High pressure sodium vapour lamp

A high-pressure sodium and steam technology, which is applied in the direction of discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., can solve the problems of increased lamp voltage deviation and prolonged stabilization time, and achieve the effect of suppressing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

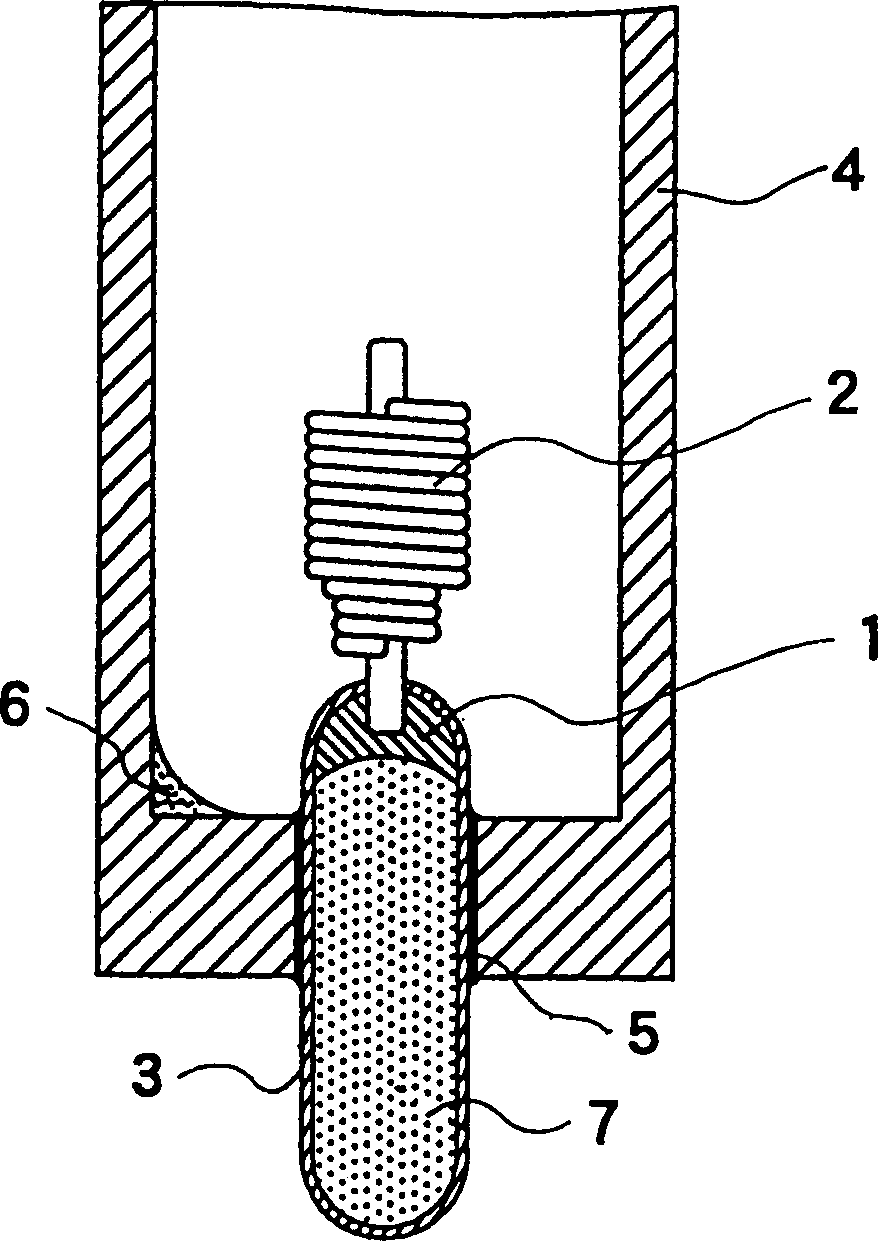

[0025] figure 1 It is a cross-sectional view showing the end structure of the light-emitting tube of a 150-watt high-pressure sodium vapor lamp with good lighting effect in an embodiment of the present invention. The structure of the luminous tube is that the conductive tube 3 supporting the electrode 2 is installed on both ends of the transparent alumina tube 4. in figure 1 In, only one end of the luminous tube is shown and the other end is omitted.

[0026] The electrode 2 with the electron radioactive material is fixed to one end of the conductive tube 3 in an airtight manner by the titanium brazing flux 1. The other end of the conductive tube 3 is closed, and the conductive tube 3 thus maintains an airtight structure. In the conductive tube 3, argon gas of 10 Torr at room temperature is enclosed as an inert gas. The conductive tube 3 is made of an alloy containing 99% niobium and 1% zirconium, and its outer diameter is 4 mm.

