Aquogel scalding surgical dressing and preparation method thereof

A hydrogel and dimethyl sulfone technology, applied in the field of biochemistry, can solve the problems of low healing effect of scald wound, long wound healing time, and great pain of patients, and achieve accelerated wound healing, good biocompatibility and Wettability, pain-reducing effects for patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention discloses a preparation method of a hydrogel burn dressing, comprising the following steps:

[0030] a), adding dimethyl sulfone to the polyethylene solution to obtain a mixed solution, the weight ratio of dimethyl sulfone to polyvinyl alcohol in the mixed solution is (0.01~10):100;

[0031] b), casting the mixed solution into a film;

[0032] c) performing repeated freezing and cross-linking on the cast film-forming solution to obtain a hydrogel burn dressing.

[0033] It can be seen from the above scheme that the method provided by the invention is to prepare a hydrogel dressing with polyvinyl alcohol (PVA) and dimethyl sulfone (MSM) as raw materials. The reason for the PVA selected by the present invention is: PVA has good biodegradability, biocompatibility, solvent resistance and film-forming property, has no toxic and side effects to the human body, and is an excellent biomedical material, so the present invention selects P...

Embodiment 1

[0047] 1. Prepare PVA solutions with a concentration of 8wt%, 12wt% and 15wt%, respectively, and heat to 100°C while stirring to completely dissolve the PVA in water.

[0048] 2. Freeze the three PVA solutions prepared in step 1 at -20°C for 20 hours, then take them out and thaw them at room temperature for 2 hours, repeat freezing and cross-linking 6 times in this way, and obtain PVA with concentrations of 8wt%, 12wt% and 15wt% respectively Hydrogel dressing.

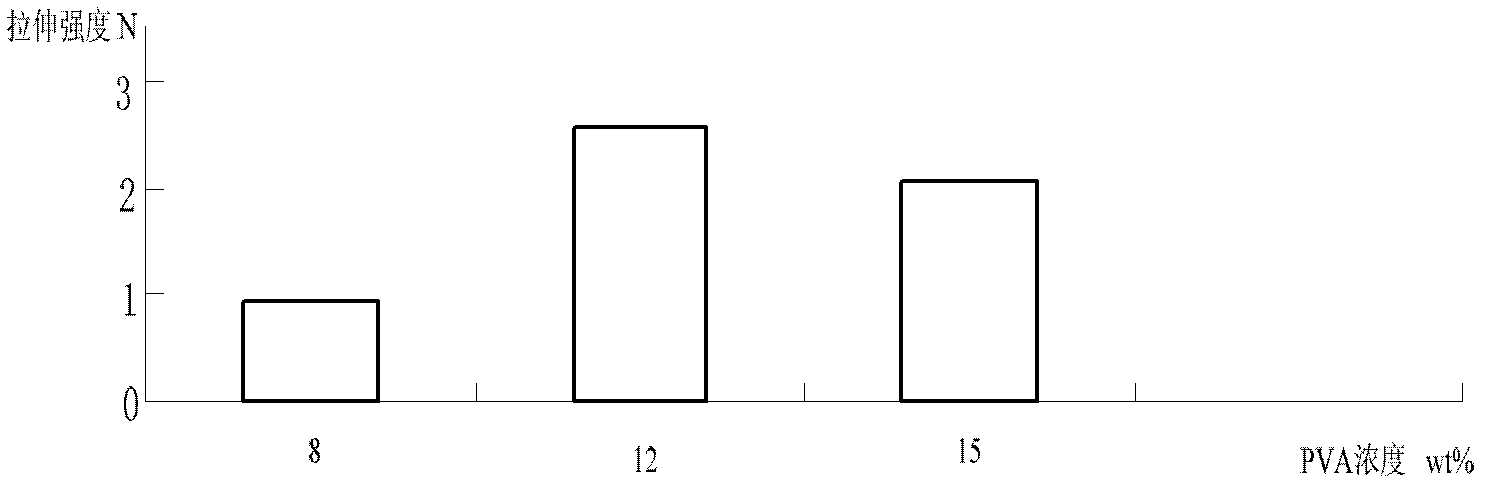

[0049] Test the extensional stretch properties of the above three PVA hydrogel dressings, such as figure 1 Shown is the concentration of 8wt%, 12wt% and 15wt% of the PVA hydrogel dressing tensile strength histogram, as can be seen from the figure, 12wt% of the PVA hydrogel dressing has good elongation and tensile properties.

Embodiment 2

[0051] 1. Prepare a PVA solution with a concentration of 12wt%, and heat it to 100°C while stirring to completely dissolve the PVA, and cool the PVA solution to room temperature.

[0052] 2. In the state of slow stirring, add the MSM solution drop by drop into the PVA solution. The weight ratio of the MSM in the added MSM solution to the PVA in the PVA solution is 0.01:100. Soak to obtain a clear mixed solution.

[0053] 3. Pour the mixed solution obtained in step 3 into a film-making dish to cast a film.

[0054] 4. Freeze the film-forming solution in a refrigerator at -20°C for 20 hours, remove and thaw at room temperature for 2 hours, and repeat this 6 times to obtain a hydrogel burn dressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com