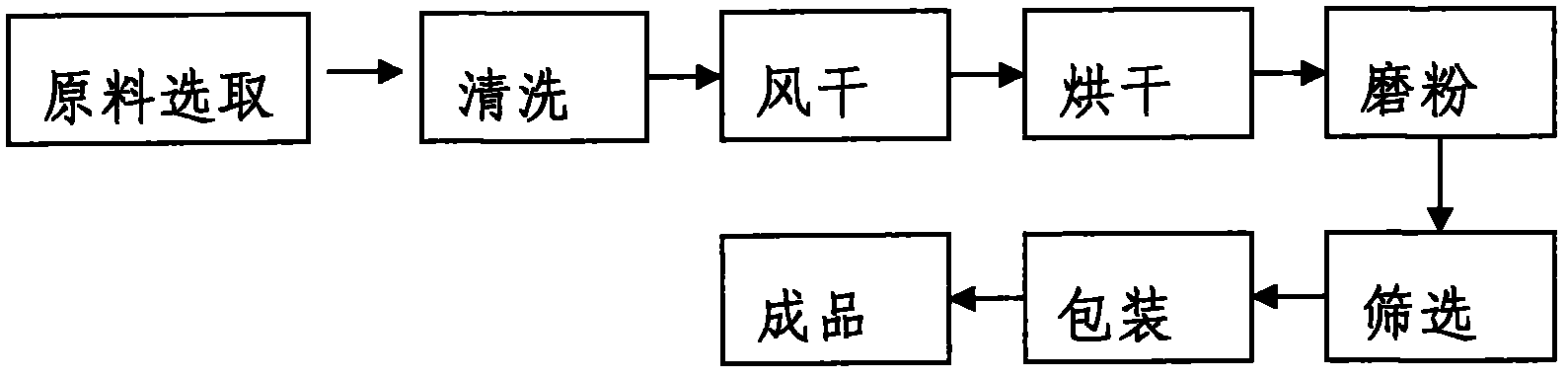

Image

Examples

Embodiment 1

[0009] Embodiment 1: the preparation method of crocodile shell powder

[0010] (1) Selection of raw materials: crocodile armor is obtained from natural or artificially bred crocodiles, which are slaughtered;

[0011] (2) Cleaning: crocodile shells are soaked in clean water, washed repeatedly, and then soaked in salt water with a concentration of 2 to 4% for disinfection. Disinfection with salt water has the advantages of no pollution, good effect, low cost, deodorization, easy purchase and operation Convenience and many other benefits, and finally washed repeatedly with water;

[0012] (3) air-drying: carry out natural air-drying or sun-dried to the cleaned crocodile shell;

[0013] (4) Drying: Utilize the dryer to evaporate and take away the moisture in the crocodile shell to form dry crocodile shell;

[0014] (5) pulverization: pulverize the dried crocodile shells with a pulverizer to form coarse crocodile shell powder;

[0015] (6) Grinding: the coarse crocodile shell po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com