Jet-flow air pre-heater with heat exchange tubes having same inlet and outlet temperature difference

An air preheater and heat exchange tube technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc. The problems of high cost and uneven thermal expansion of heat exchange tubes can achieve the effect of reducing temperature, reducing material cost and improving total heat transfer coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

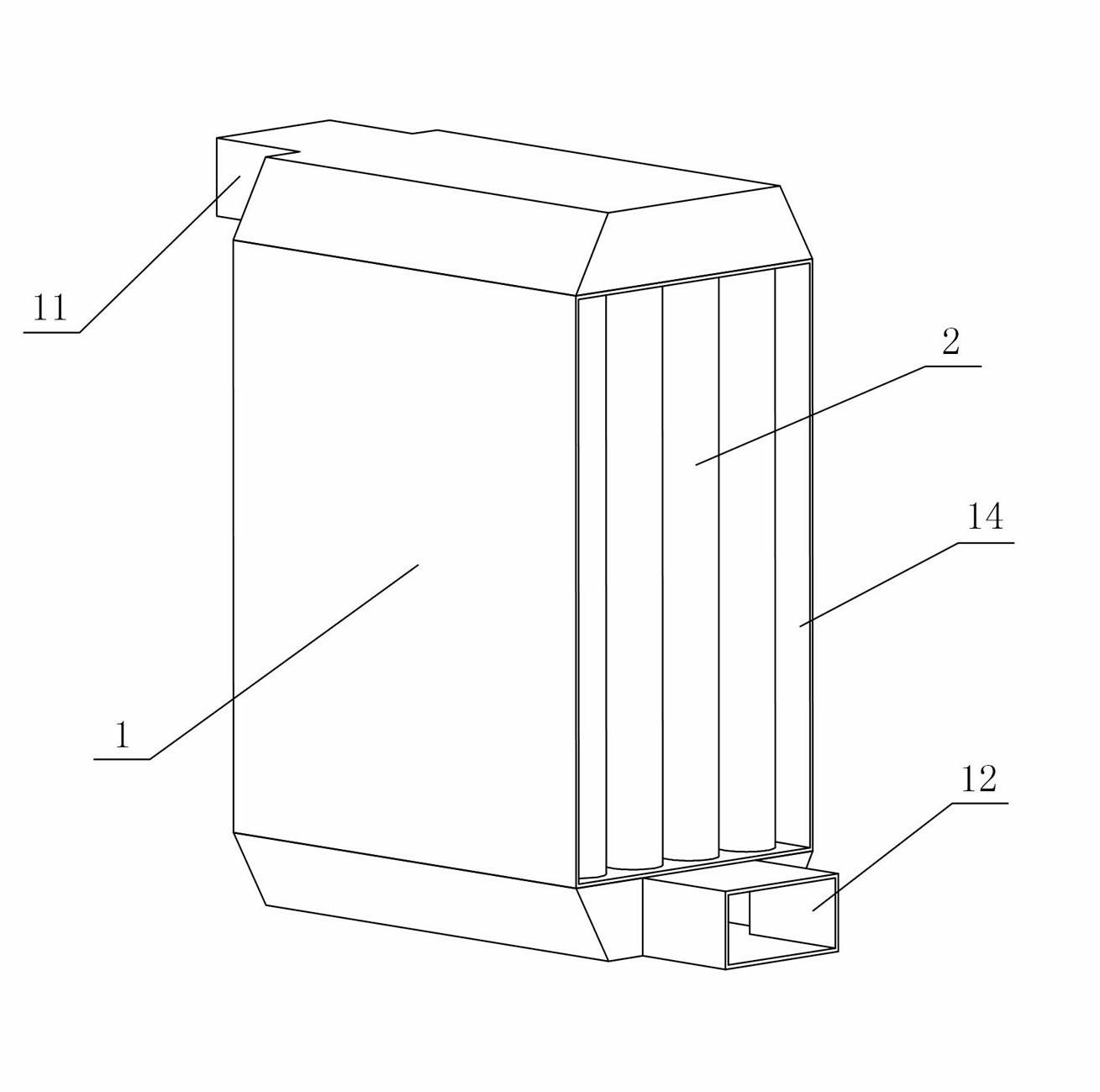

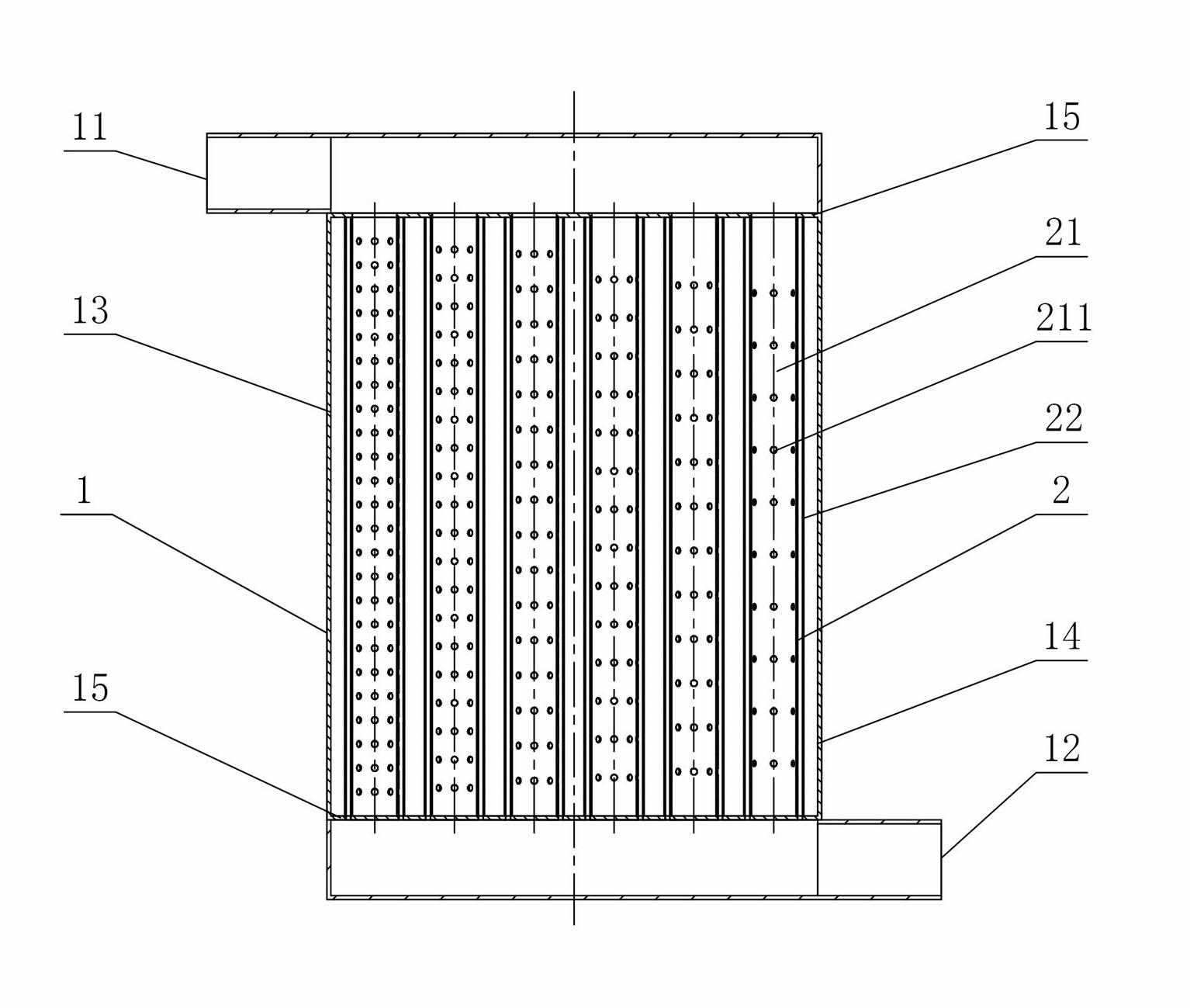

