Full-automatic and unpowered sealed type oil-water separator

An oil-water separator and oil-water separation tank technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of increased treatment costs, high power consumption, secondary pollution, etc. problems, to achieve the effect of reducing equipment footprint, reducing equipment investment, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

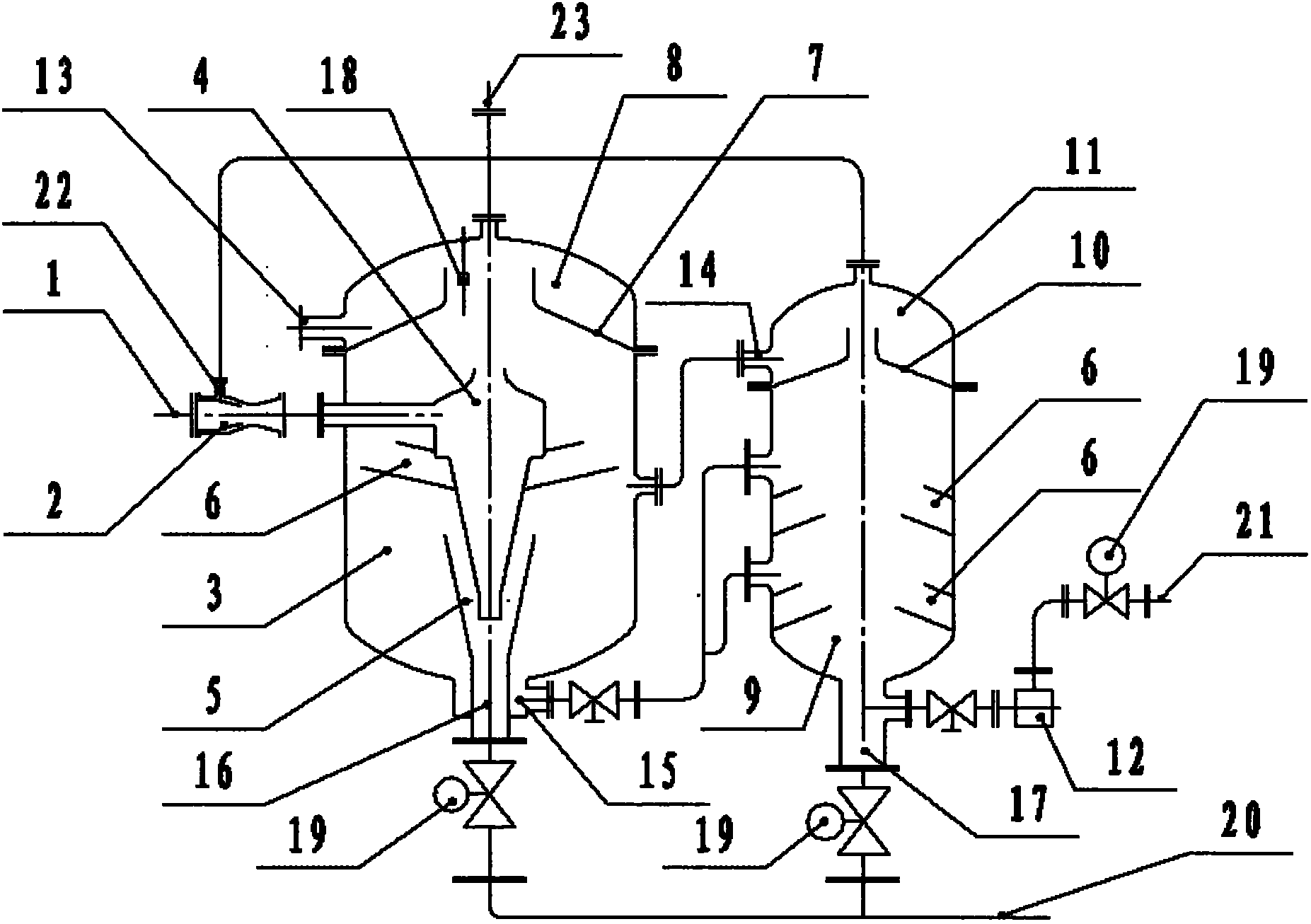

[0031] A fully automatic non-powered sealed oil-water separator of the present invention consists of an oil-water inlet pipe 1, a jet device 2, a first-stage oil-water separation tank 3, a cyclone 4, a mud-sand separation cover 5, an oil-separating cover 6, an oil-collecting Cover (1) 7, oil gathering chamber (1) 8, second stage oil-water separation tank 9, oil gathering cover (2) 10, oil gathering chamber (2) 11, oil filter 12, oil discharge outlet (1) 13 , oil discharge outlet (2) 14, drain outlet (1) 15, mud and sand outlet (1) 16, mud and sand outlet (2) 17, liquid level controller 18, electric ball valve 19, sewage outlet 20, drain (2 ) 21, ejector air inlet 22, external air inlet and outlet 23 and related pipelines and control system, characterized in that: the oily water inlet pipe 1 passes through the ejector 2 and related pipelines and the first stage oil-water separation tank The cyclone 4 in 3 is connected; the upper part of the cyclone is provided with an oil colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com