Control program modularization system for numerical control machine

A technology of numerical control machine tools and numerical control systems, applied in the direction of digital control, electrical program control, etc., can solve the problems that hinder the level of control program preparation, improve production debugging and equipment maintenance, communication barriers between control programs of numerical control machine tools, and difficulty in the control effect of numerical control machine tools and other issues to achieve the effect of good program structure, good portability and good readability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation plan

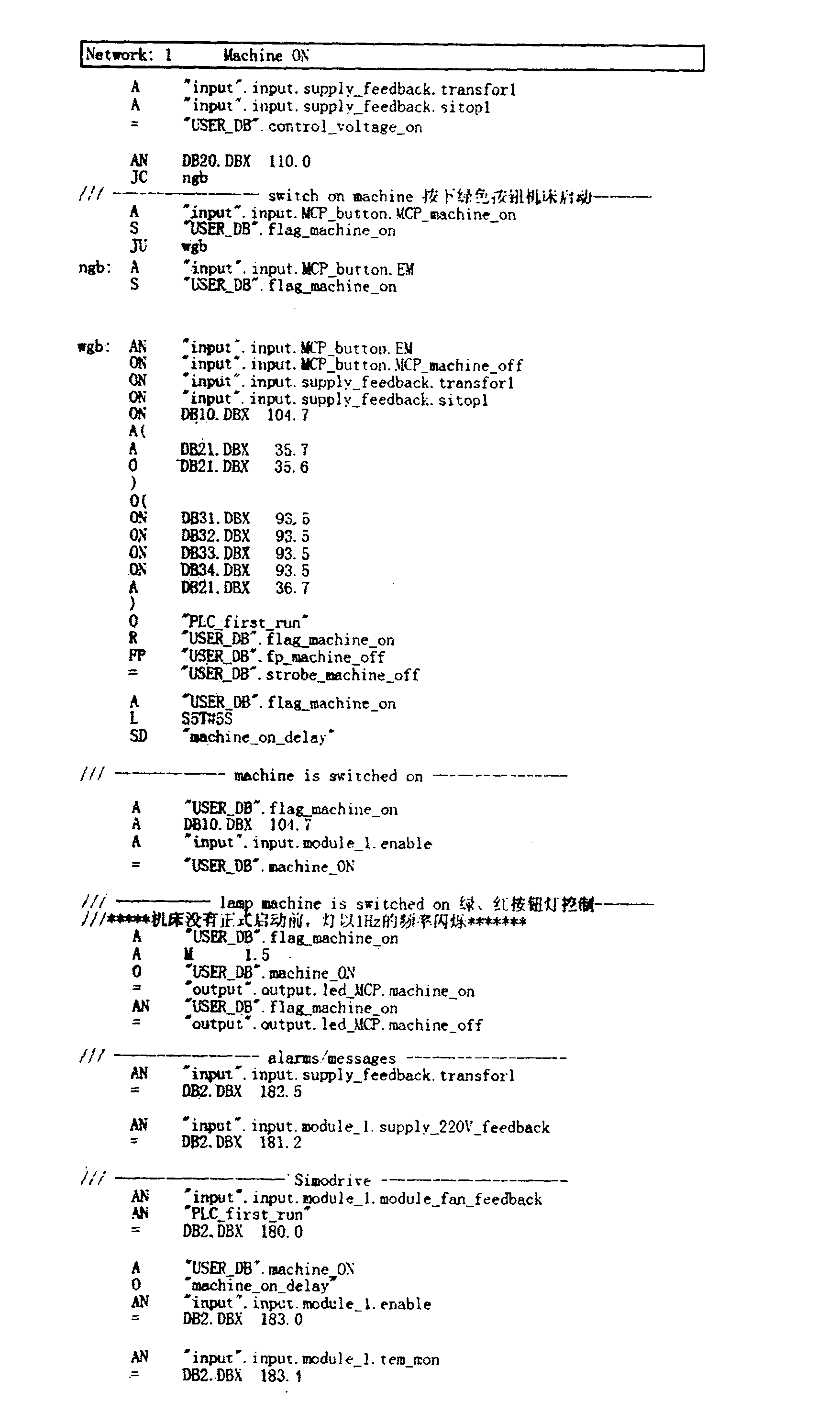

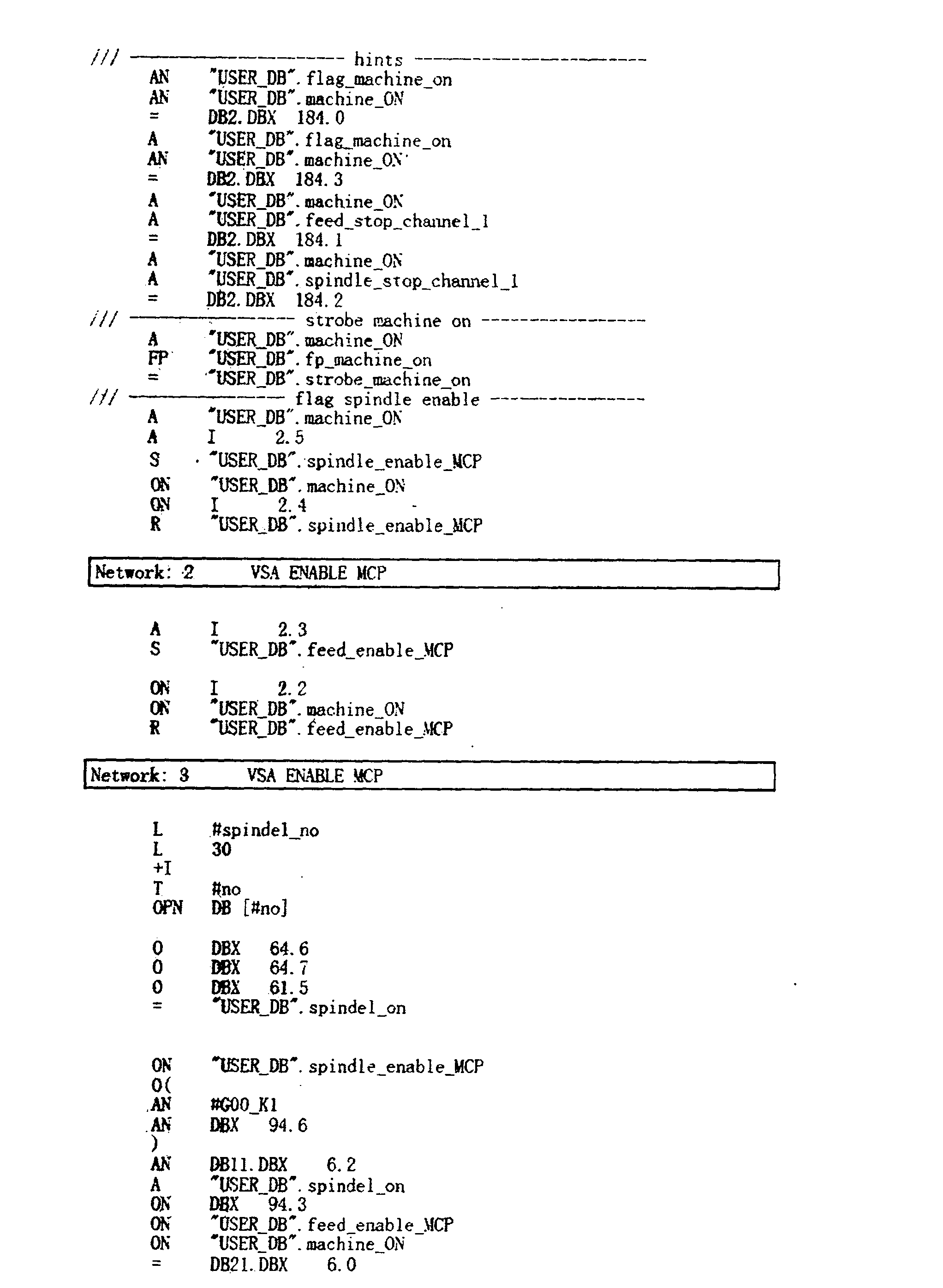

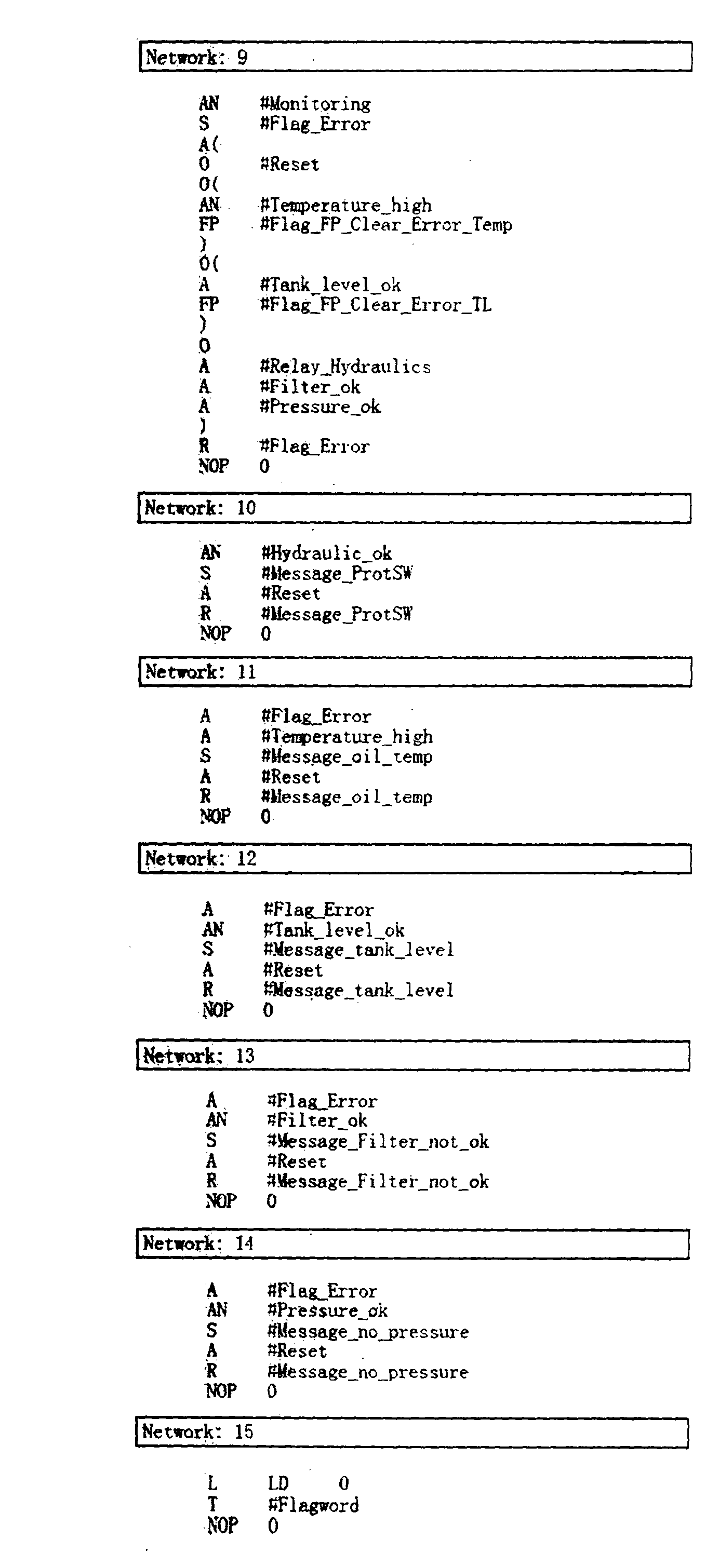

[0026] The CNC machine tool control program modular system uses a CNC machine tool with two hydraulic stations (Z-axis balance hydraulic station and loose / clamp tool control hydraulic station) as a simple example to illustrate the specific application process of the present invention. In this example, all programs and applications are compiled based on Siemens 840D CNC system, which is commonly used in CNC machine tools.

[0027] like figure 1 As shown, the man-machine interface of the CNC machine tool is connected to the NCU unit of the CNC system through the MPI bus, and the servo unit of the CNC system is connected to the NCU unit of the CNC system through the drive bus and the device bus respectively, and the NCU unit of the CNC system is connected to the input and output modules through the profibus bus.

[0028] In the CNC system NCU unit such as figure 2 As shown, the CNC machine tool control program system of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com