Wafer lens array forming method, forming die, and wafer lens array

A lens array, wafer-level technology, applied in the direction of lens, color TV parts, TV system parts, etc., to achieve the effect of suppressing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

[0053] First, the structure of the wafer-level lens array, lens module, and camera module will be described.

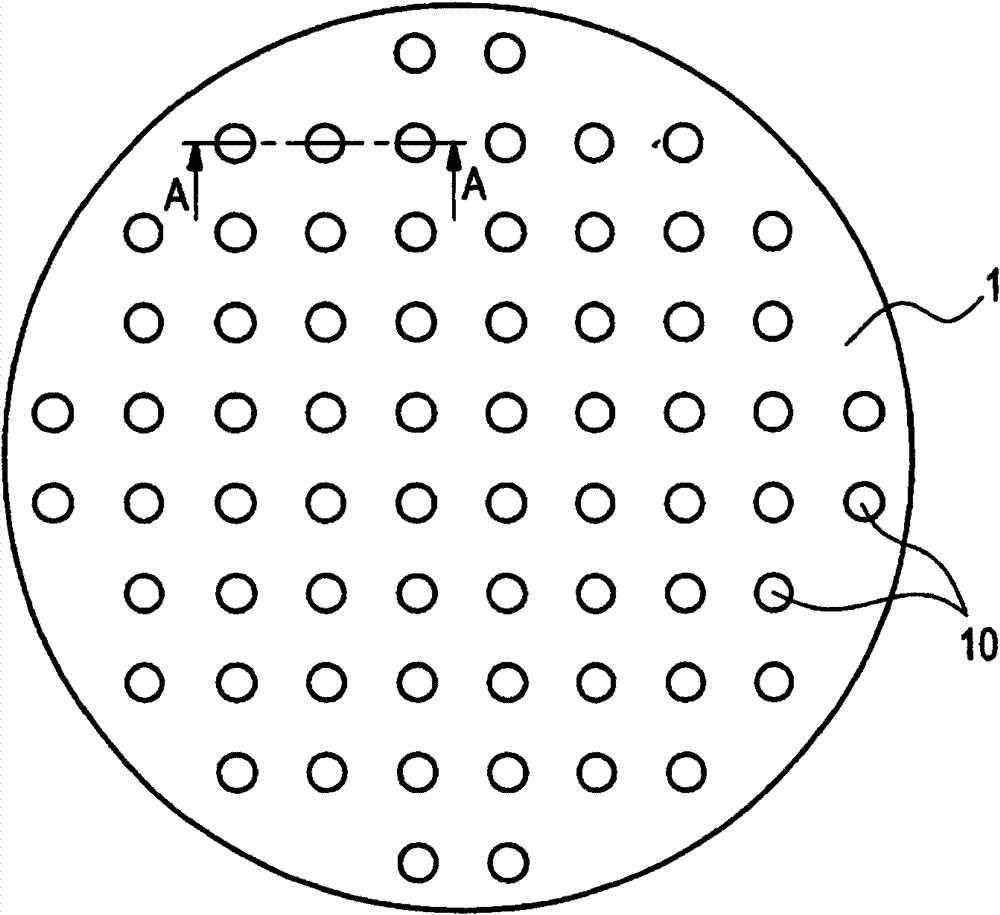

[0054] figure 1 is a top view of the wafer-level lens array. The wafer-level lens array has a substrate unit 1 and a plurality of lens units 10 arranged on the substrate unit 1 .

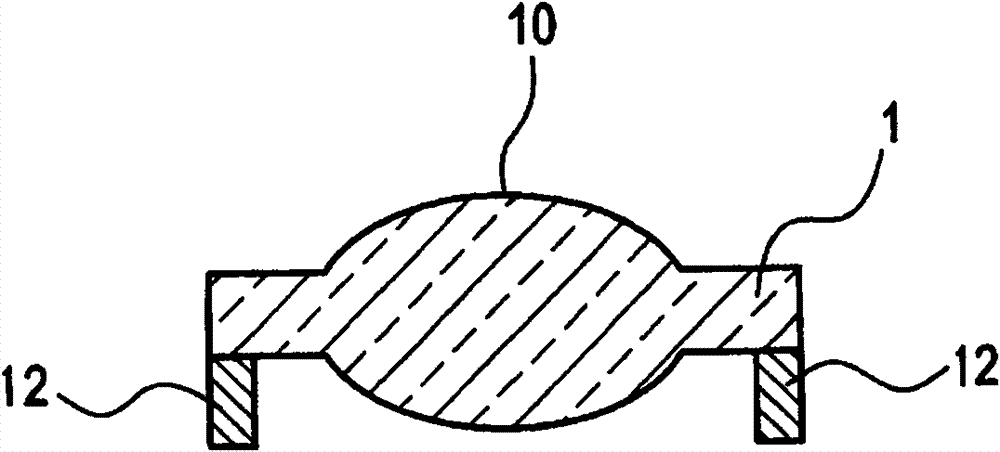

[0055] The lens unit 10 is made of the same material as the substrate unit 1 and is integrally formed on the substrate unit 1 .

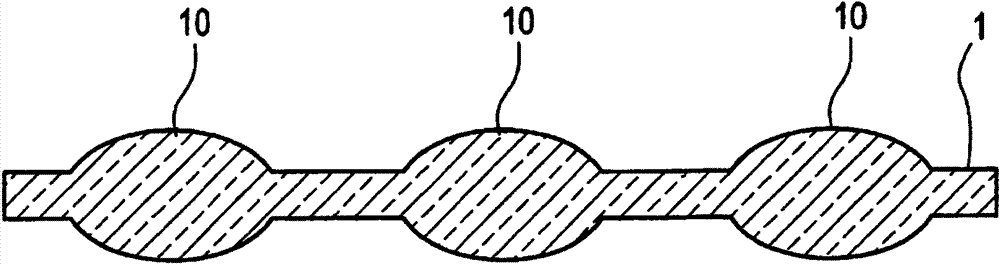

[0056] figure 2 yes figure 1 A-A cross-sectional view of the wafer-level lens array shown. The lens portion 10 formed on the substrate portion 1 has a convex lens shape having a convex surface protruding from a planar portion of the substrate portion 1 . The shape of the lens portion 10 is not particularly limited, and may be appropriately deformed depending on the application or the like.

[0057] A wafer-level lens array is obtained by molding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com