Catalyst solid component for olefin polymerization and preparation method thereof

A technology for polymerizing solid components and olefins, which is applied in the field of preparation of solid components of olefin polymerization catalysts, and can solve the problems of environmental hazards, complex preparation processes, and low sensitivity to hydrogen adjustment of catalysts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

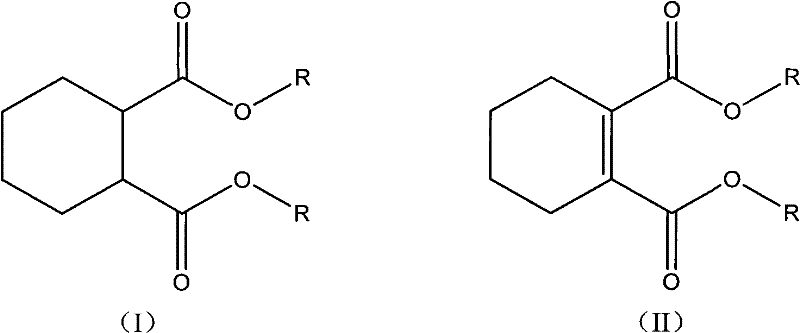

[0044] (1) Add 5g of anhydrous magnesium chloride, 23mL of isooctyl alcohol, 1mL of dimethyl 1-cyclohexene-1,2-dicarboxylate, tetrabutyl titanate and 30mL of dry decane compound into the reaction flask, titanium The molar weights of tetrabutyl ester and di-n-butyl 1-cyclohexene-1,2-dicarboxylate are equal, and they are reacted at 130°C for 4 hours under the protection of nitrogen to fully dissolve anhydrous magnesium chloride and obtain a stable and uniform alcohol compound. solution, and the reaction system was slowly lowered to room temperature.

[0045] (2) Add the homogeneous solution prepared above dropwise to a reactor fully replaced by nitrogen and equipped with 200ml titanium tetrachloride at -20°C within 1 hour. 1ml of di-n-butyl 1-cyclohexene-1,2-dicarboxylate, continue to heat up for 30min until the temperature reaches 110°C, add 1.5ml of di-n-butyl 1-cyclohexene-1,2-dicarboxylate, at this temperature The reaction was carried out for 2 hours. After the reaction wa...

Embodiment 2

[0052] 1-cyclohexene-1,2-dicarboxylic acid di-n-butyl is replaced by 1-cyclohexene-1,2-dicarboxylic acid diisobutyl ester, and others are the same as in Example 1. Catalyst composition analysis results:

[0053] Titanium content: 2.15% (wt)

[0054] Magnesium content: 16.4% (wt)

[0055] Ester content: 8.2% (wt)

[0056] Polymerization result: catalytic activity 47,600gPP / gCat, polymer apparent density 0.46g / cm 3 , The isotacticity is 97.3%.

Embodiment 3

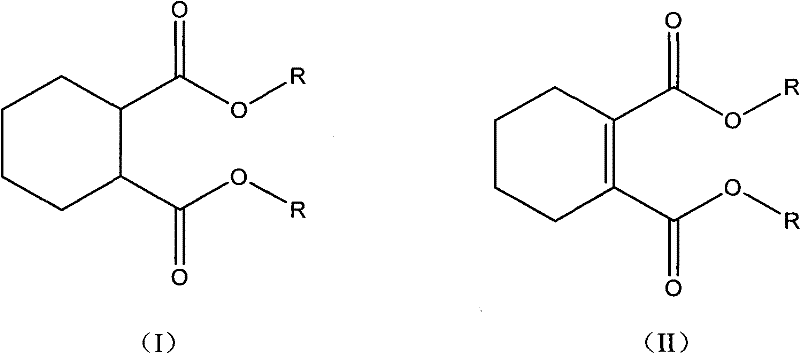

[0058] 1-cyclohexene-1,2-dicarboxylic acid di-n-butyl ester was replaced by cyclohexane-1,2-dicarboxylic acid di-n-butyl ester (equal ratio mixture of cis and trans isomers), and the others were the same as in Example 1. Catalyst composition analysis results:

[0059] Titanium content: 2.25% (wt)

[0060] Magnesium content: 16.6% (wt)

[0061] Ester content: 8.1% (wt)

[0062] Polymerization result: catalytic activity 45,400gPP / gCat, polymer apparent density 0.46g / cm 3 , The isotacticity is 97.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Catalytic activity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Catalytic activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com