Mobile self-cleaning dry dust-collecting and ventilating equipment used in tunnel construction

A technology for tunnel construction and ventilation equipment, which is applied in mine/tunnel ventilation, mining equipment, dust prevention, etc. It can solve problems such as secondary pollution, and achieve the effects of saving operating costs, saving equipment investment, and optimizing ventilation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

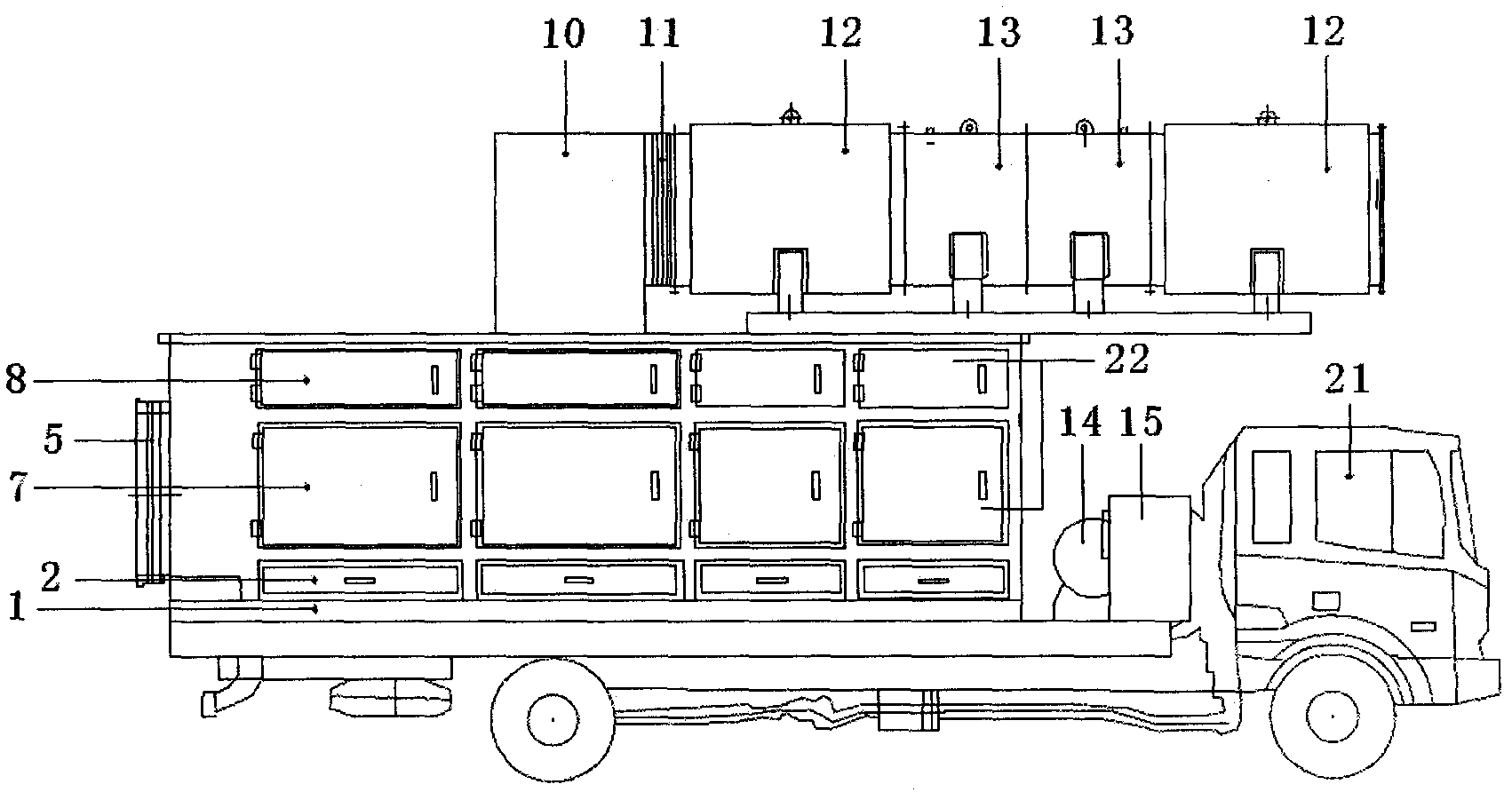

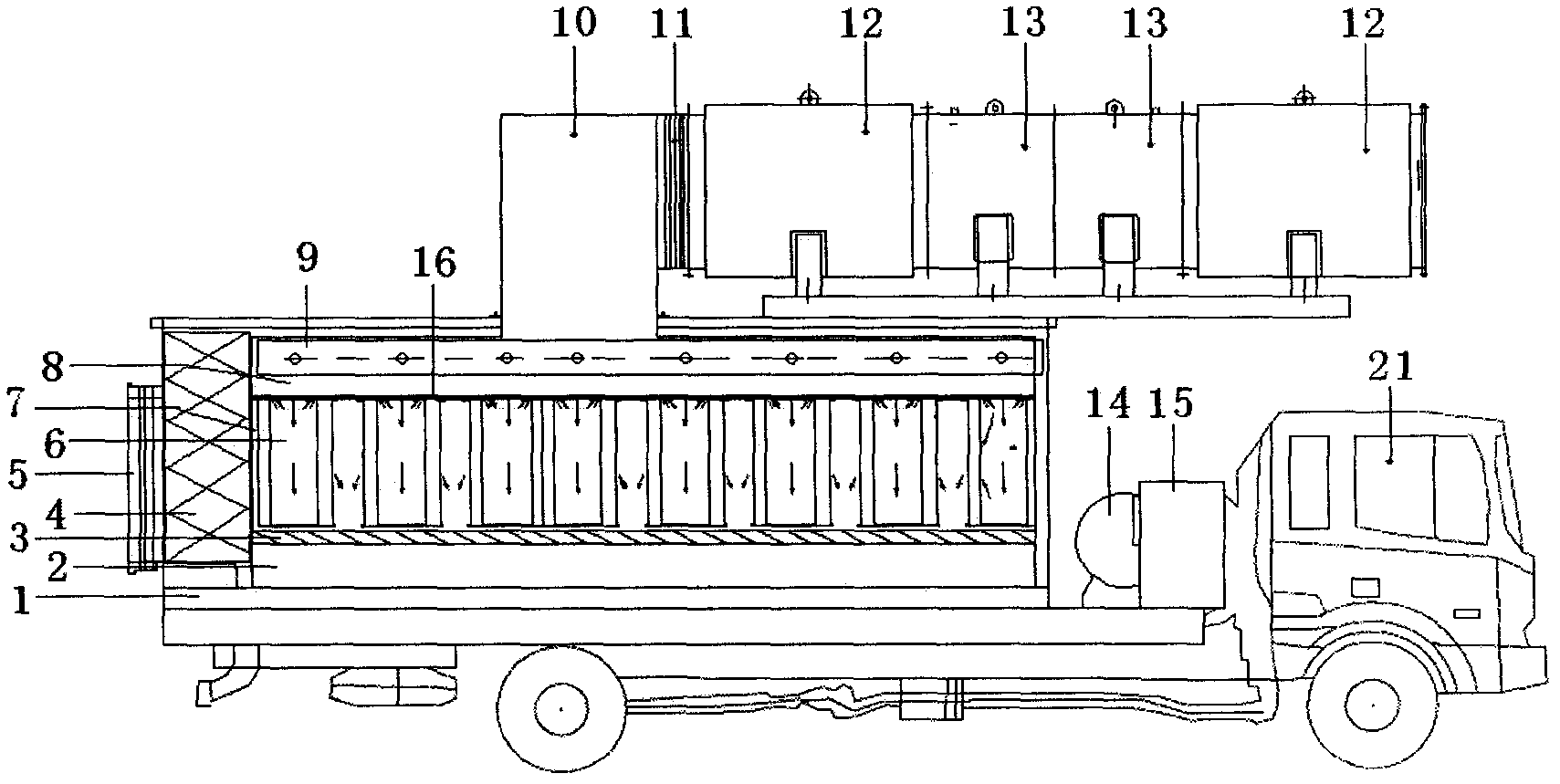

