Temperature control type 10G 80km SFP+ (enhanced 8.5 and 10 gigabit small form factor pluggable module) optical module with low power consumption

A technology of temperature control and low power consumption, which is applied in the coupling of optical waveguides, electromagnetic wave transmission systems, electromagnetic transceivers, etc., can solve problems such as difficulty in adapting to requirements, and achieve good high-frequency debounce characteristics, overall performance optimization, and performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Design a temperature-controlled, long-distance, low-power 10G 80km SFP+ optical module that meets the SFP+ protocol standard, high integration, simple circuit, low power consumption, small size, and high cost performance.

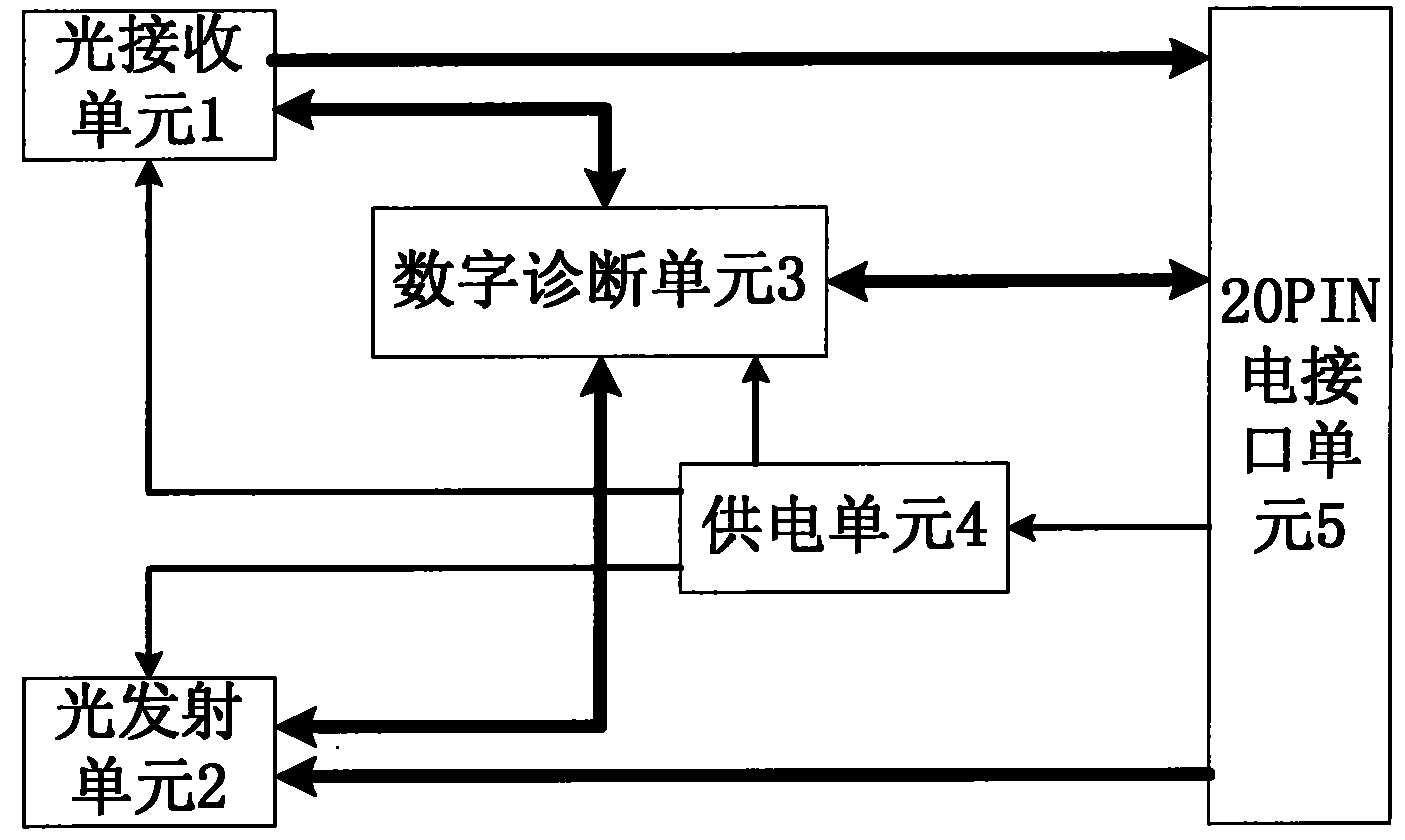

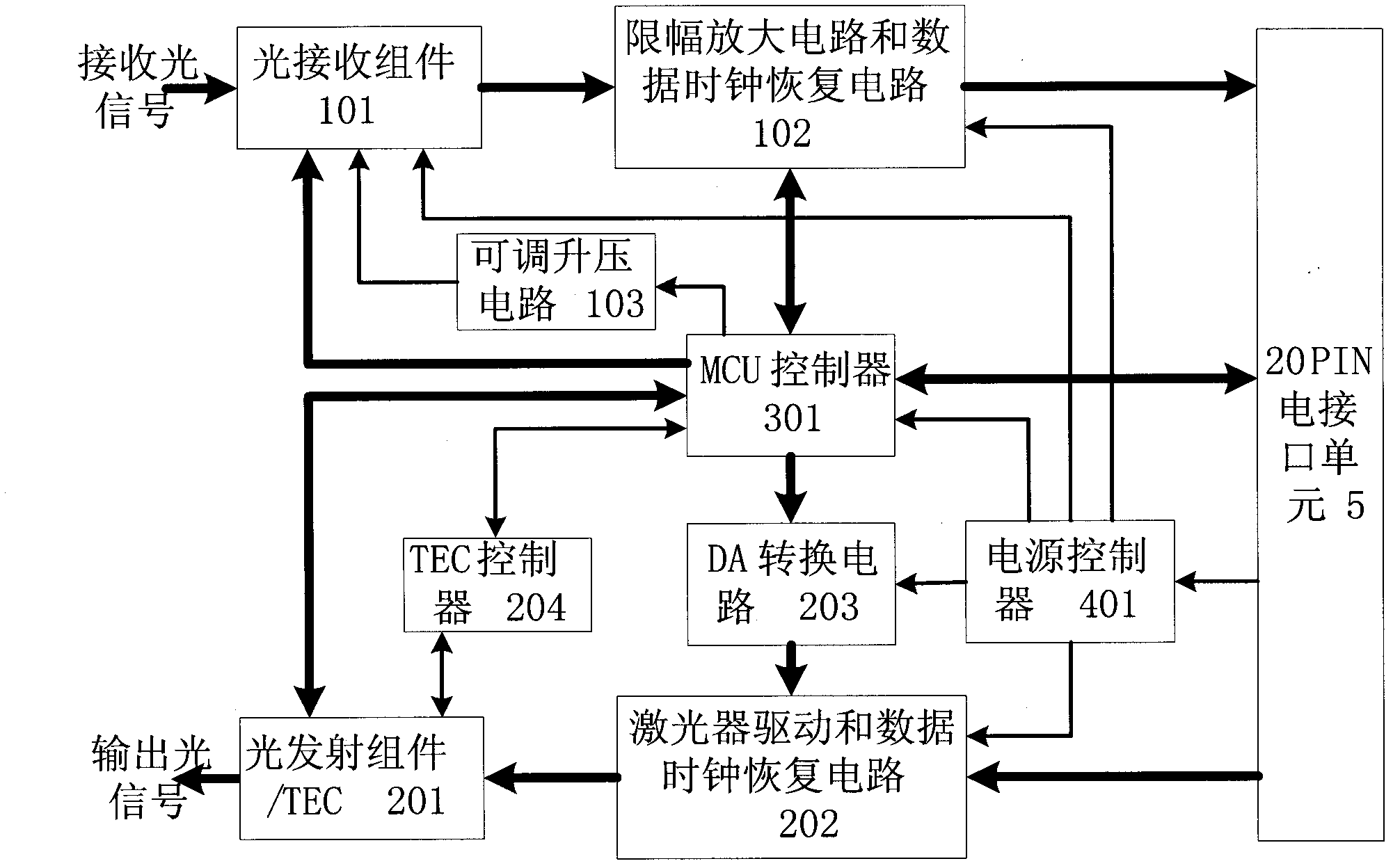

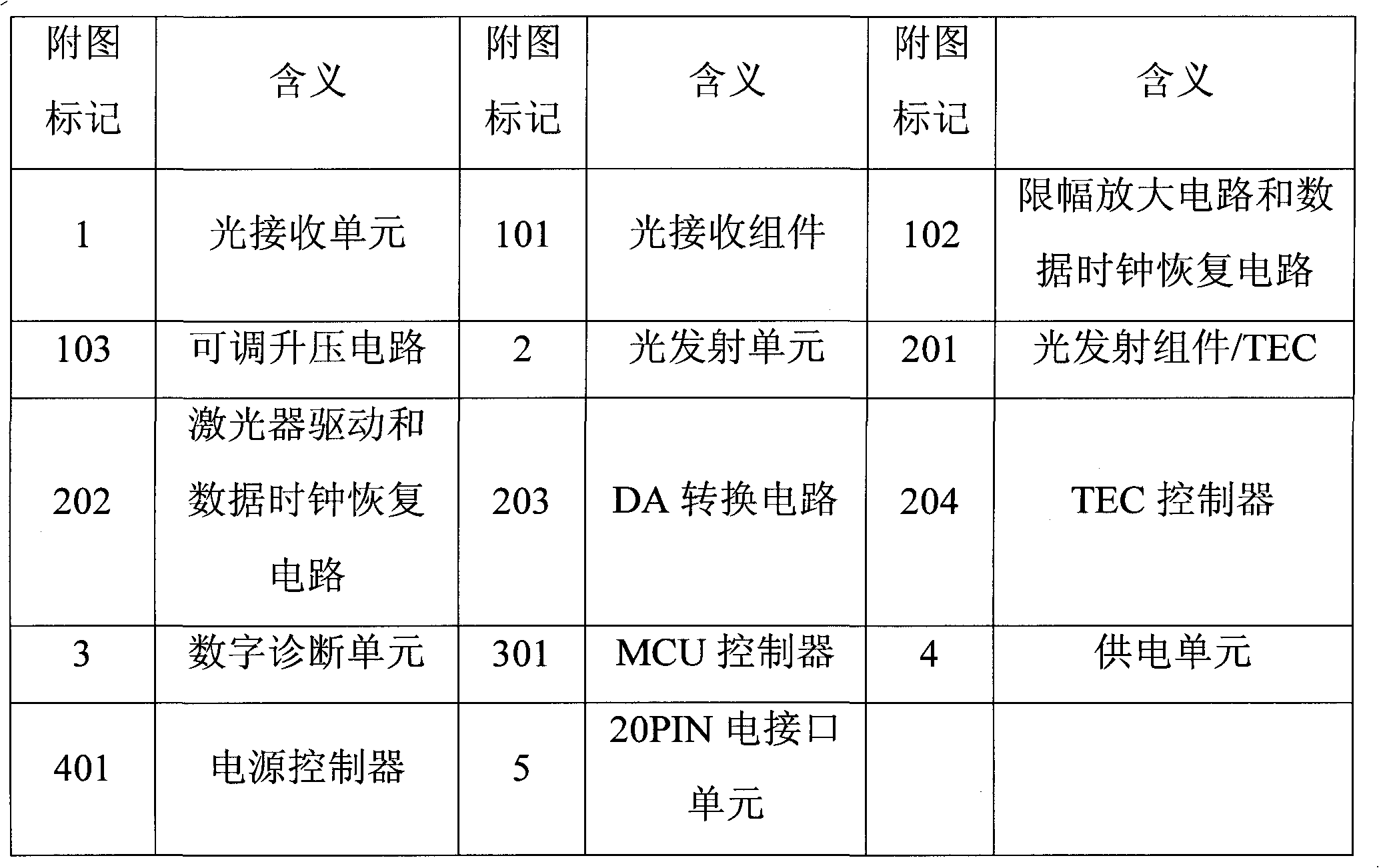

[0026] Such as figure 1 As shown, the temperature-controlled low-power consumption 10G 80km SFP+ optical module includes an optical receiving unit 1, an optical transmitting unit 2, a digital diagnostic unit 3, a power supply unit 4, and a 20PIN electrical interface unit 5. The power supply unit 4 is connected to the optical receiving unit 1 respectively. , light emitting unit 2, digital diagnostic unit 3 and 20PIN electrical interface unit 5 are connected to provide power input; light receiving unit 1 is connected to digital diagnostic unit 3 to provide light detection signal; light emitting unit 2 is connected to digital diagnostic unit 3 to provide Light detection signal; The light receiving unit 1 is connected with the 20PIN electrical interface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com