[0027] The installation part of the conductive ...

no. 2 example

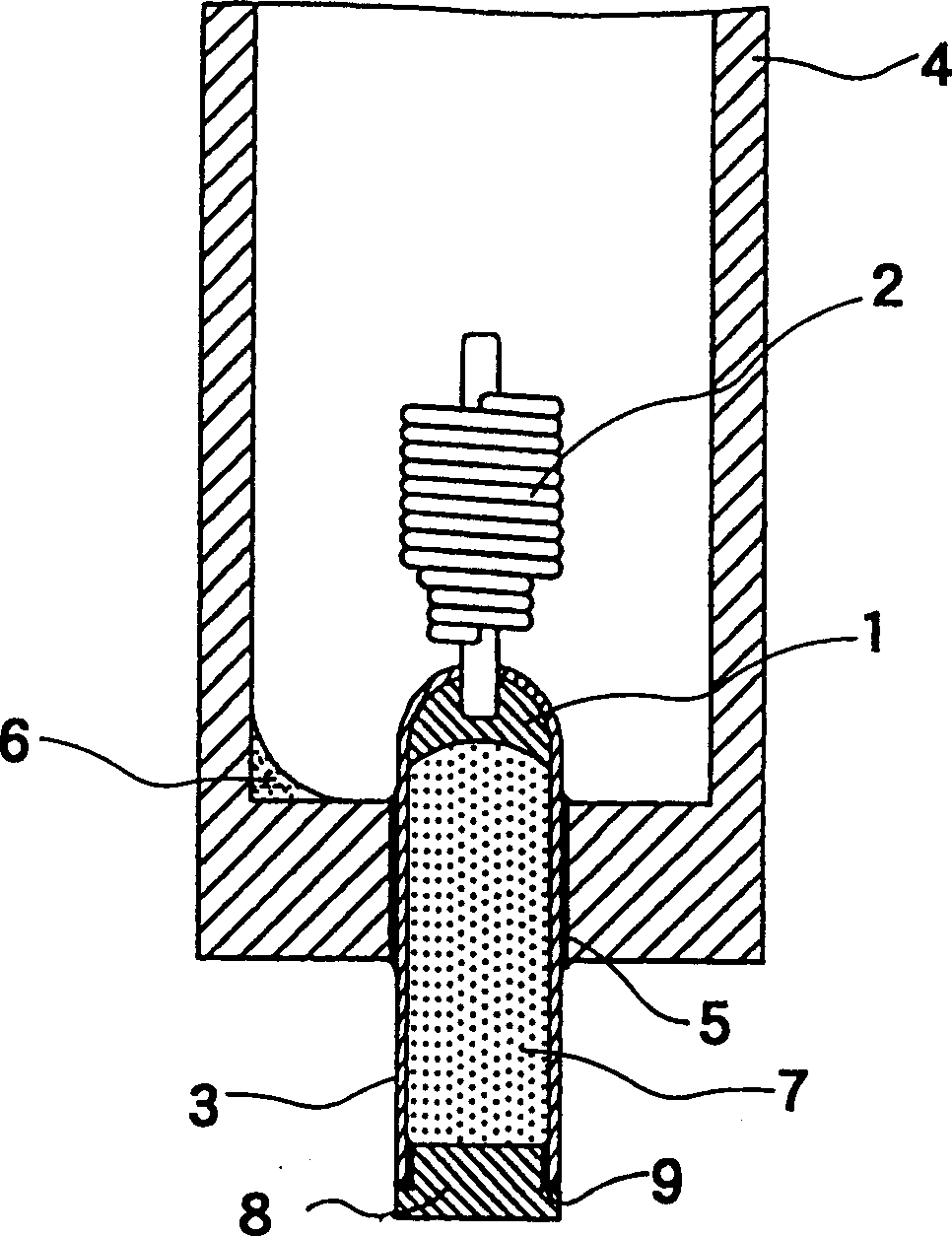

[0038] figure 2 It is a cross-sectional view showing the end structure of the light-emitting tube of a 150-watt high-pressure sodium vapor lamp with good lighting effect in another embodiment of the present invention. The luminous tube of the sodium vapor lamp of this embodiment is constructed in such a way that the opposite end of the electrode holding side of the conductive tube 3 is sealed with a ceramic cover 8 and a plugging agent 9 composed of ceramic glue, and an inert gas is sealed inside. The structure of the other parts is the same as the luminous tube of the sodium vapor lamp of the first embodiment.

[0039]In this way, an inert gas (argon) is enclosed at both ends of the conductive tube 3, and the conductive tube 3 is hermetically sealed in the light-transmitting alumina tube 4 with a plugging agent 5 to form a luminous tube. Prevents light color changes and lamp voltage changes in the course, shortens the time from lighting to lighting stabilization, and further sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com