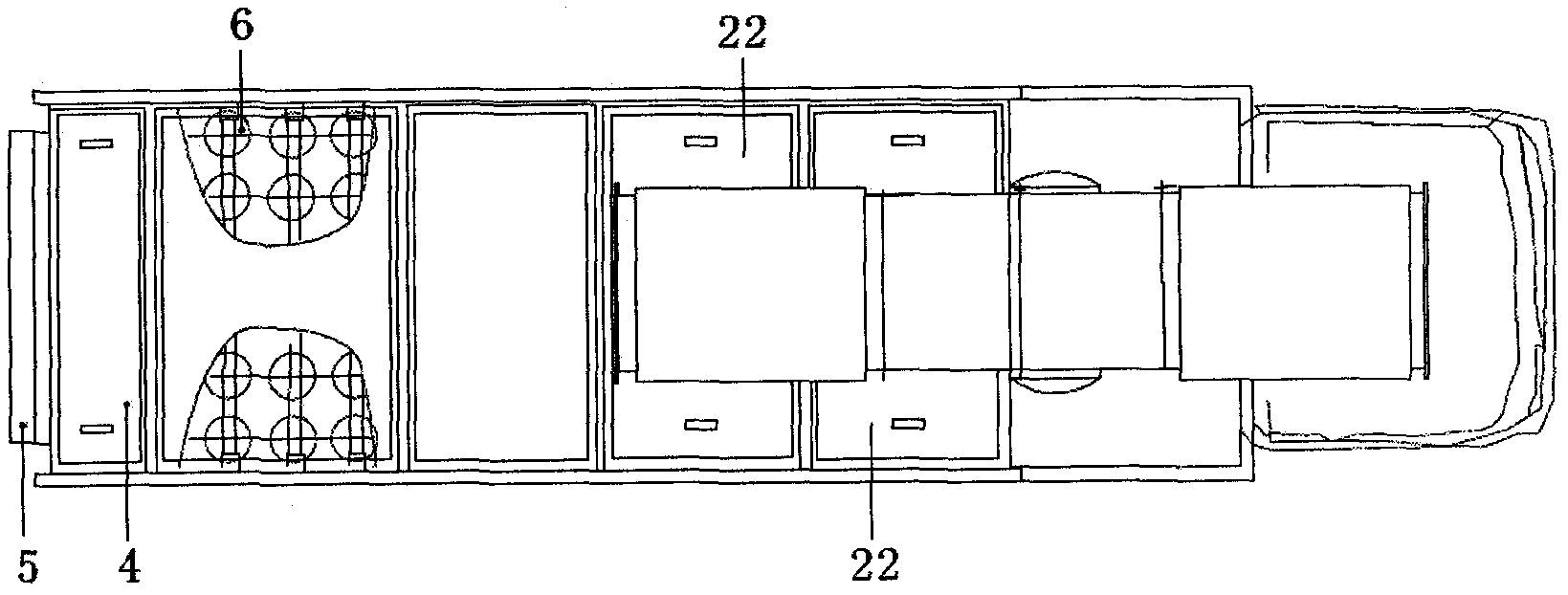

[0019] The equipment of the present invention usually takes a truck as a carrier, and is arranged at the excavation surface. When the dust generated by the tunnel construction and the flue gas produced by the internal combustion engine are sucked into the dust removal box 1 through the dust suction port 5 under the negative pressure generated by the counter-rotating jet fan 13, the large particle dust and The water vapor contained in the dust is separated. The small particle fiber dust (below 5 μm) filtered by the defoaming / demisting device enters the antistatic filter cartridge 6 filter system in the filter box 7 . At this time, negative pressure is also generated in the antistatic filter cartridge 6, and the smoke and dust air outside the filter cartridge enters the antistatic filter cartridge 6 under the action of pressure difference, and the dust is blocked on the outer surface of the filter cartridge, and the blocked dust falls into the collector under the action of gravi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com