Device and method for preparing egg-type alloy welded ball

A technology for preparing devices and alloys, used in welding equipment, metal processing equipment, welding media, etc., can solve the problems of lack of cooling environment and affecting egg structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

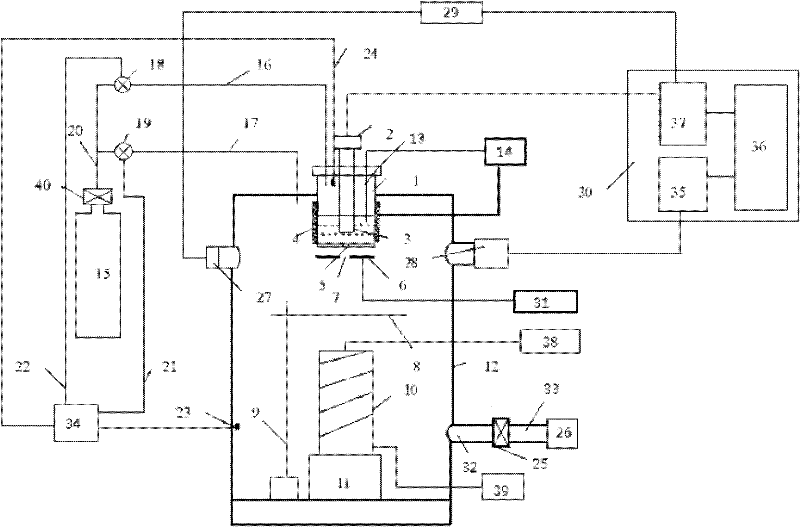

[0036] to attach image 3 As shown, the preparation device of the present invention includes a melting vessel (such as a crucible 1), a piezoelectric oscillator 2, an electrode plate 6, a spiral cooling device 10, a liquid nitrogen storage device 38, a liquid nitrogen recovery device 39, a collector 11, The vacuum chamber 12 is provided with a piezoelectric oscillator 2 on the crucible 1. The piezoelectric oscillator 2 is connected to the signal generator 36 through a control line. The bottom of the crucible 1 is inlaid with a micro nozzle 5. The vibration of the piezoelectric oscillator 2 The head 3 is arranged on the upper part of the microhole 5, the outer wall of the crucible 1 has a heater 4, and the bottom of the crucible 1 has an electrode plate 6, and an opening 7 is arranged in the middle of the electrode plate 6 opposite to the nozzle. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com