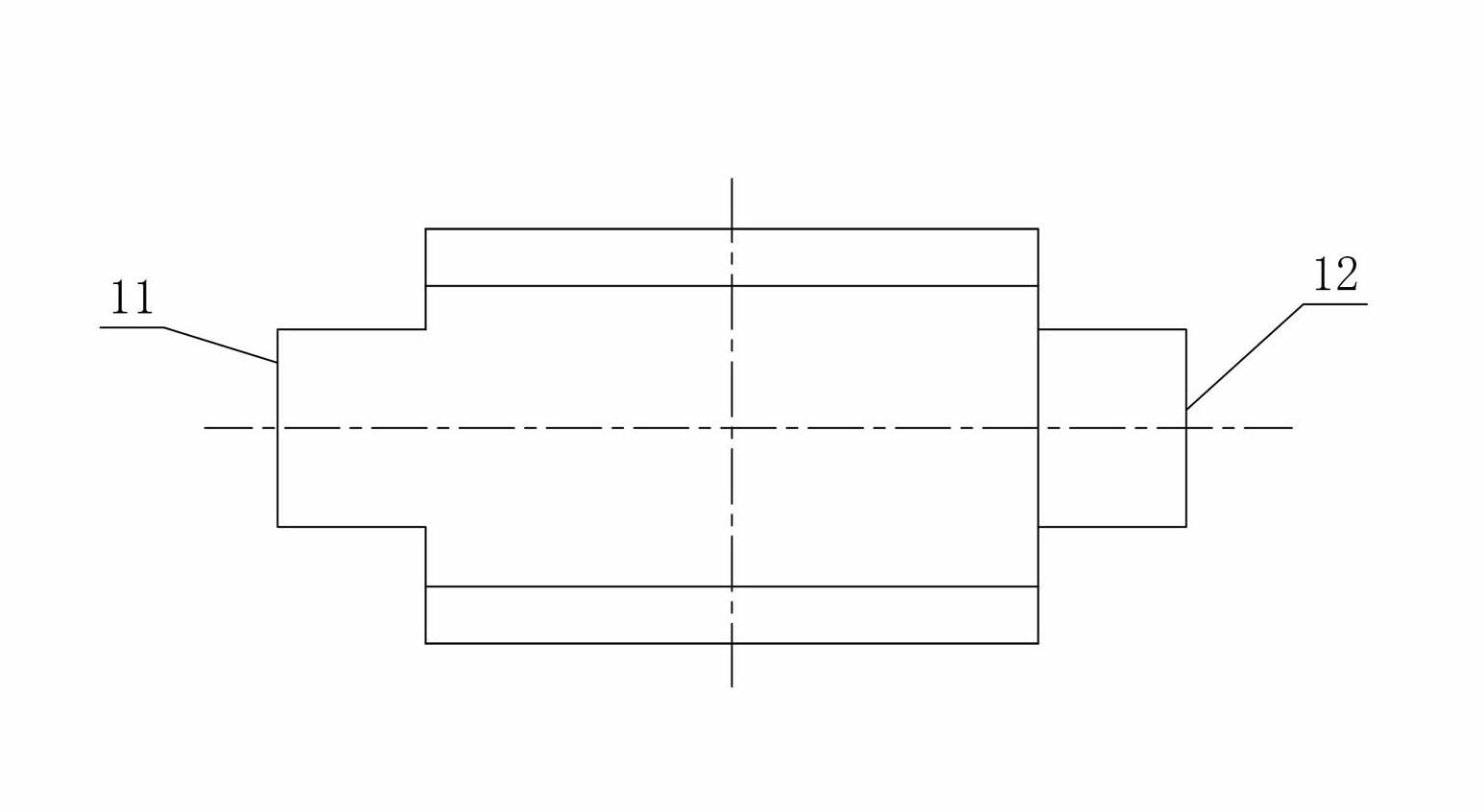

[0019] Figure 1 to Figure 4 It shows an embodiment of a jet-flow air preheater with the same temperature difference between the inlet and outlet of the heat exchange tubes of the present invention. The preheater includes an air box 1 and multiple rows of heat exchange tubes 2. The upper end of the air box 1 is provided with a cold air inlet 11. The lower end of the bellows 1 is provided with a hot air outlet 12, one side of the bellows 1 is provided with a flue gas inlet 13, the other side of the bellows 1 is provided with a flue gas outlet 14, the cold air inlet 11 is located near the side of the flue gas inlet 13, and the hot air outlet 12 is located on the side close to the flue gas outlet 14. There are two upper and lower connecting plates 15 inside the bellows 1, and the flue gas inlet and outlet are separated from the air inlet and outlet by the two connecting plates 15. Multiple rows of heat exchange tubes 2 are evenly arranged In the bellows 1 and connected to the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com