Electric control safety system for slurry pump

A safety system and mud pump technology, applied in the field of mud pump electric control safety system, can solve problems such as soaring pump pressure and safety accidents, and achieve the effects of accurate pressure detection, guaranteeing production safety, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

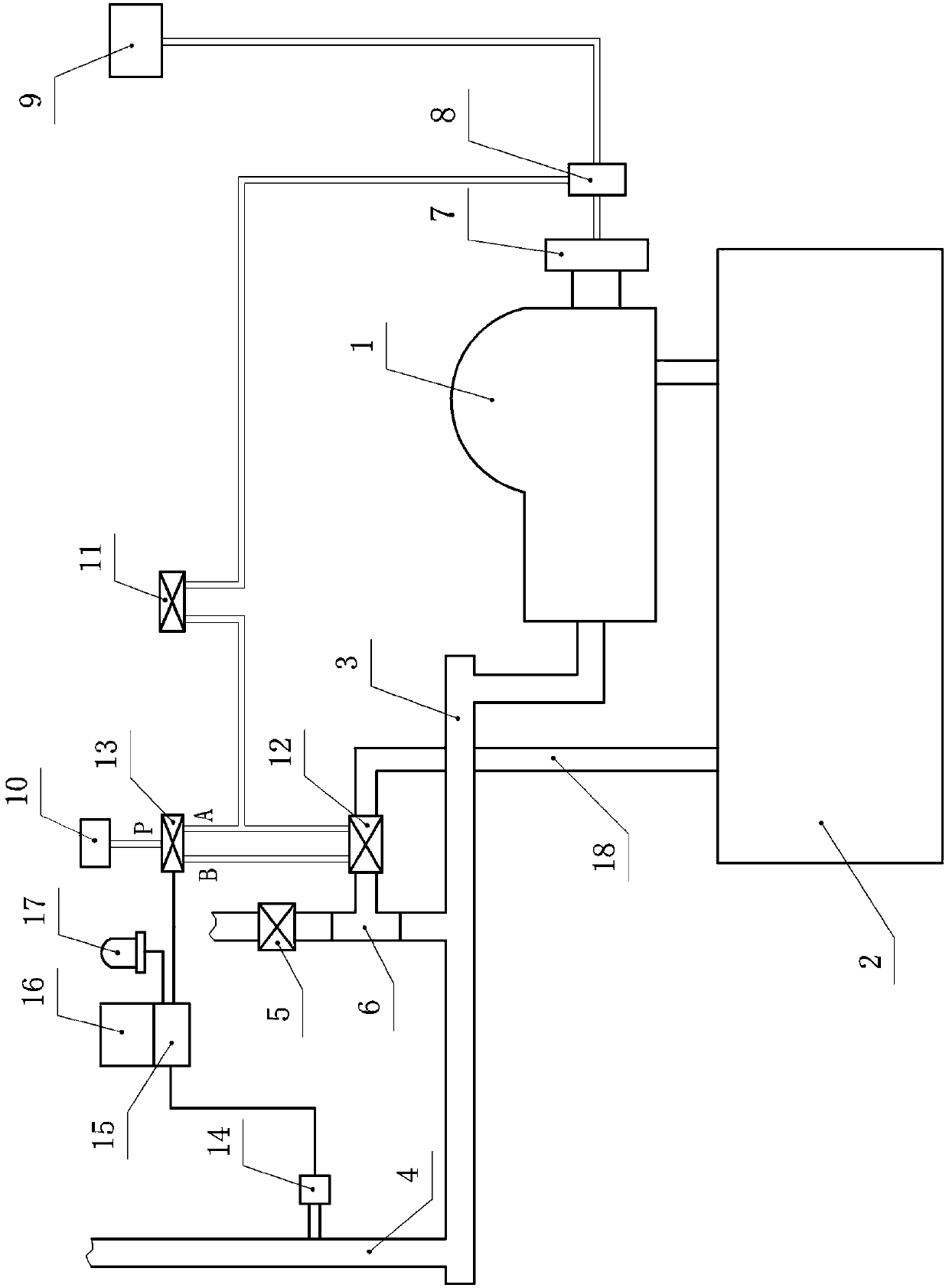

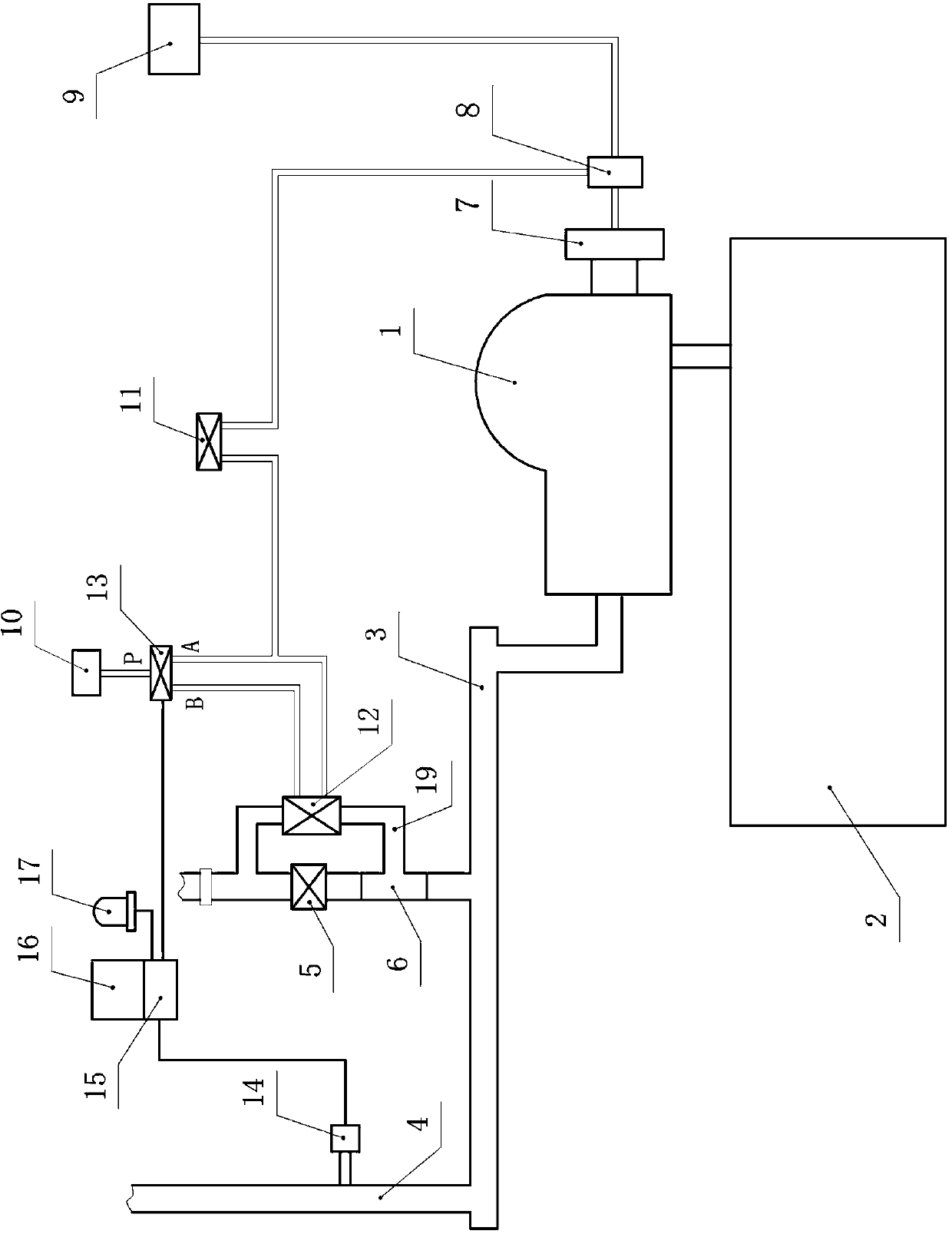

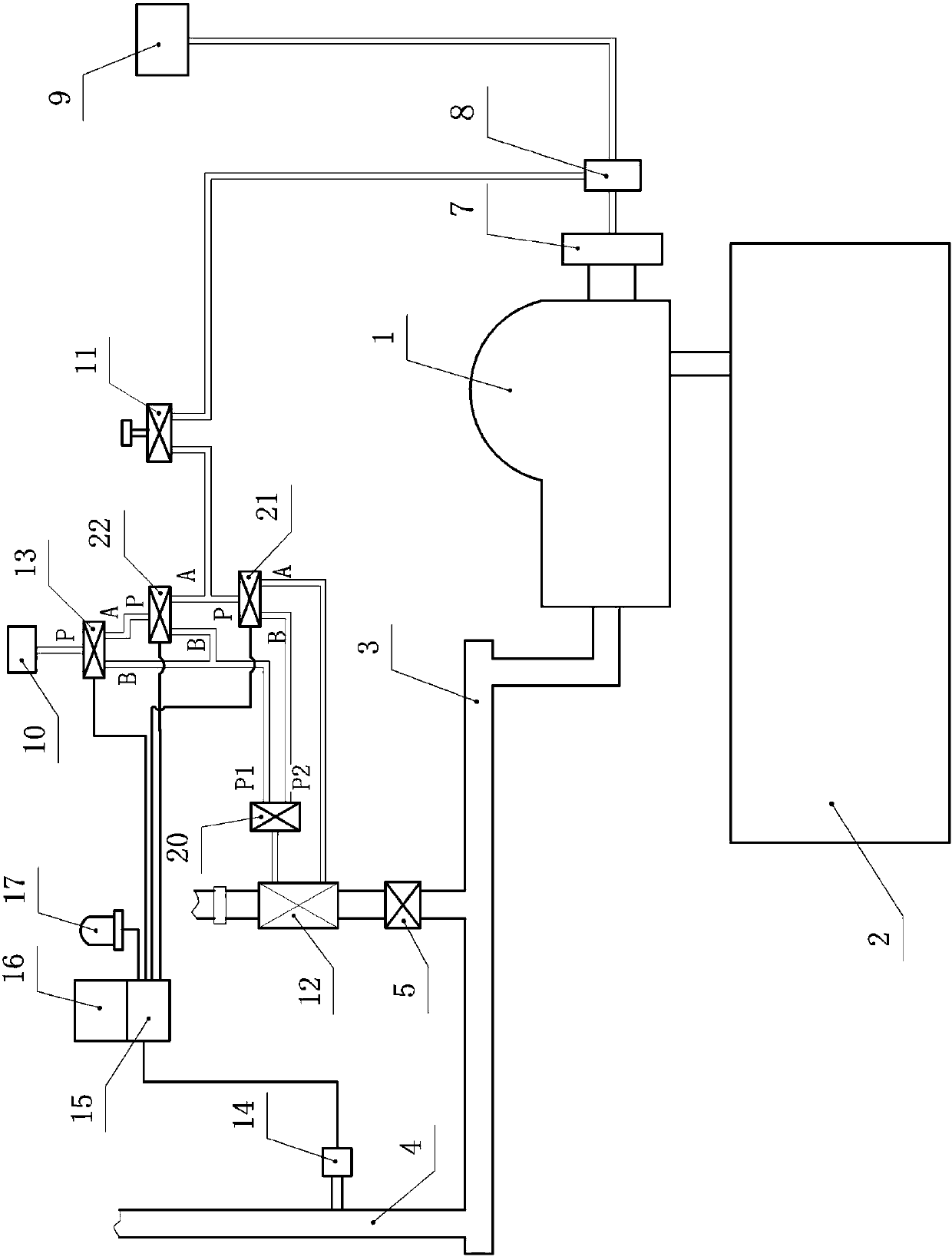

[0024] Embodiment one: see figure 1 , figure 2. The mud pump electronic control safety system of the present invention includes a pressure sensor 14, an embedded integrated touch screen industrial computer 16 and a program controller (PLC) 15, a normally closed pneumatic shut-off valve 12, and a pressure sensor 14 installed in the high-pressure mud of the mud pump 1. On the outlet pipeline 3, the output signal of the pressure sensor 14 is connected to the input signal acquisition port of the PLC, and the PLC is connected to the embedded integrated touch screen industrial computer 16 for communication, and