Method for separating diisopropylbenzene isomeride by virtue of reduced pressure batch distillation

A technology of isomers and diisopropylbenzene, applied in distillation purification/separation, organic chemistry and other directions, can solve the problems of low relative volatility, long operation time and high energy consumption, and achieve low energy consumption and operation time. The effect of short and low column temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

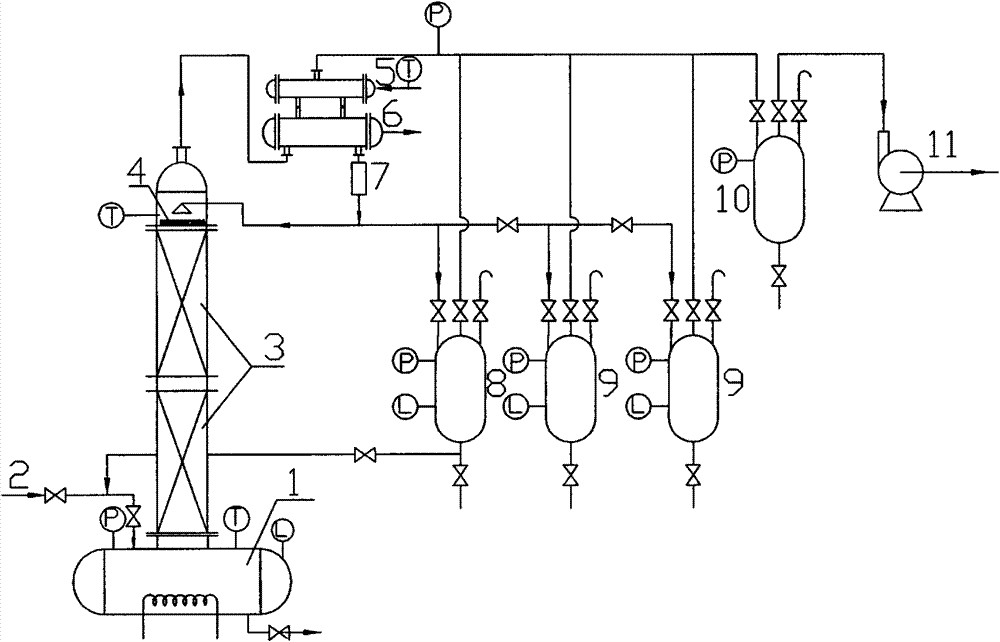

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] like figure 1 As shown, a kind of device of vacuum batch rectification separation dicumyl isomer of the present invention comprises tower still 1, feed port 2, rectifying tower 3, liquid distributor 4, catcher 5, A batch rectification tower composed of a condenser 6 and a reflux tank 7; wherein one end of the reflux line of the reflux tank 7 is connected to the top of the rectification tower, and the other end is connected to the overhead product transition fraction tank 8 and the tower top product tank 9, and a vacuum pump 11 The trap 5 is connected to the overhead product transition fraction tank 8 and the overhead product tank 9 through a buffer tank 10 respectively.

[0018] Attached below figure 1 The vacuum distillation process flow of the separation device and method for the separation of dicumyl isomers by vacuum batch distillat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com