System for drying and treating sludge by utilizing afterheat to generate high-temperature circulating air

A technology of high-temperature circulation and treatment system, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of increasing manufacturing cost, reduce manufacturing precision requirements, reduce equipment investment, and save fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following embodiments are specially cited in conjunction with the drawings, and detailed descriptions are made as follows.

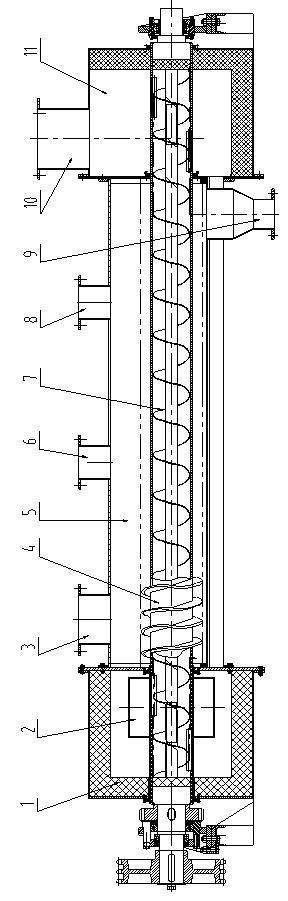

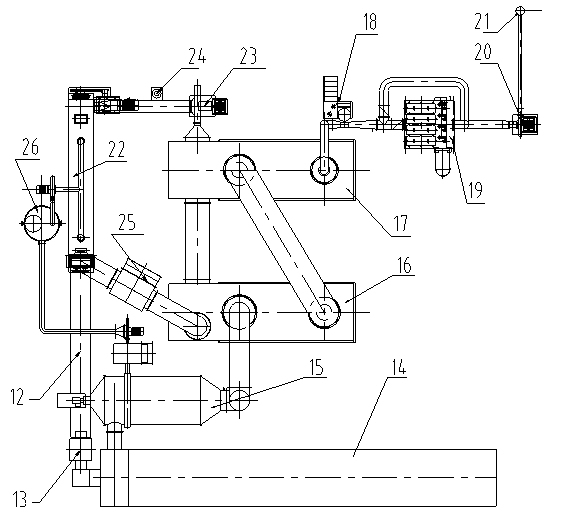

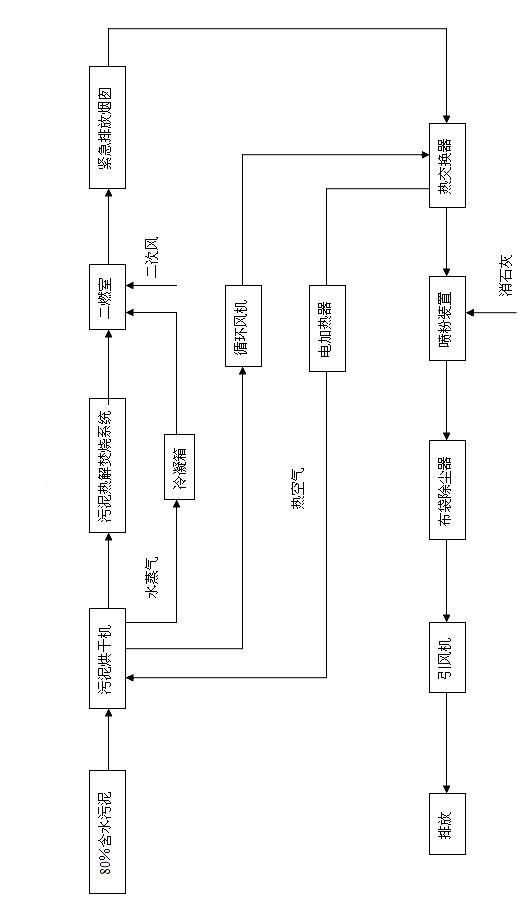

[0021] Please refer to the attached figure 1 with figure 2 , The sludge drying and processing system of the present invention that uses waste heat to generate high-temperature circulating air includes a sludge dryer 22 with a sludge screw conveying mandrel 4 inside. The axis of the screw conveying mandrel 4 is a spiral The air duct can pass high-temperature air, so that the high-temperature air can exchange indirect heat with the sludge enough; one end of the sludge spiral conveying mandrel is provided with a high-temperature air intake chamber 11, which is provided above the intake chamber 11 There is a thermal circulation air inlet 10, this form has a large air storage capacity, and also solves the problem of air inlet and outlet connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com