the PLC is equipped with an output port to control the connection (through the electromagnetic head) normally closed pneumatic shut-off valve 12 The electromagnetic reversing valve 13, the air source inlet of the electromagnetic reversing valve 13 is connected to the control air source 10, and the two outlets of the electromagnetic reversing valve 13 are respectively connec...

Embodiment 2

[0026] Embodiment two: see figure 1 or figure 2 , the electric control safety system of the mud pump in this embodiment is different from the first embodiment in that the electromagnetic reversing valve 13 adopts a two-position five-way electromagnetic valve, the inlet P of the electromagnetic valve is connected to the control air source, and one of its normally open outlets A, A normally closed outlet B is respectively connected to the working cylinders at both ends of the normally closed pneumatic valve 12, the normally open outlet A is connected to the closing interface of the normally closed pneumatic shut-off valve 12, and the normally closed outlet B is connected to the normally closed pneumatic valve 12. The start interface connection of shut-off valve 12.

Embodiment 3

[0027] Embodiment three: see figure 1 or figure 2 , the electric control safety system of the mud pump in this embodiment is different from the second embodiment in that an air source pipe is provided at the normally open outlet A of the electromagnetic reversing valve to connect with the manual switch control valve 11 that is connected to the mud pump; The inlet of the manual switch control valve 11 is connected to the normally open outlet A of the electromagnetic reversing valve, and the outlet of the manual switch control valve 11 is connected to the normally closed control air relay 8 to control the gas source inlet. That is, the normally open outlet A of the electromagnetic reversing valve 13 is divided into two paths, one path is connected to the inlet gas path of the manual switch control valve 11 that is connected to the mud pump 1, and the other path is connected to the closing interface of the normally closed pneumatic shut-off valve 12 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com