High performance concrete inorganic environmental waterproof expanding agent and preparation method thereof

A technology of high-performance concrete and expansion agent, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., and can solve the problems of not reaching the designed service life, accelerating the corrosion and destruction of steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 20 kg of cement, 0.3 kg of aluminum sulfate, 5.6 kg of potassium aluminum sulfate, 1.5 kg of ferrous sulfate, 0.2 kg of sodium chloride, 0.2 kg of urea, 0.2 kg of sodium sulfate, 40 kg of gypsum, and 32 kg of fly ash;

[0027] These raw materials are ground into powders with a particle size of 100-150 meshes; then the raw material powders are mixed and stirred evenly to prepare a high-performance concrete inorganic environmental protection waterproof expansion agent.

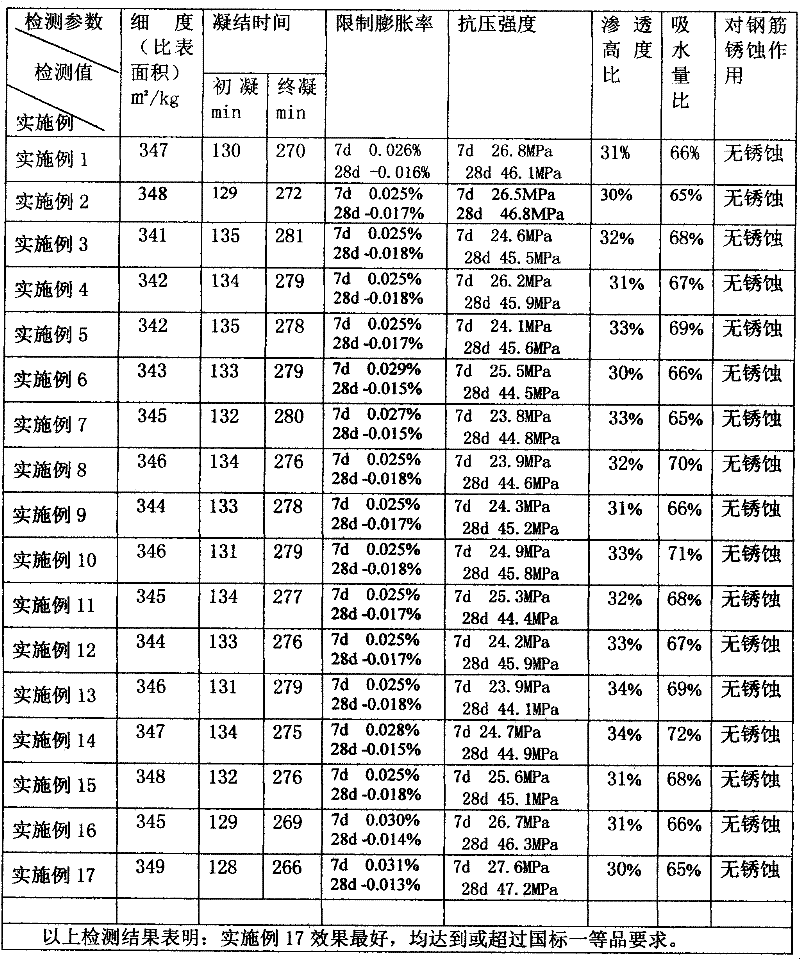

[0028] The prepared high-performance concrete inorganic environmental protection waterproof expansion agent is mixed in the concrete according to 8% by mass of the cement content in the cement concrete, and made into 10 test blocks, and the average index for detecting the performance of the 10 test blocks is: Degree (specific surface area): 347m 2 / kg, setting time: initial setting 130min, final setting 270min, limiting expansion rate: 7d 0.026% 28d-0.016%, compressive strength: 7d 26.8MPa 28d 46.1MP...

Embodiment 2-17

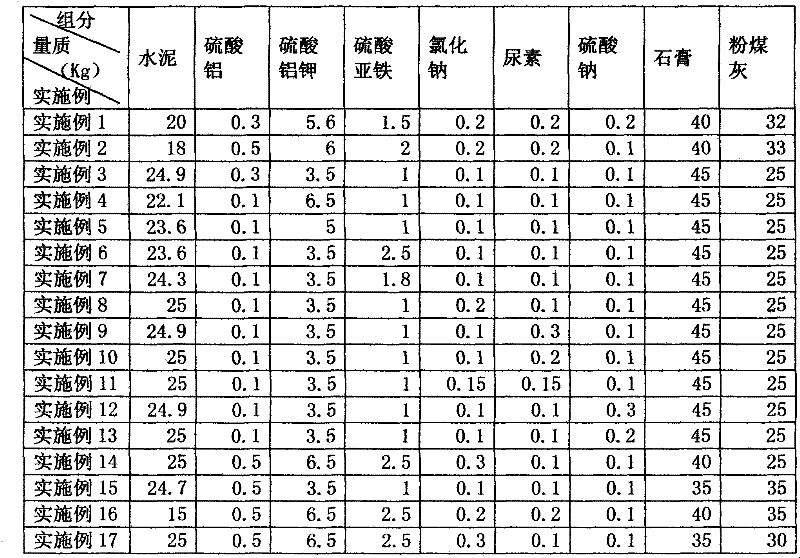

[0030] The raw materials and quality used in embodiment 2-17 are as shown in table 1 below, and its preparation method and detection method are identical with embodiment 1; Table 1 below shows the concrete raw material and quality used in embodiment 1-17 Wherein the cement described in embodiment 4-10 is 32.5 grade ordinary Portland cement, and described fly ash is I grade fly ash (according to GB / T 1596-2005 national standard). The following table 2 shows the detection data of the high-performance concrete inorganic environmental protection waterproof expansion agent obtained in Examples 1-17 after use. As can be seen from the detected data, the high-performance concrete inorganic environmental protection waterproof expansion agent of the present invention has high efficiency. Waterproof, moisture-proof, expansion, anti-crack, anti-seepage and other functions, no corrosion effect on steel bars, and can achieve permanent structural self-waterproof, which is a major technologica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com